Content .. 1055 1056 1057 1058 ..

Opel Frontera UE. Manual - part 1057

CLUTCH

7C–19

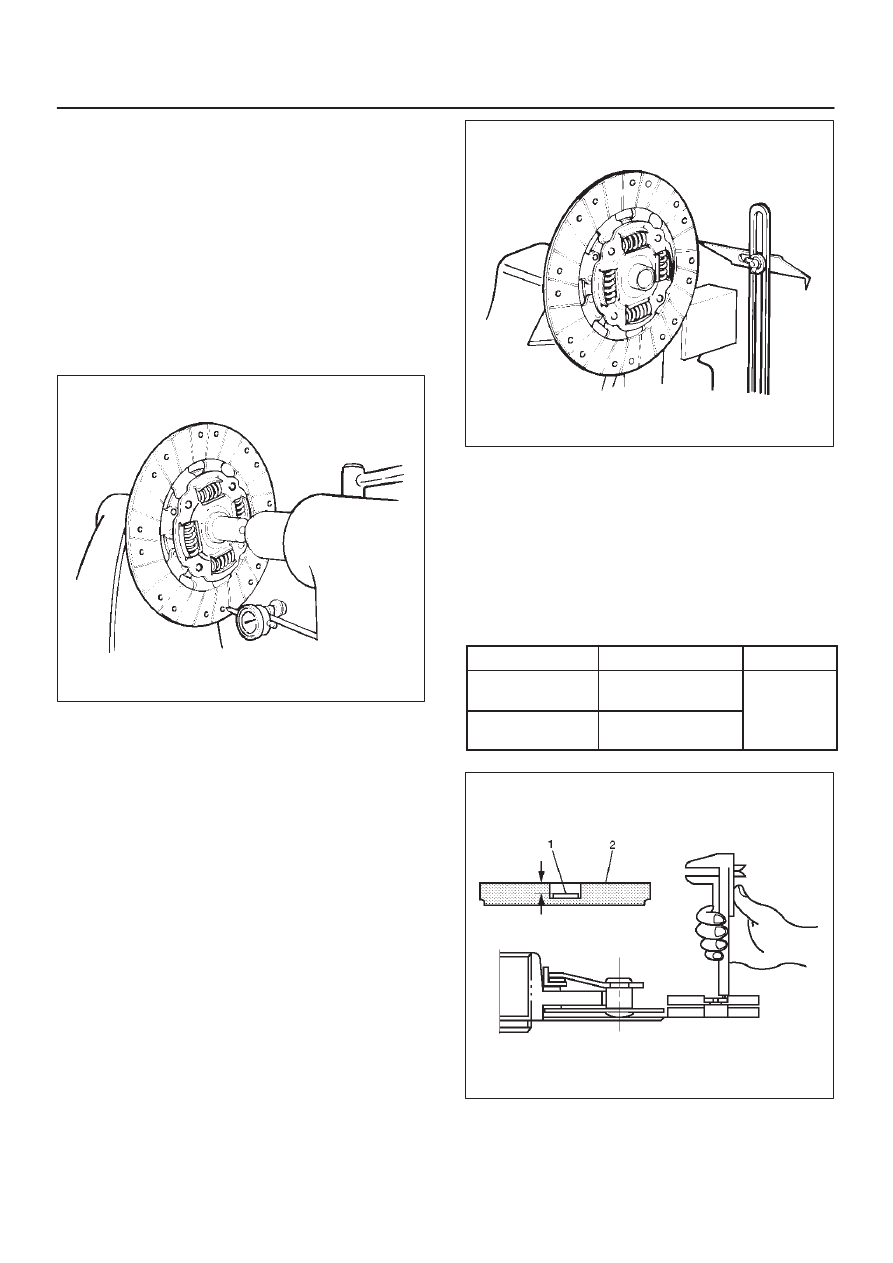

Driven Plate Warpage

1. Insert the clutch pilot aligner J–24547 into the driven

plate splined hub. The clutch pilot aligner must be

held perfectly horizontal.

2. Set a dial indicator to the driven plate outside

circumference.

3. Slowly turn the driven plate. Read the dial indicator as

you turn the driven plate. If the measured value

exceeds the specified limit, the driven plate assembly

must be replaced.

Driven Plate Warpage

Standard: 0.7mm (0.028in)

Limit: 1.0mm (0.039in)

201RS008

Driven Plate Splined Hub Spline Wear

1. Clean the driven plate splined hub.

2. Install the driven plate to the transmission top gear

shaft spline.

3. Set a surface gauge to the driven plate outside

circumference.

4. Slowly turn the driven plate counterclockwise.

Measure the spline rotation play as you turn the

driven plate. If the measured value exceeds the

specified limit, the driven plate assembly must be

replaced.

Driven Plate Warpage

Standard: 0.5mm (0.020in)

Limit: 1.0mm (0.039in)

201RS009

Rivet Head Depression

D

Use a depth gauge or a straight edge with steel rule to

measure the rivet head depression (1) from the facing

surface (2).

D

Be sure to measure the rivet head depression on both

sides of the driven plate. If the measured value is less

than the specified limit, the driven plate assembly

must be replaced.

Rivet Head Depression

Standard

Limit

Fly wheel side

1.2–1.8mm

(0.047–0.071in)

0.2mm

Pressure plate

side

1.6–2.2mm

(0.062–0.087in)

(0.008in)

201RS010