Nissan Frontier D40. Manual - part 620

EM-212

< REMOVAL AND INSTALLATION >

[VQ40DE]

ENGINE ASSEMBLY

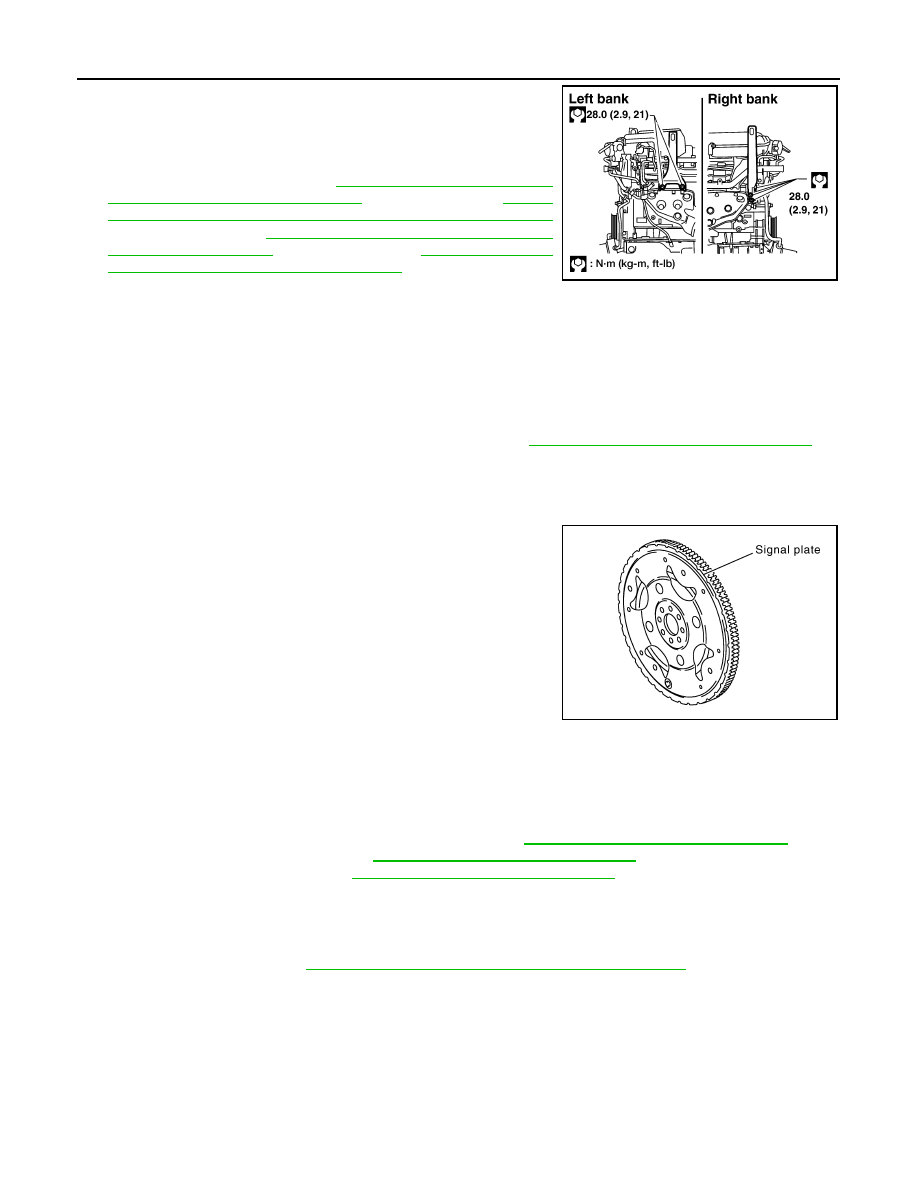

29. Install engine slingers into left bank and right bank.

30. Remove front frame crossmember.

31. Remove transmission. Refer to

tion from Vehicle (For 2WD Models)"

(2WD M/T models)

"Removal and Installation from Vehicle (For 4WD Models)"

TM-301, "Removal and Installation for

(2WD A/T models),

and Installation for VQ40DE 4WD Models"

(4WD A/T models).

32. Lift with hoist and secure the engine in position.

33. Remove engine assembly from vehicle, avoiding interference with vehicle body.

CAUTION:

• Before and during this lifting, always check if any harnesses are left connected.

34. Remove the parts that may restrict installation of engine to engine stand.

NOTE:

The procedure is described assuming that you use a engine holding the surface, to which transmission is

installed.

a.

Remove clutch cover and clutch disc (M/T models). Refer to

CL-23, "6M/T : Removal and Installation"

b.

Remove flywheel (M/T models) or drive plate (A/T models).

• Holding crankshaft pulley bolts, lock crankshaft to remove flywheel or drive plate bolts.

• Loosen bolts diagonally.

CAUTION:

• Be careful not to damage or scratch drive plate (A/T

models) and contact surface for clutch disc of flywheel

(M/T models). Especially avoid deforming and damaging

of signal plate teeth (circumference position).

• Do not disassemble drive plate.

• Place the drive plate with signal plate surface facing

other than downward.

• Keep magnetic materials away from signal plate.

CAUTION:

Use an engine stand that has a load capacity [approximately 240kg (529 lb) or more] large enough

for supporting the engine weight.

• If the load capacity of the stand is not adequate, remove the following parts beforehand to

reduce the potential risk of overturning the stand.

- Remove fuel tube and fuel injector assembly. Refer to

EM-159, "Removal and Installation"

- Remove intake manifold. Refer to

EM-143, "Removal and Installation"

.

- Remove rocker cover. Refer to

EM-155, "Removal and Installation"

.

- Other removable brackets.

CAUTION:

Before removing the hanging chains, make sure the engine stand is stable and there is no risk of

overturning.

35. Remove generator. Refer to

CHG-21, "Removal and Installation - VQ40DE Models"

.

36. Remove engine mounting insulator bracket (upper) with power tool.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• When replacing an engine or transmission you must make sure the dowels are installed correctly

during reassembly.

• Improper alignment caused by missing dowels may cause vibration, oil leaks or breakage of driv-

etrain components.

Engine slinger torque:

28.0 N·m (2.9 kg-m, 21 ft-lb)

WBIA0624E

KBIA2491E