Nissan Frontier D40. Manual - part 591

EM-96

< DISASSEMBLY AND ASSEMBLY >

[QR25DE]

ENGINE UNIT

CAUTION:

Do not rotate crankshaft.

• Remove connecting rod cap and bearing, and using the scale on

the plastigage bag, measure the plastigage width.

NOTE:

The procedure when the measured value exceeds the limit is

same as that described in the “Method by Calculation”.

MAIN BEARING OIL CLEARANCE

Method by Calculation

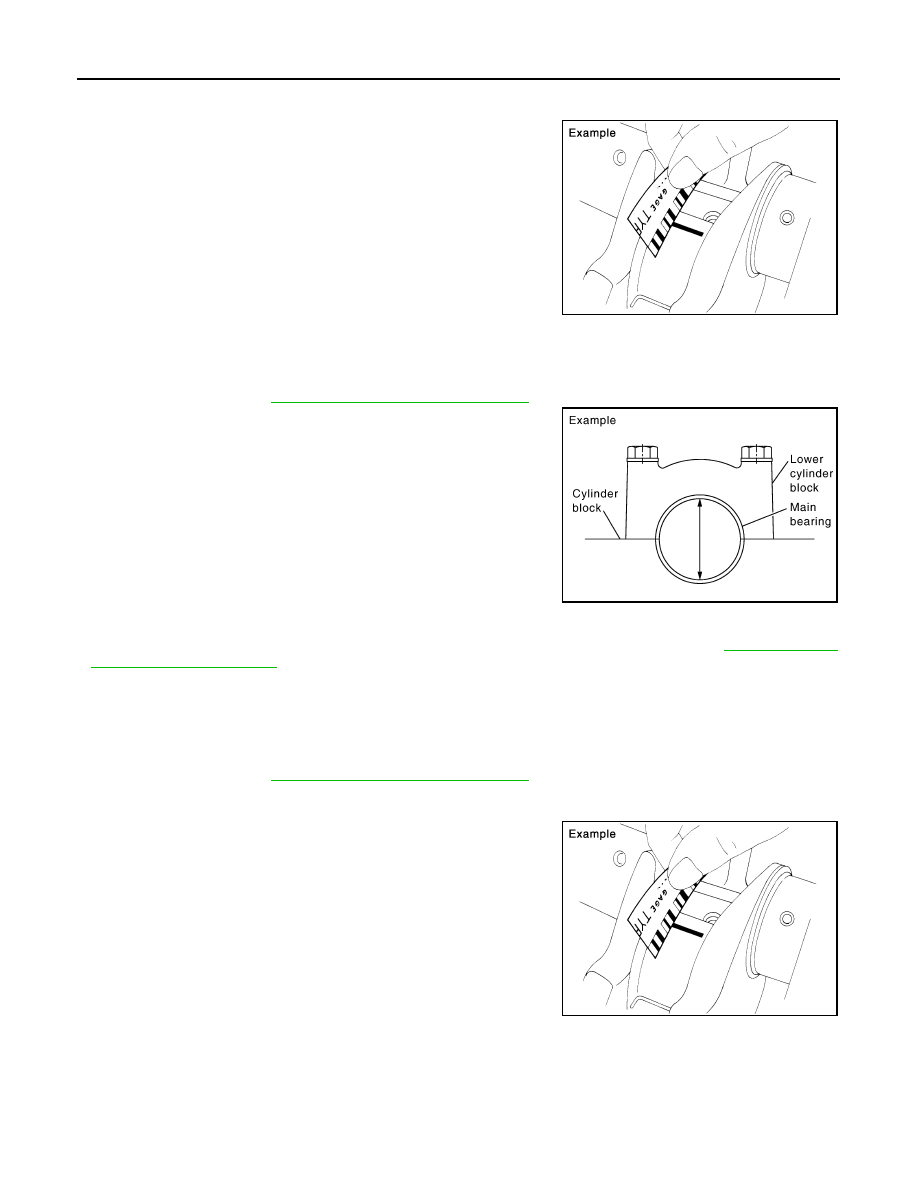

• Install main bearings to cylinder block and lower cylinder block, and tighten lower cylinder block bolts to the

specified torque. Refer to

EM-79, "Disassembly and Assembly"

• Measure the inner diameter of main bearing with a bore gauge.

(Bearing oil clearance) = (Main bearing inner diameter) – (Crank-

shaft main journal diameter)

• If the clearance exceeds the limit, select proper main bearing according to main bearing inner diameter and

crankshaft main journal diameter to obtain the specified bearing oil clearance. Refer to

.

Method of Using Plastigage

• Remove engine oil and dust on crankshaft main journal and the surfaces of each bearing completely.

• Cut a plastigage slightly shorter than the bearing width, and place it in crankshaft axial direction, avoiding oil

holes.

• Install main bearings to cylinder block and lower cylinder block, and tighten lower cylinder block bolts to the

specified torque. Refer to

EM-79, "Disassembly and Assembly"

CAUTION:

Do not rotate crankshaft.

• Remove lower cylinder block and bearings, and using the scale on

the plastigage bag, measure the plastigage width.

NOTE:

The procedure when the measured value exceeds the limit is

same as that described in the “Method by Calculation”.

MAIN BEARING CRUSH HEIGHT

PBIC1149E

Standard:

No. 1, 3 and 5 journals

: 0.028 - 0.042 mm (0.0011 - 0.0017 in)

No. 2 and 4 journals

: 0.041 - 0.056 mm (0.0016 - 0.0022 in)

Limit

: 0.1 mm (0.004 in)

PBIC2204E

PBIC1149E