Nissan Frontier D40. Manual - part 564

NORMAL OPERATING CONDITION

EC-947

< SYMPTOM DIAGNOSIS >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

NORMAL OPERATING CONDITION

Fuel Cut Control (at No Load and High Engine Speed)

INFOID:0000000005273903

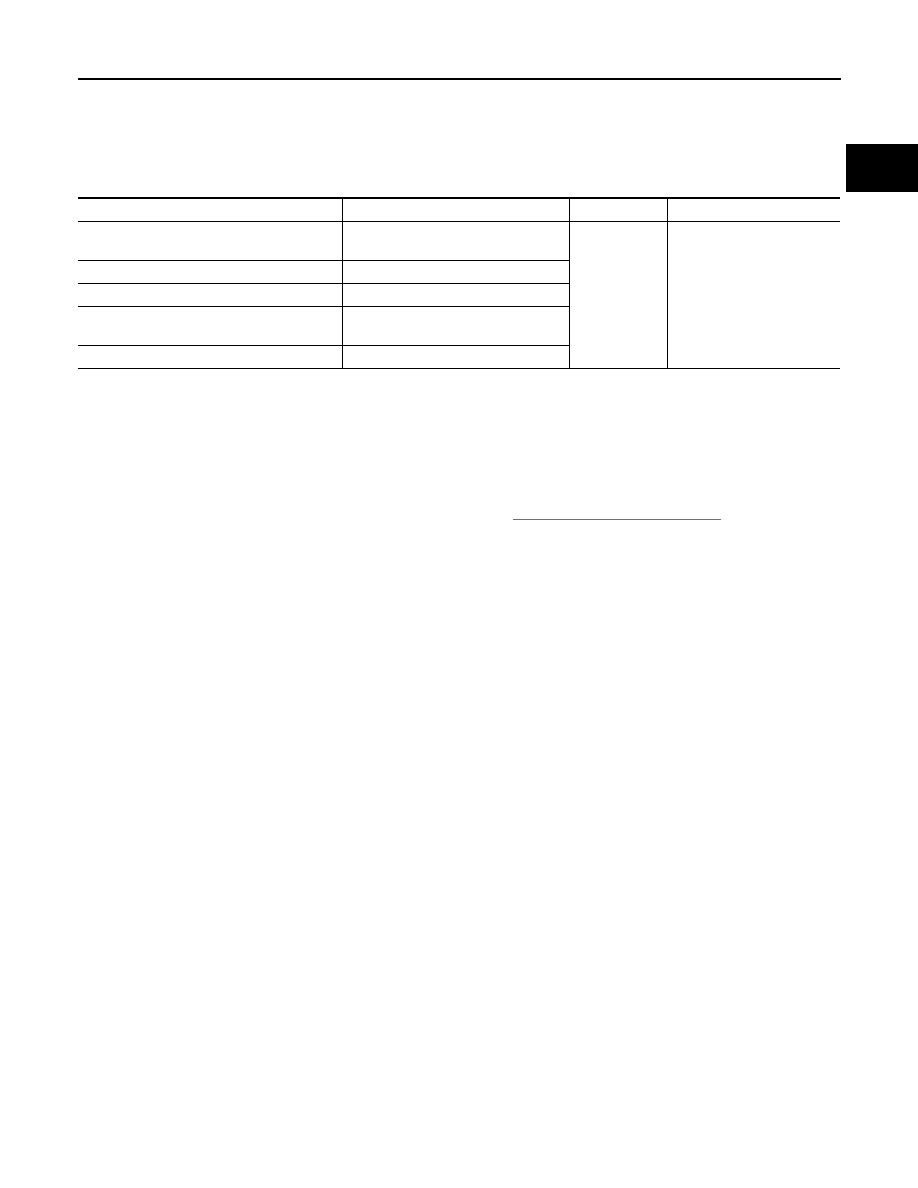

INPUT/OUTPUT SIGNAL CHART

*: This signal is sent to the ECM through CAN communication line.

SYSTEM DESCRIPTION

If the engine speed is above 1,800 rpm under no load (for example, the shift position is neutral and engine

speed is over 1,800 rpm) fuel will be cut off after some time. The exact time when the fuel is cut off varies

based on engine speed.

Fuel cut will be operated until the engine speed reaches 1,500 rpm, then fuel cut will be cancelled.

NOTE:

This function is different from deceleration control listed under

.

Sensor

Input Signal to ECM

ECM function

Actuator

Park/neutral position (PNP) switch (M/T)

TCM (A/T)

Neutral position

Fuel cut control

Fuel injector

Accelerator pedal position sensor

Accelerator pedal position

Engine coolant temperature sensor

Engine coolant temperature

Crankshaft position sensor (POS)

Camshaft position sensor (PHASE)

Engine speed

Wheel sensor

Vehicle speed*