Nissan Frontier D40. Manual - part 507

P0453 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-719

< COMPONENT DIAGNOSIS >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

• Harness for open or short between EVAP control system pressure sensor and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

9.

CHECK RUBBER TUBE

1.

Disconnect rubber tube connected to EVAP canister vent control valve.

2.

Check the rubber tube for clogging, vent and kinked.

OK or NG

OK

>> GO TO 10.

NG

>> Clean the rubber tube using an air blower, repair or replace rubber tube.

10.

CHECK EVAP CANISTER VENT CONTROL VALVE

EC-702, "Component Inspection"

OK or NG

OK

>> GO TO 11.

NG

>> Replace EVAP canister vent control valve.

11.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-720, "Component Inspection"

OK or NG

OK

>> GO TO 12.

NG

>> Replace EVAP control system pressure sensor.

12.

CHECK DRAIN FILTER

EC-720, "Component Inspection"

OK or NG

OK

>> GO TO 13.

NG

>> Replace drain filter.

13.

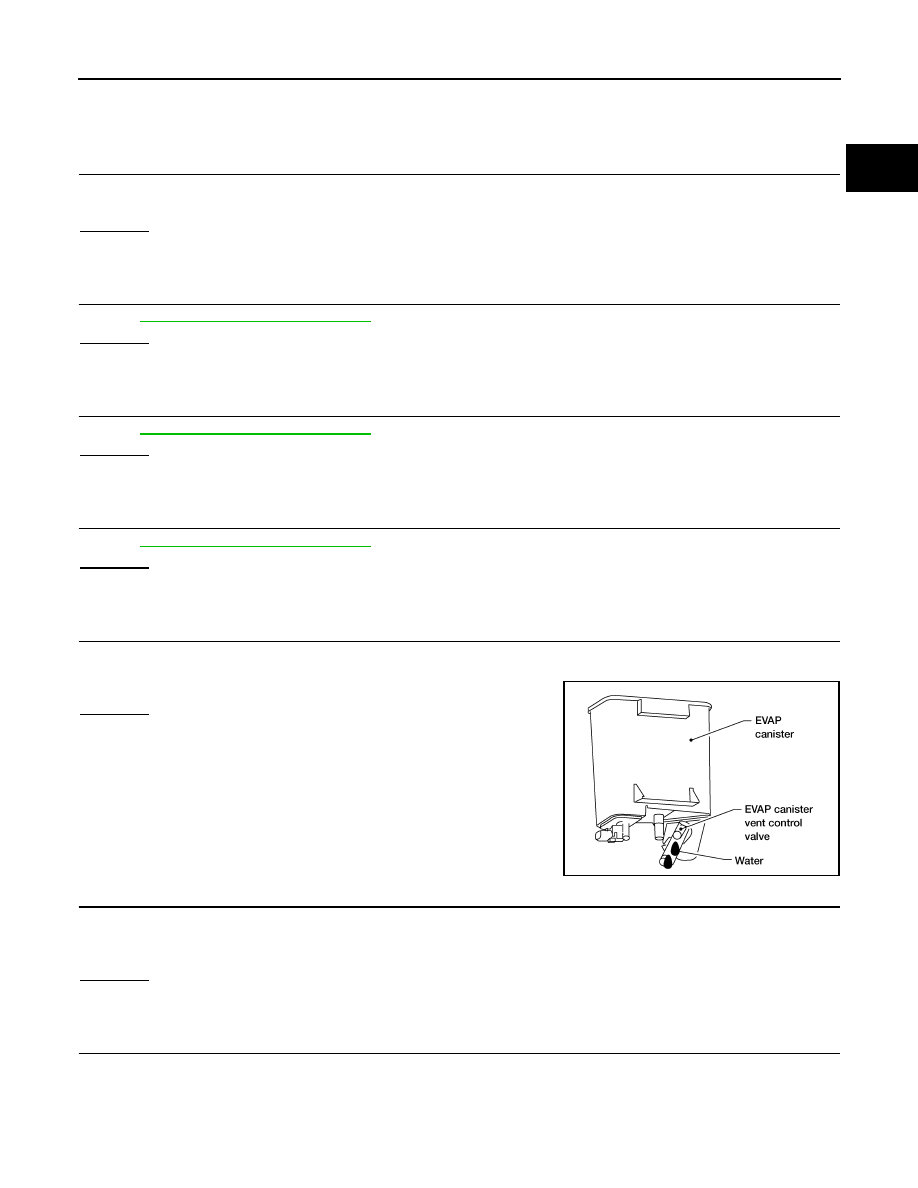

CHECK IF EVAP CANISTER IS SATURATED WITH WATER

1.

Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

2.

Check if water will drain from the EVAP canister.

Yes or No

Yes

>> GO TO 14.

No

>> GO TO 16.

14.

CHECK EVAP CANISTER

Weigh the EVAP canister with the EVAP canister vent control valve and EVAP control system pressure sensor

attached.

The weight should be less than 2.0 kg (4.4 lb).

OK or NG

OK

>> GO TO 16.

NG

>> GO TO 15.

15.

DETECT MALFUNCTIONING PART

Check the following.

• EVAP canister for damage

• EVAP hose between EVAP canister and drain filter for clogging or poor connection

BBIA0558E