Nissan Frontier D40. Manual - part 388

P0452 EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-243

< COMPONENT DIAGNOSIS >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

>> INSPECTION END

Component Inspection

INFOID:0000000005273242

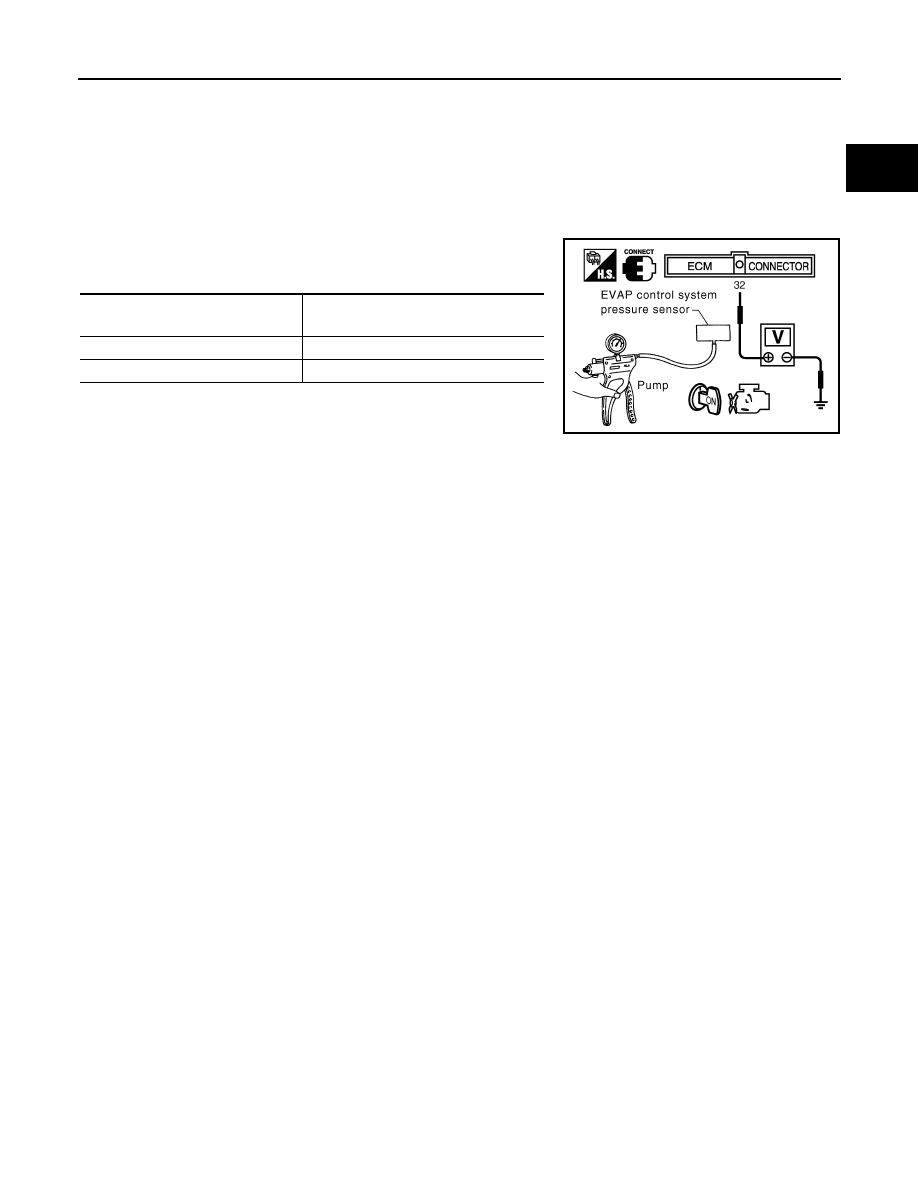

EVAP CONTROL SYSTEM PRESSURE SENSOR

1.

Remove EVAP control system pressure sensor with its harness connector.

Always replace O-ring with a new one.

2.

Install a vacuum pump to EVAP control system pressure sensor.

3.

Turn ignition switch ON and check output voltage between ECM

terminal 32 and ground under the following conditions.

CAUTION:

• Always calibrate the vacuum pump gauge when using it.

• Never apply below -93.3 kPa (-0.952 kg/cm

2

, -13.53 psi ) or

pressure over 101.3 kPa (1.033 kg/cm

2

, 14.69 inHg).

4.

If NG, replace EVAP control system pressure sensor.

Applied vacuum kPa

(kg/cm

2

, psi)

Voltage (V)

Not applied

1.8 - 4.8

-26.7 (-200, -7.87)

2.1 to 2.5V lower than above value

PBIB1200E