Nissan Frontier D40. Manual - part 84

BRC-34

< COMPONENT DIAGNOSIS >

[TYPE 1]

C1111 ABS MOTOR, MOTOR RELAY SYSTEM

C1111 ABS MOTOR, MOTOR RELAY SYSTEM

Description

INFOID:0000000005275062

PUMP

The pump returns the brake fluid stored in the reservoir to the master cylinder by reducing the pressure.

MOTOR

The motor drives the pump according to the signals transmitted by the ABS actuator and electric unit (control

unit).

DTC Logic

INFOID:0000000005275063

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

CHECK SELF-DIAGNOSIS RESULTS

Check the self-diagnosis results.

Is above displayed on the self-diagnosis display?

YES

>> Proceed to diagnosis procedure. Refer to

.

NO

>> Inspection End

Diagnosis Procedure

INFOID:0000000005275064

Regarding Wiring Diagram information, refer to

BRC-51, "Wiring Diagram - BRAKE CONTROL SYSTEM -

.

1.

CONNECTOR INSPECTION

1.

Turn ignition switch OFF.

2.

Disconnect ABS actuator and electric unit (control unit) connector.

3.

Check terminals for deformation, disconnect, looseness, and so on. If any malfunction is found, repair or

replace terminals.

4.

Reconnect connectors and then perform the self-diagnosis. Refer to

.

Is any item indicated on the self-diagnosis display?

YES

>> GO TO 2

NO

>> Poor connection of connector terminals. Repair or replace connector.

2.

CHECK ABS MOTOR AND MOTOR RELAY POWER SUPPLY CIRCUIT

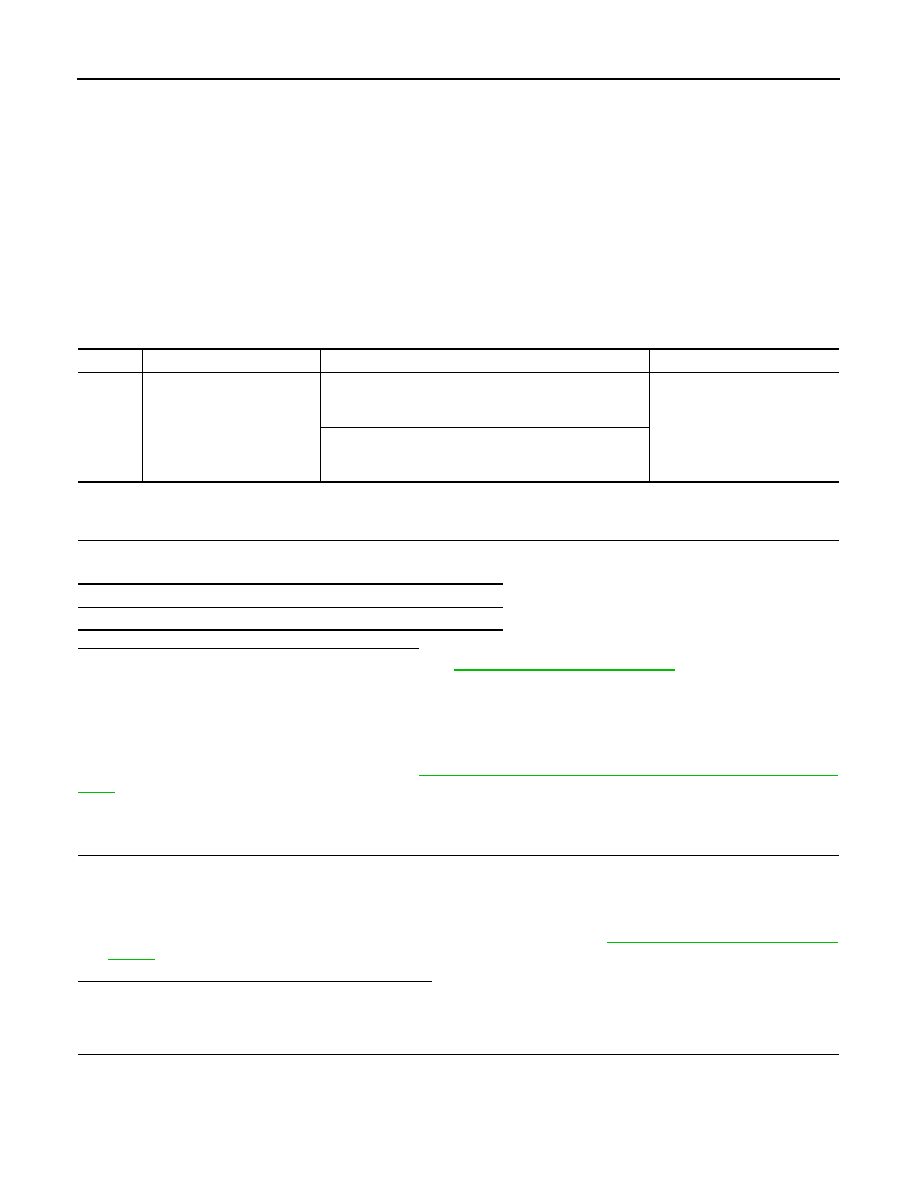

DTC

Display item

Malfunction detected condition

Possible cause

C1111

PUMP MOTOR

During the actuator motor operating with ON, when the

actuator motor turns OFF, or when the control line for ac-

tuator motor relay is open.

• Harness or connector

• ABS actuator and electric unit

(control unit)

During the actuator motor operating with OFF, when the

actuator motor turns ON, or when the control line for relay

is shorted to ground.

Self-diagnosis results

PUMP MOTOR