Nissan Terrano r20e. Manual - part 20

DIAGNOSTIC PROCEDURE

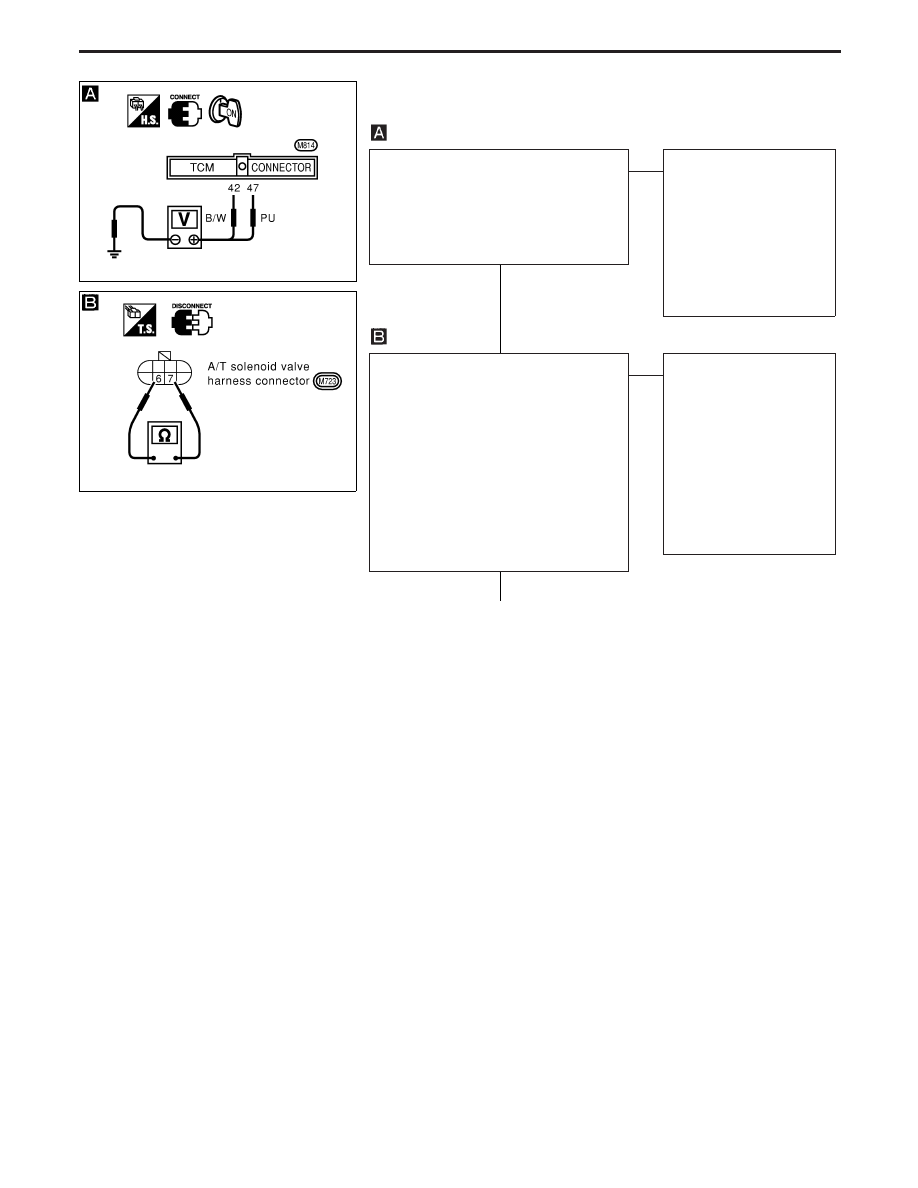

CHECK TCM POWER SOURCE.

1. Turn ignition switch to “ON” position.

(Do not start engine.)

2. Check voltage between TCM terminals

q

42

,

q

47

and ground.

Battery voltage should exist.

OK

E

NG

Check the following items:

I

Harness for short or

open between ignition

switch and TCM (Main

harness)

I

Ignition switch and fuse

Refer to EL section

(“POWER SUPPLY

ROUTING”).

CHECK A/T FLUID TEMPERATURE

SENSOR WITH TERMINAL CORD

ASSEMBLY.

1. Turn ignition switch to “OFF” position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminals

q

6

and

q

7

when A/T is cold.

Resistance:

Cold [20°C (68°F)]

Approximately 2.5 k

Ω

4. Reinstall any part removed.

OK

E

NG

1. Remove oil pan.

2. Check the following

items:

I

A/T fluid temperature

sensor

Refer to “COMPONENT

INSPECTION” on next

page.

I

Harness of terminal cord

assembly for short or

open

q

A

(Go to next page.)

YAT316

YAT317

H

H

TROUBLE DIAGNOSIS FOR BATT/FLUID TEMP SEN

A/T Fluid Temperature Sensor and TCM Power

Source (Cont’d)

AT-77