Nissan Titan. Manual - part 364

PRECAUTIONS

HA-7

< PRECAUTION >

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

CAUTION:

The new and former refrigerant connections use different O-ring configurations. Do not confuse O-

rings since they are not interchangeable. If a wrong O-ring is installed, refrigerant will leak at or

around the connection.

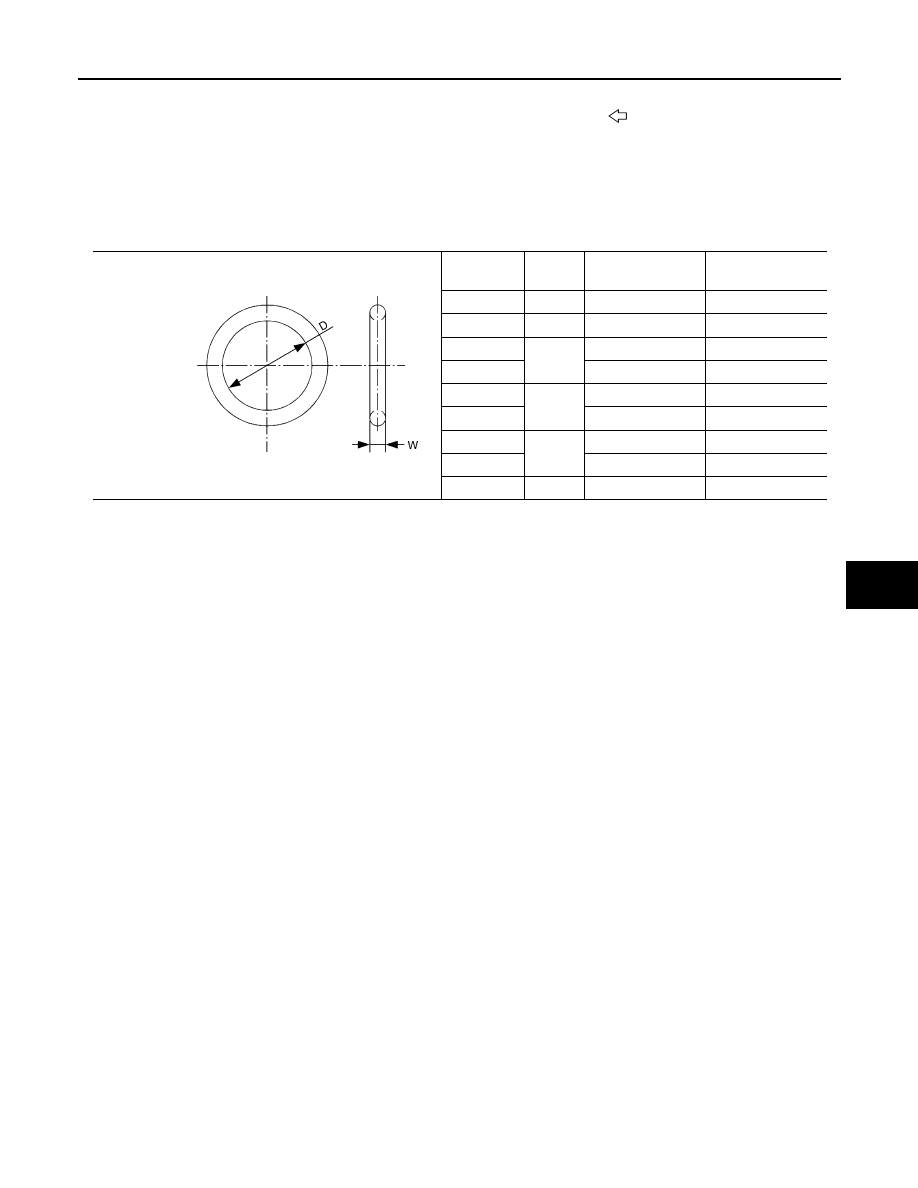

O-Ring Part Specifications*

*: Always check with the Parts Department for the latest parts information.

WARNING:

Make sure all refrigerant is discharged into the recycling equipment and the pressure in the system is

less than atmospheric pressure. Then gradually loosen the discharge side hose fitting and remove it.

CAUTION:

When replacing or cleaning refrigerant cycle components, observe the following.

• When the compressor is removed, store it in the same position as it is when mounted on the car.

Failure to do so will cause oil to enter the low pressure chamber.

• When connecting tubes, always use a torque wrench and a back-up wrench.

• After disconnecting tubes, immediately plug all openings to prevent entry of dirt and moisture.

• When installing an air conditioner in the vehicle, connect the pipes as the final stage of the opera-

tion. Do not remove the seal caps of pipes and other components until just before required for con-

nection.

• Allow components stored in cool areas to warm to working area temperature before removing seal

caps. This prevents condensation from forming inside A/C components.

• Thoroughly remove moisture from the refrigeration system before charging the refrigerant.

• Always replace used O-rings.

• When connecting tube, apply oil to circle of the O-rings shown in illustration. Be careful not to apply

oil to threaded portion.

Oil name: NISSAN A/C System Oil Type S or equivalent

• O-ring must be closely attached to dented portion of tube.

• When replacing the O-ring, be careful not to damage O-ring and tube.

• Connect tube until you hear it click, then tighten the nut or bolt by hand until snug. Make sure that

the O-ring is installed to tube correctly.

• After connecting line, conduct leak test and make sure that there is no leakage from connections.

When the gas leaking point is found, disconnect that line and replace the O-ring. Then tighten con-

nections of seal seat to the specified torque.

16.

Low-pressure flexible hose

17.

High-pressure flexible hose

18. Low-pressure service valve

19.

Low-pressure pipe

20.

Drain hose

Front

Connection

type

O-ring

size

D mm (in)

W mm (in)

New

8

6.8 (0.268)

1.85 (0.0728)

Former

10

9.25 (0.3642)

1.78 (0.0701)

New

12

10.9 (0.429)

2.43 (0.0957)

Former

11.0 (0.433)

2.4 (0.094)

New

16

13.6 (0.535)

2.43 (0.0957)

Former

14.3 (0.563)

2.3 (0.091)

New

19

16.5 (0.650)

2.43 (0.0957)

Former

17.12 (0.6740)

1.78 (0.0701)

New

24

21.8 (0.858)

2.4 (0.094)

SHA814E