Nissan Titan. Manual - part 324

EM-100

< UNIT DISASSEMBLY AND ASSEMBLY >

ENGINE UNIT

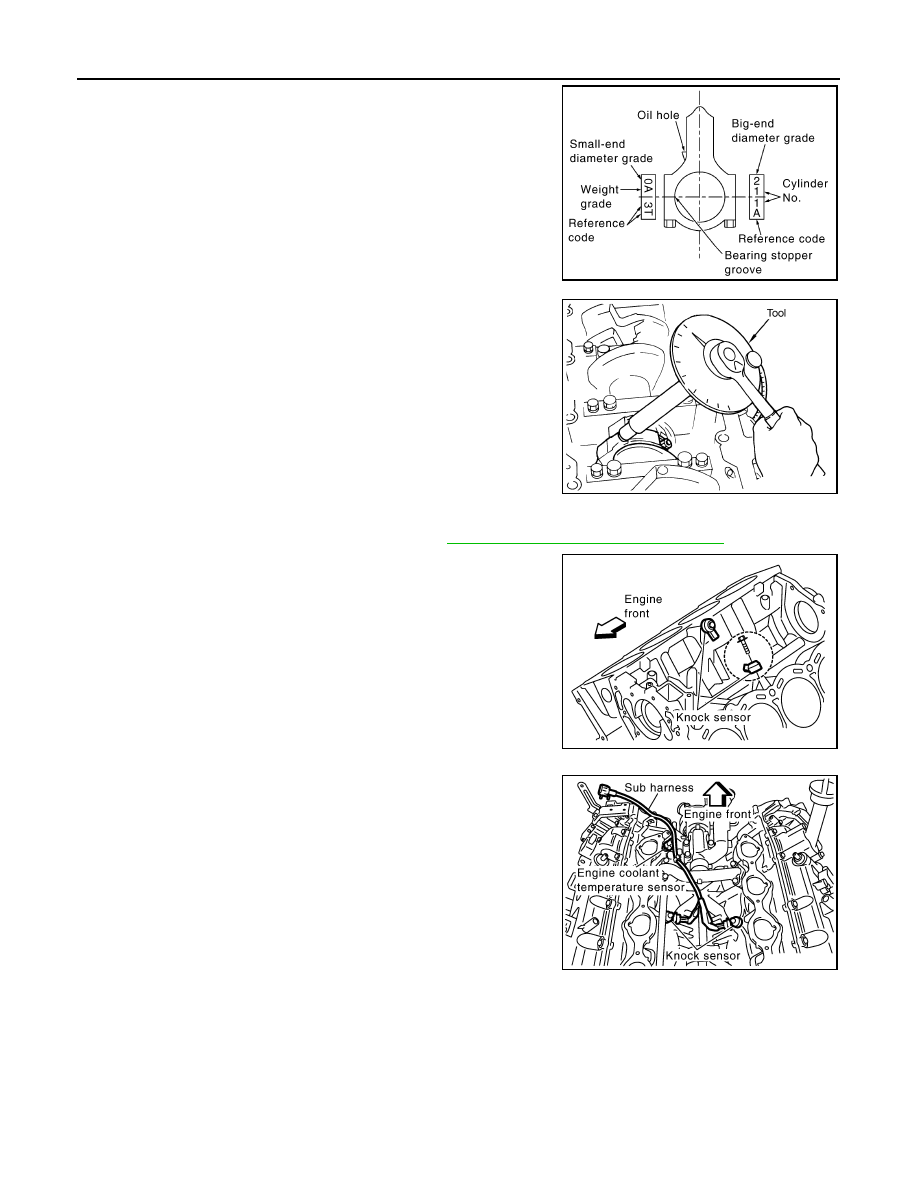

14. Install connecting rod cap.

• Match the stamped cylinder number marks on the connecting

rod with those on the cylinder cap to install.

15. Tighten connecting rod bolts using Tool.

• Apply engine oil to threads and seats of connecting rod bolts.

• After tightening bolts, make sure the crankshaft rotates smoothly.

• Check connecting rod side clearance. Refer to

EM-101, "Inspection After Disassembly"

.

16. Install knock sensors.

CAUTION:

If knock sensor is dropped, replace it with a new one.

• Make sure that there is no foreign material on the cylinder

block mating surface and the back surface of knock sensor.

• Install it with its connector facing the center of the cylinder

block side.

• Do not tighten knock sensor bolts while holding connector.

• Make sure knock sensor does not interfere with other parts.

• Position the sub-harness as shown before installing intake

manifold.

17. Installation of the remaining components is in the reverse order of removal.

18. Remove engine assembly from engine stand.

KBIA2536E

Tool number

: KV10112100 (BT-8653-A)

Connecting rod bolts

Step 1

: 29.4 N·m (3.0 kg-m, 22 ft-lb)

Step 2

: Loosen to 0 N·m

Step 3

: 19.6 N·m (1.5 kg-m, 11 ft-lb)

Step 4

: 90

° clockwise

WBIA0627E

KBIA2493E

KBIA2549E