Nissan Titan. Manual - part 281

P2096, P2097, P2098, P2099 A/F SENSOR 1

EC-425

< DTC/CIRCUIT DIAGNOSIS >

[VK56DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

2. Turn ignition switch OFF.

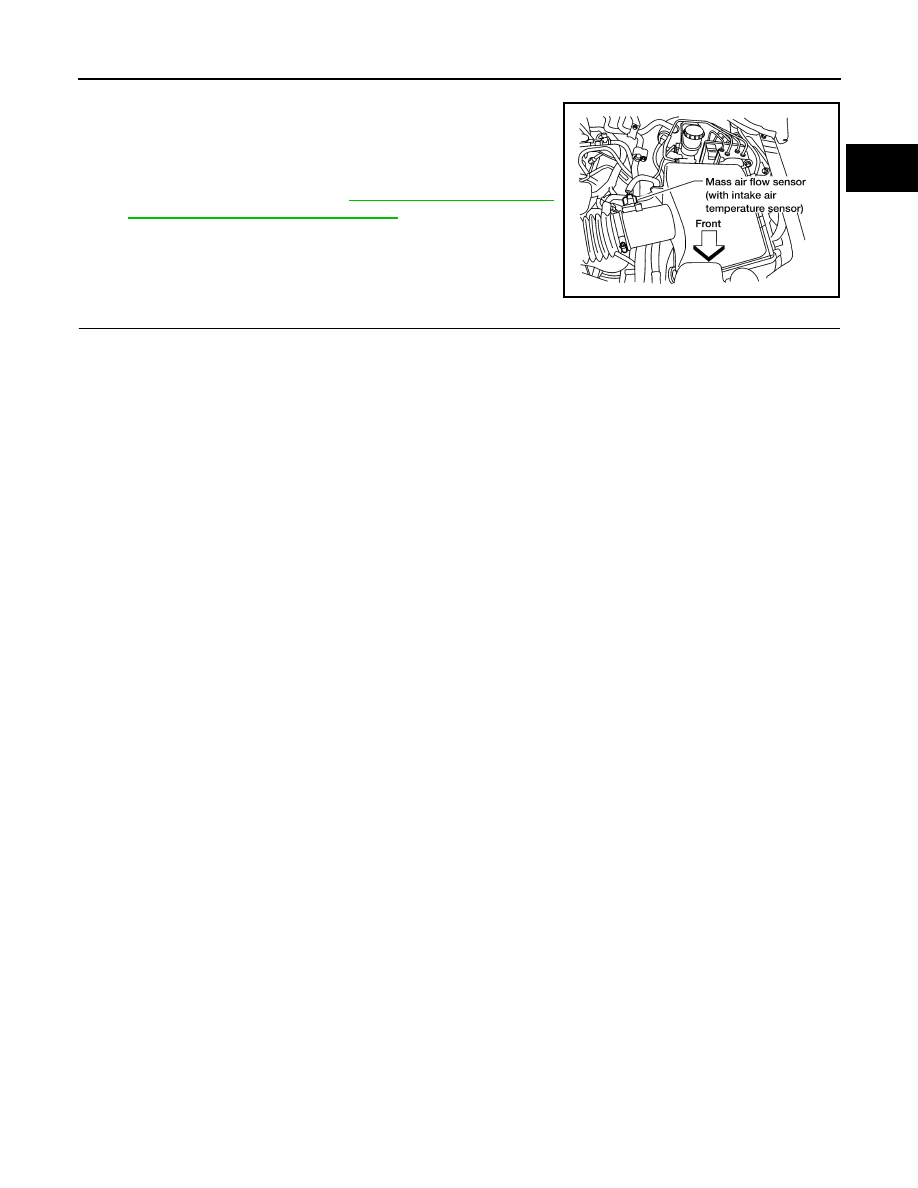

3. Disconnect mass air flow sensor harness connector.

4. Restart engine and let it idle for at least 5 seconds.

5. Stop engine and reconnect mass air flow sensor harness con-

nector.

6. Make sure DTC P0102 is displayed.

7. Erase the DTC memory. Refer to

EC-46, "On Board Diagnosis Function"

8. Make sure DTC P0000 is displayed.

>> GO TO 16.

16.

CONFIRM A/F ADJUSTMENT DATA

1. Turn ignition switch OFF and then ON.

2. Select “A/F ADJ-B1” and “A/F ADJ-B2” in “DATA MONITOR” mode with CONSULT.

3. Make sure that “0.000” is displayed on CONSULT screen.

>> INSPECTION END

BBIA0368E