Nissan Titan. Manual - part 242

P0327, P0328, P0332, P0333 KS

EC-269

< DTC/CIRCUIT DIAGNOSIS >

[VK56DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P0327, P0328, P0332, P0333 KS

Component Description

INFOID:0000000009886673

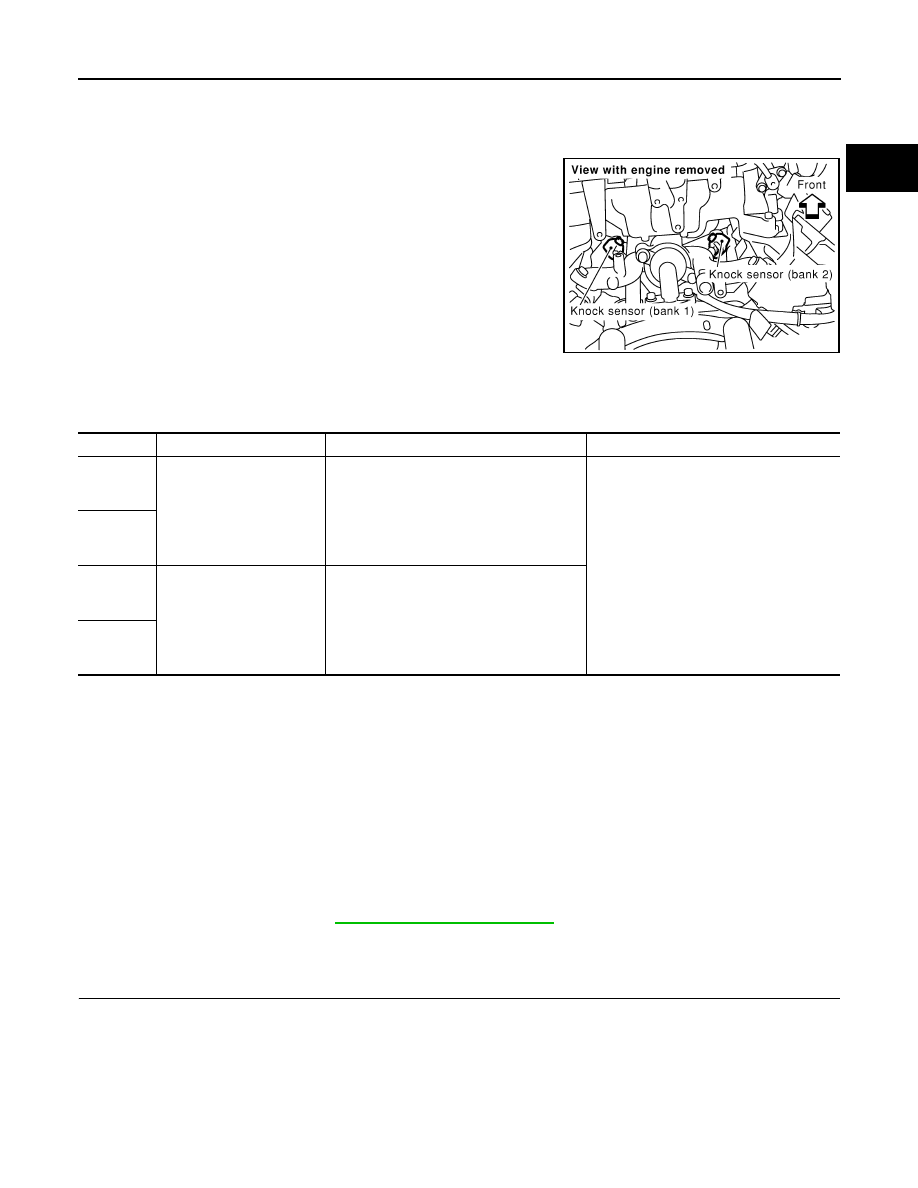

The knock sensor is attached to the cylinder block. It senses engine

knocking using a piezoelectric element. A knocking vibration from

the cylinder block is sensed as vibrational pressure. This pressure is

converted into a voltage signal and sent to the ECM.

On Board Diagnosis Logic

INFOID:0000000009886674

The MIL will not light up for these self-diagnoses.

DTC Confirmation Procedure

INFOID:0000000009886675

NOTE:

If DTC Confirmation Procedure has been previously conducted, always perform the following before conduct-

ing the next step.

1. Turn ignition swich OFF and wait at least 10 seconds.

2. Turn ignition swich ON.

3. Turn ignition swich OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10V at idle.

1. Start engine and run it for at least 5 seconds at idle speed.

2. Check 1st trip DTC.

3. If 1st trip DTC is detected, go to

Diagnosis Procedure

INFOID:0000000009886676

1.

CHECK KNOCK SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT-I

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check resistance between ECM terminals 15, 36 and ground. Refer to Wiring Diagram.

NOTE:

It is necessary to use an ohmmeter which can measure more than 10 M

Ω.

PBIB0021E

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P0327

0327

(bank 1)

Knock sensor circuit low in-

put

An excessively low voltage from the sensor

is sent to ECM.

• Harness or connectors

(The sensor circuit is open or shorted.)

• Knock sensor

P0332

0332

(bank 2)

P0328

0328

(bank 1)

Knock sensor circuit high in-

put

An excessively high voltage from the sensor

is sent to ECM.

P0333

0333

(bank 2)

Resistance: Approximately 532 - 588 k

Ω [at 20°C (68°F)]