Nissan Titan. Manual - part 229

P0133, P0153 A/F SENSOR 1

EC-217

< DTC/CIRCUIT DIAGNOSIS >

[VK56DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

OK or NG

OK

>> GO TO 2.

NG

>> Repair or replace ground connections.

2.

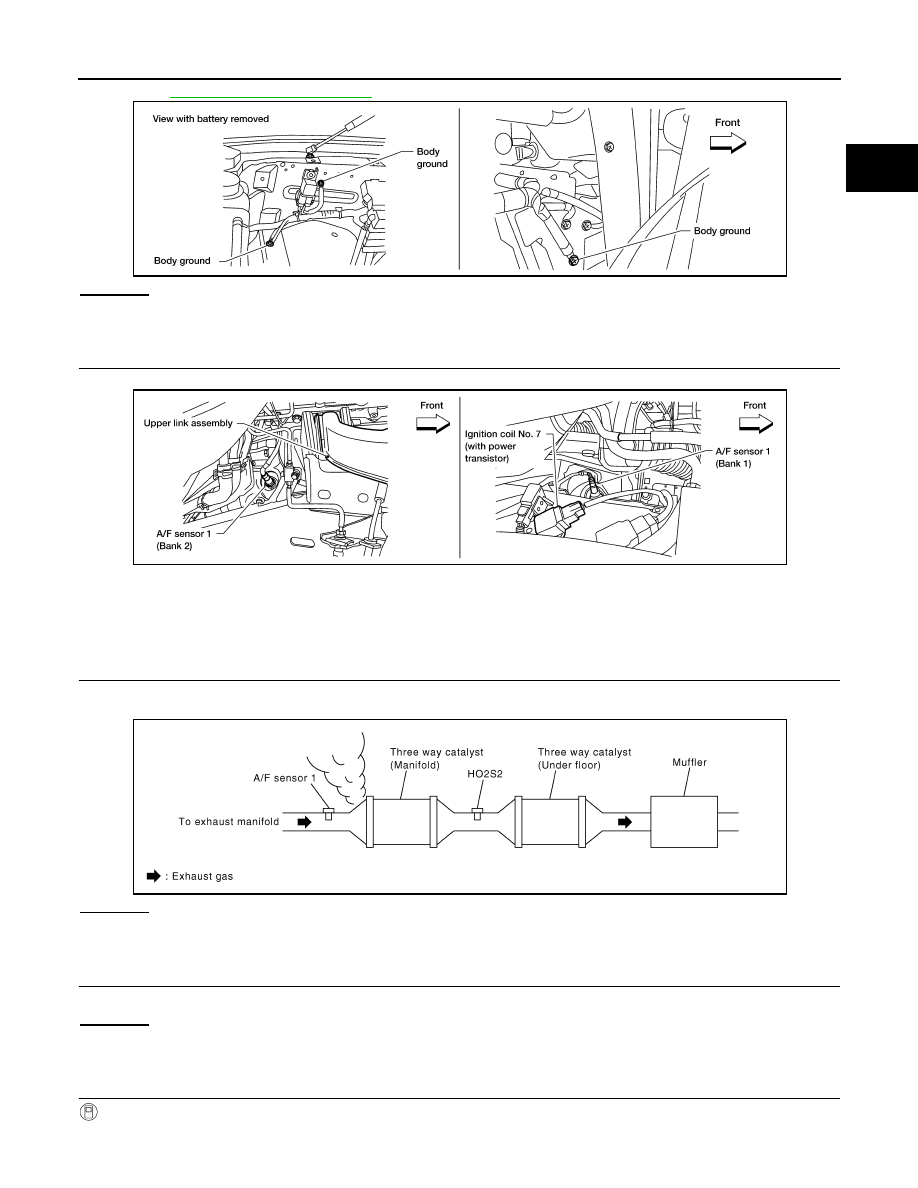

RETIGHTEN A/F SENSOR 1

Loosen and retighten the A/F sensor 1.

>> GO TO 3.

3.

CHECK EXHAUST GAS LEAK

1. Start engine and run it at idle.

2. Listen for an exhaust gas leak before three way catalyst (manifold).

OK or NG

OK

>> GO TO 4.

NG

>> Repair or replace.

4.

CHECK FOR INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

OK or NG

OK

>> GO TO 5.

NG

>> Repair or replace.

5.

CLEAR THE SELF-LEARNING DATA

With CONSULT

1. Start engine and warm it up to normal operating temperature.

BBIA0354E

Tightening torque: 50 N-m (5.1 kg-m, 37 ft-lb)

BBIA0375E

PBIB1216E