Nissan Titan. Manual - part 28

C1130, C1131, C1132, C1133, C1136 ENGINE SIGNAL

BRC-53

< DTC/CIRCUIT DIAGNOSIS >

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

C1130, C1131, C1132, C1133, C1136 ENGINE SIGNAL

Description

INFOID:0000000009883650

ABS actuator and electric unit (control unit) and ECM exchange the engine signal with CAN communication

line.

DTC Logic

INFOID:0000000009883651

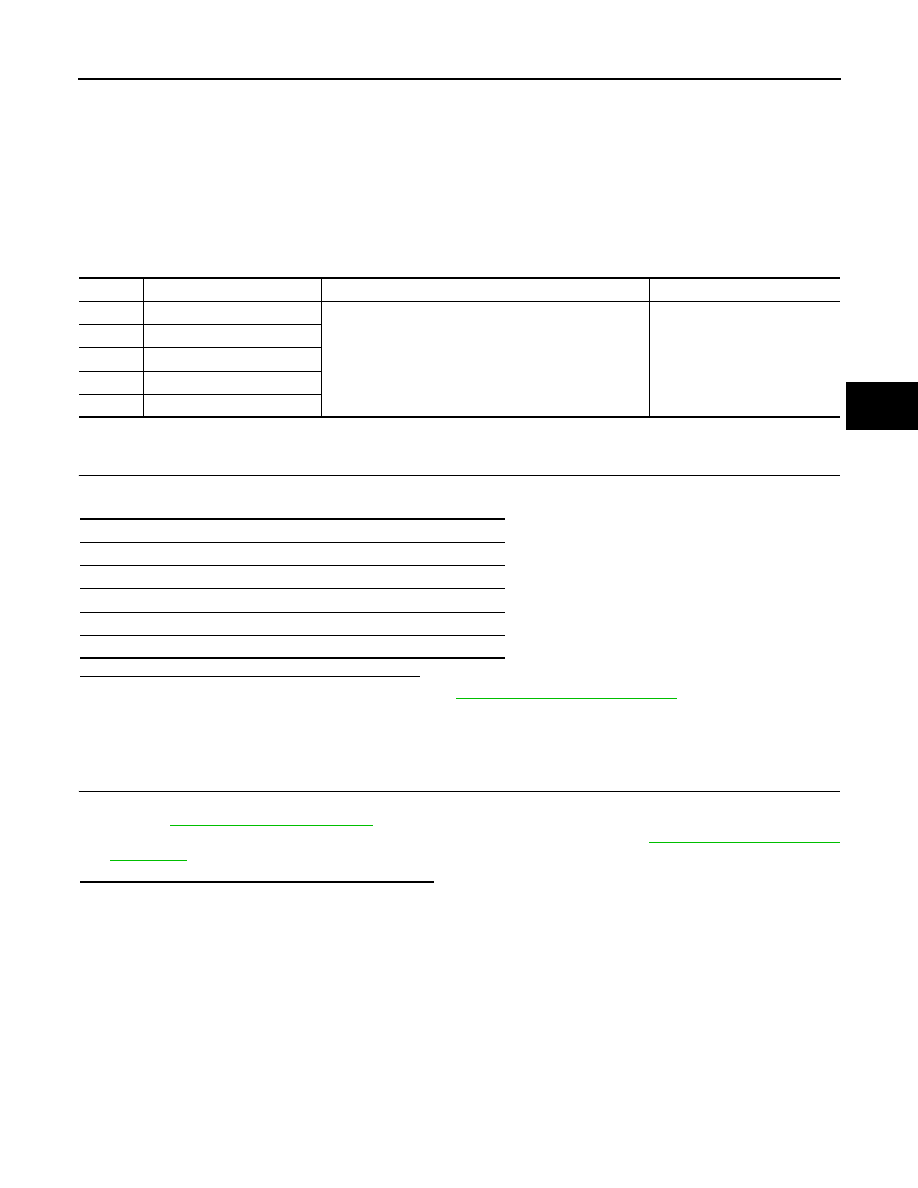

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

CHECK SELF-DIAGNOSIS RESULTS

Check the self-diagnosis results.

Is above displayed on the self-diagnosis display?

YES

>> Proceed to diagnosis procedure. Refer to

.

NO

>> Inspection End

Diagnosis Procedure

INFOID:0000000009883652

1.

CHECK ENGINE SYSTEM

1. Perform ECM self-diagnosis. Repair or replace items indicated, then perform ECM self-diagnosis again.

2. Perform ABS actuator and electric unit (control unit) self-diagnosis. Refer to

.

Is any item indicated on the self-diagnosis display?

YES

>> Repair or replace the affected part.

NO

>> Inspection End

DTC

Display item

Malfunction detected condition

Possible cause

C1130

ENGINE SIGNAL 1

Based on the signal from ECM, ABS actuator and electric

unit (control unit) judges that engine fuel cut system is

malfunctioning.

• Harness or connector

• ABS actuator and electric unit

(control unit)

• ECM

• CAN communication line

C1131

ENGINE SIGNAL 2

C1132

ENGINE SIGNAL 3

C1133

ENGINE SIGNAL 4

C1136

ENGINE SIGNAL 6

Self-diagnosis results

ENGINE SIGNAL 1

ENGINE SIGNAL 2

ENGINE SIGNAL 3

ENGINE SIGNAL 4

ENGINE SIGNAL 6