Nissan Titan. Manual - part 25

C1113, C1145, C1146 YAW RATE/SIDE/DECEL G SENSOR

BRC-41

< DTC/CIRCUIT DIAGNOSIS >

[VDC/TCS/ABS]

C

D

E

G

H

I

J

K

L

M

A

B

BRC

N

O

P

Is the inspection result normal?

YES

>> GO TO 3

NO

>> Repair or replace as necessary.

3.

YAW RATE/SIDE/DECEL G SENSOR INSPECTION

1. Connect the yaw rate/side/decel G sensor and ABS actuator and electric unit (control unit) connectors.

2. Perform the yaw rate/side/decel G sensor component inspection. Refer to

Is the inspection result normal?

YES

>> Replace the ABS actuator and electric unit (control unit). Refer to

.

NO

>> Replace the yaw rate/side/decel G sensor and perform calibration of decel G-sensor. Refer to

BRC-119, "Removal and Installation"

.

Component Inspection

INFOID:0000000009883629

1.

CHECK DATA MONITOR

Select “YAW RATE SEN”, “SIDE G-SENSOR”, “DECEL G-SEN” in “DATA MONITOR” and check yaw rate/

side/decel G sensor signal.

Is the inspection result normal?

YES

>> Inspection End

NO

>> Go to diagnosis procedure. Refer to

Special Repair Requirement

INFOID:0000000009883630

1.

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

Always perform neutral position adjustment for the steering angle sensor when replacing the ABS actuator

and electric unit (control unit). Refer to

BRC-8, "ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL

.

>> GO TO 2

2.

CALIBRATION OF DECEL G SENSOR

Always perform calibration of decel G sensor when replacing the ABS actuator and electric unit (control unit).

BRC-9, "CALIBRATION OF DECEL G SENSOR : Description"

>> END

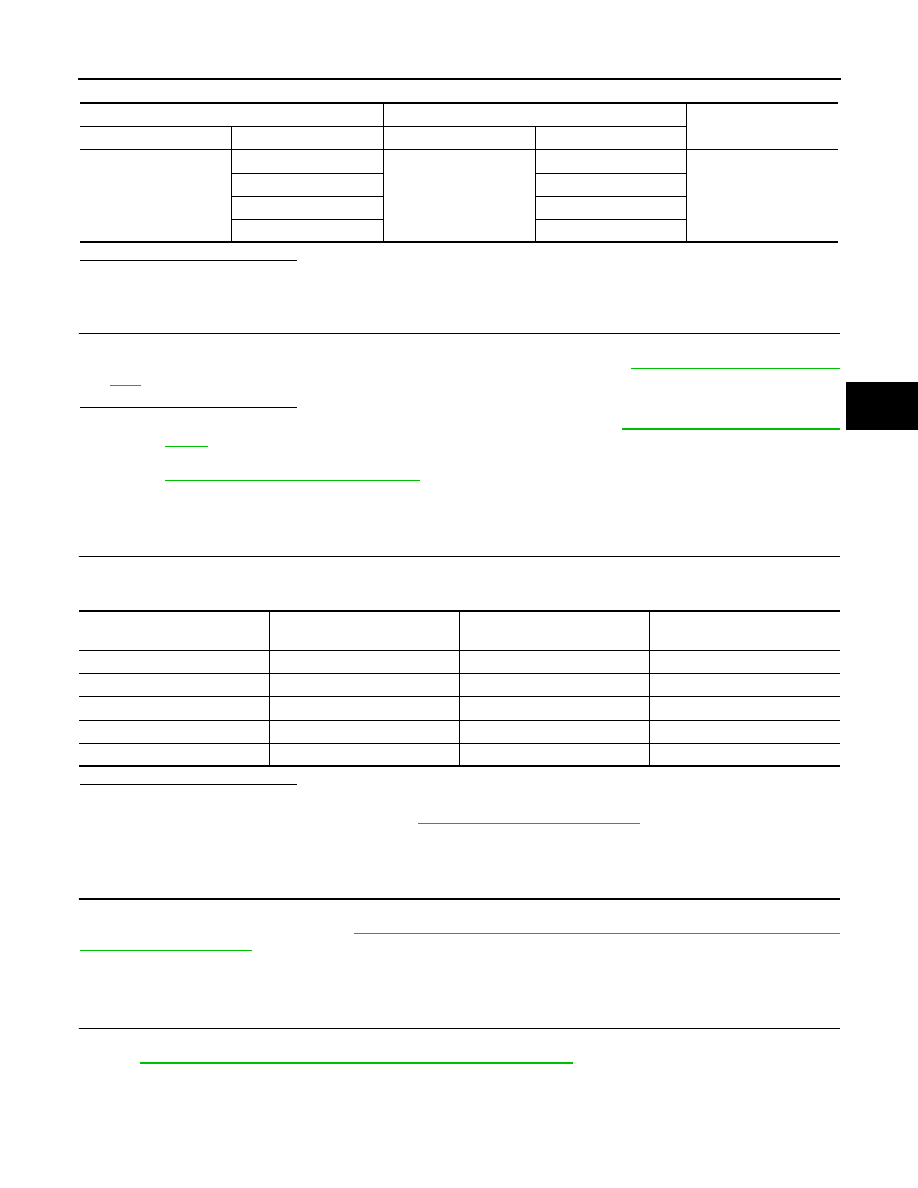

ABS actuator and electric unit (control unit)

Yaw rate/side/decel G sensor

Continuity

Connector

Terminal

Connector

Terminal

E125

6

M108

4

Yes

24

1

25

2

29

3

Vehicle condition

YAW RATE SEN

(DATA MONITOR)

SIDE G-SENSOR

(DATA MONITOR)

DECEL G-SEN

(DATA MONITOR)

Stopped

-4 to +4 deg/s

-1.1 to +1.1 m/s

-0.11 G to +0.11 G

Turning right

Negative value

Negative value

-

Turning left

Positive value

Positive value

-

Speed up

-

-

Negative value

Speed down

-

-

Positive value