Nissan Titan A60. Manual - part 716

MA-44

< PERIODIC MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

Check the caliper for leaks, repair as necessary.

PAD

Check the pads for wear or damage. Refer to

(front disc pad) ,

BR-7, "BRAKE PAD : Inspection"

disc pad) .

STEERING GEAR AND LINKAGE

STEERING GEAR AND LINKAGE : Checking Steering Gear and Linkage

INFOID:0000000006158446

STEERING GEAR

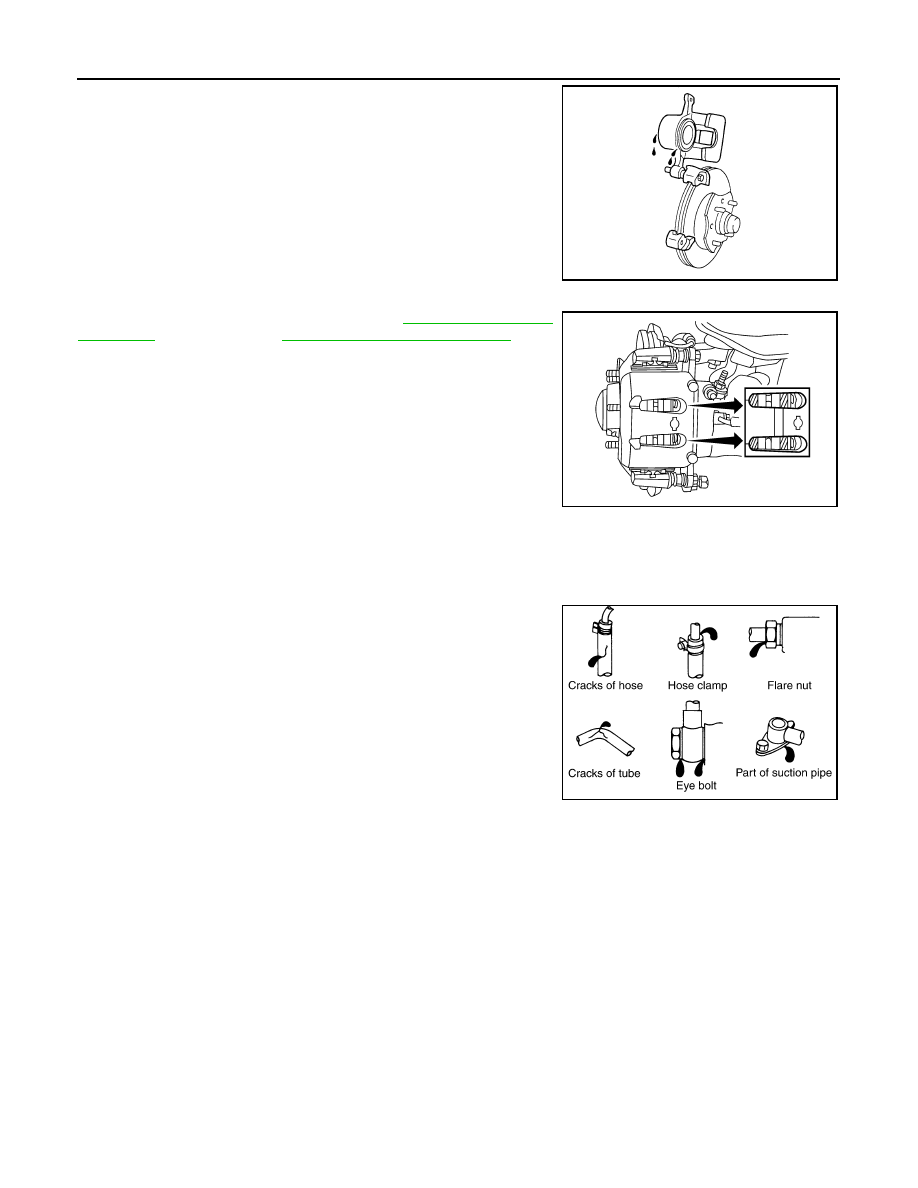

• Check the steering gear housing for looseness, damage, and oil

leakage as shown.

• Check the steering column connections for looseness.

STEERING LINKAGE

• Check the ball joint, dust cover and other component parts for looseness, wear, damage, and grease leak-

age.

POWER STEERING FLUID AND LINES

POWER STEERING FLUID AND LINES : Checking Power Steering Fluid and Line

INFOID:0000000006158447

CHECKING FLUID LEVEL

SMA922A

LMA051

SGIA0506E