Nissan Titan A60. Manual - part 459

CAMSHAFT VALVE CLEARANCE

EM-21

< PERIODIC MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

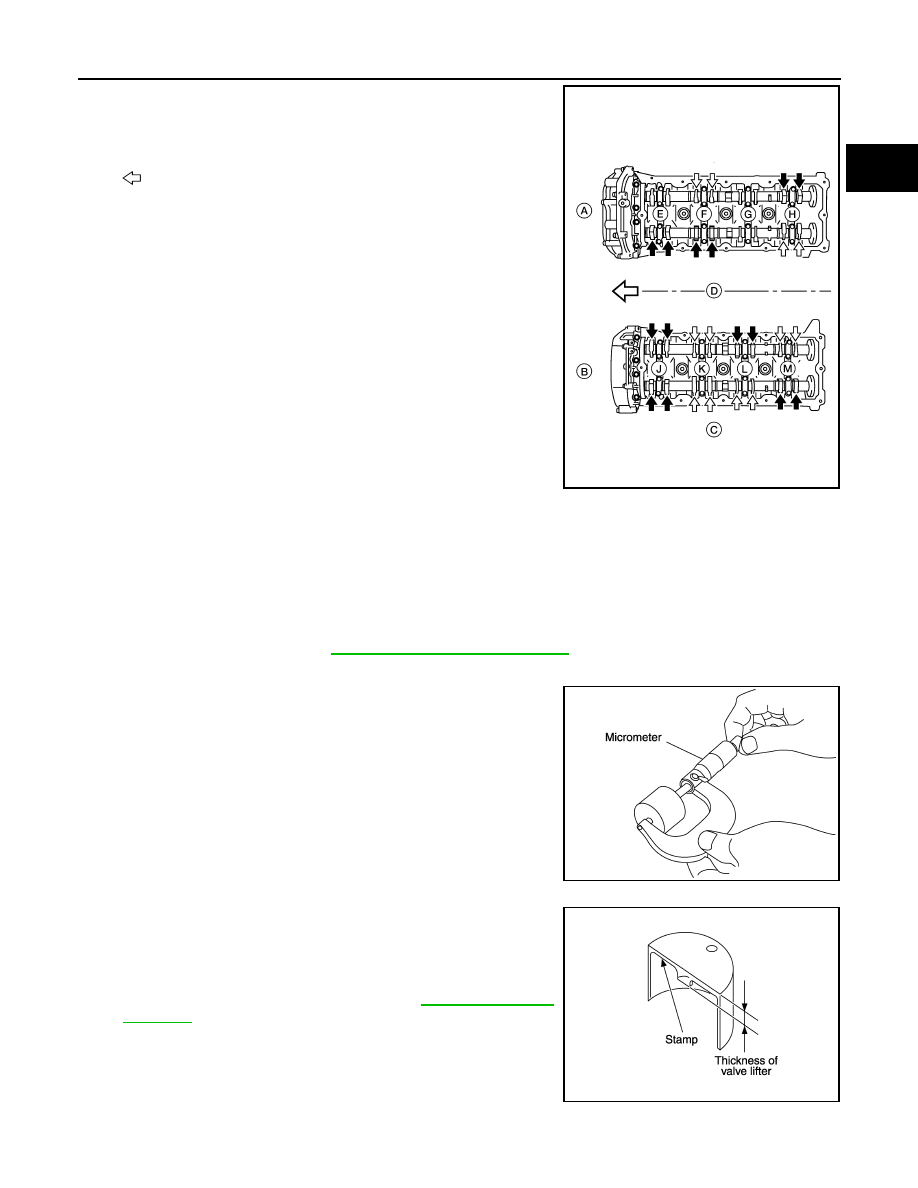

9. Turn the crankshaft pulley clockwise 90

° from the position of No.

3 cylinder compression TDC (clockwise by 360

° from the posi-

tion of No. 1 cylinder compression TDC) to measure the intake

and exhaust valve clearances of No. 6 cylinder (G) and the

exhaust valve clearance of No. 2 cylinder (E).

•

: Engine front

• A: RH

• B: LH

• C: Exhaust

• D: Intake

• E: No. 2 cylinder

• F: No. 4 cylinder

• G: No. 6 cylinder

• H: No. 8 cylinder

• J: No. 1 cylinder

• K: No. 3 cylinder

• L: No. 5 cylinder

• M: No. 7 cylinder

10. If out of specifications, adjust as necessary.

ADJUSTMENT

NOTE:

• Perform adjustment depending on the selected head thickness of the valve lifter.

• The specified valve lifter thickness is the dimension at normal temperatures. Ignore dimensional differences

caused by temperature. Use the specifications for hot engine condition to adjust.

1. Remove the camshaft. Refer to

EM-58, "Removal and Installation"

.

2. Remove the valve lifters at the locations that are out of specification.

3. Measure the center thickness of the removed valve lifters using

suitable tool.

4. Use the equation below to calculate the valve lifter thickness for

replacement.

• Valve lifter thickness calculation:

Thickness of replacement valve lifter = t1+ (C1 - C2)

t1 = Thickness of removed valve lifter

C1 = Measured valve clearance

C2= Standard valve clearance:

• Thickness of a new valve lifter can be identified by stamp

marks on the reverse side (inside the cylinder).

Stamp mark N788 indicates 7.88 mm (0.3102 in) in thickness.

• Available thickness of valve lifter: 25 sizes with range 7.88 to

8.36 mm (0.3102 to 0.3291 in) in steps of 0.02 mm (0.0008 in)

(when manufactured at factory). Refer to

5. Install the selected valve lifter.

WBIA0713E

KBIA0057E

KBIA0119E