Nissan Titan A60. Manual - part 407

EC-294

< DTC/CIRCUIT DIAGNOSIS >

[VK56DE]

P0448 EVAP CANISTER VENT CONTROL VALVE

8. If 1st trip DTC is detected, go to

If 1st trip DTC is not detected, go to the next step.

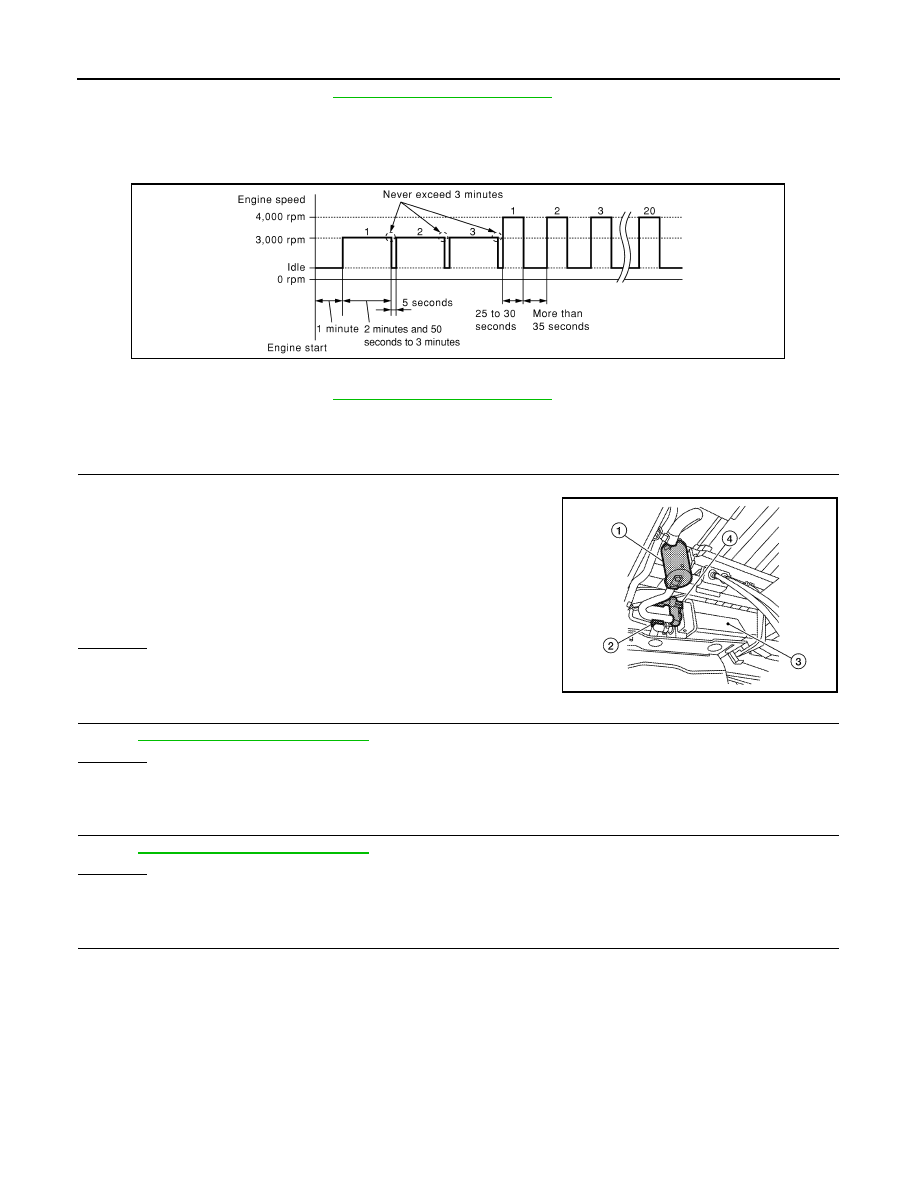

9. Repeat next procedure 20 times.

a. Quickly increase the engine speed up to 4,000 to 4,500 rpm or more and keep it for 25 to 30 seconds.

b. Fully released accelerator pedal and keep engine idle for at least 35 seconds.

10. Check 1st trip DTC.

11. If 1st trip DTC is detected, go to

Diagnosis Procedure

INFOID:0000000006158725

1.

CHECK RUBBER TUBE

1. Turn ignition switch OFF.

2. Disconnect rubber tube connected to EVAP canister vent control

valve (4).

3. Check the rubber tube for clogging.

OK or NG

OK

>> GO TO 2.

NG

>> Clean rubber tube using an air blower.

2.

CHECK DRAIN FILTER

EC-295, "Component Inspection"

OK or NG

OK

>> GO TO 3.

NG

>> Replace drain filter.

3.

CHECK EVAP CANISTER VENT CONTROL VALVE

EC-295, "Component Inspection"

OK or NG

OK

>> GO TO 4.

NG

>> Replace EVAP canister vent control valve.

4.

CHECK IF EVAP CANISTER SATURATED WITH WATER

1. Remove EVAP canister with EVAP canister vent control valve and EVAP control system pressure sensor

attached.

PBIB0972E

1

: Drain filter

2

: EVAP control system pressure sensor

3

: EVAP canister

ALBIA0401ZZ