Nissan Titan A60. Manual - part 381

EC-190

< DTC/CIRCUIT DIAGNOSIS >

[VK56DE]

P0128 THERMOSTAT FUNCTION

Component Inspection

INFOID:0000000006158618

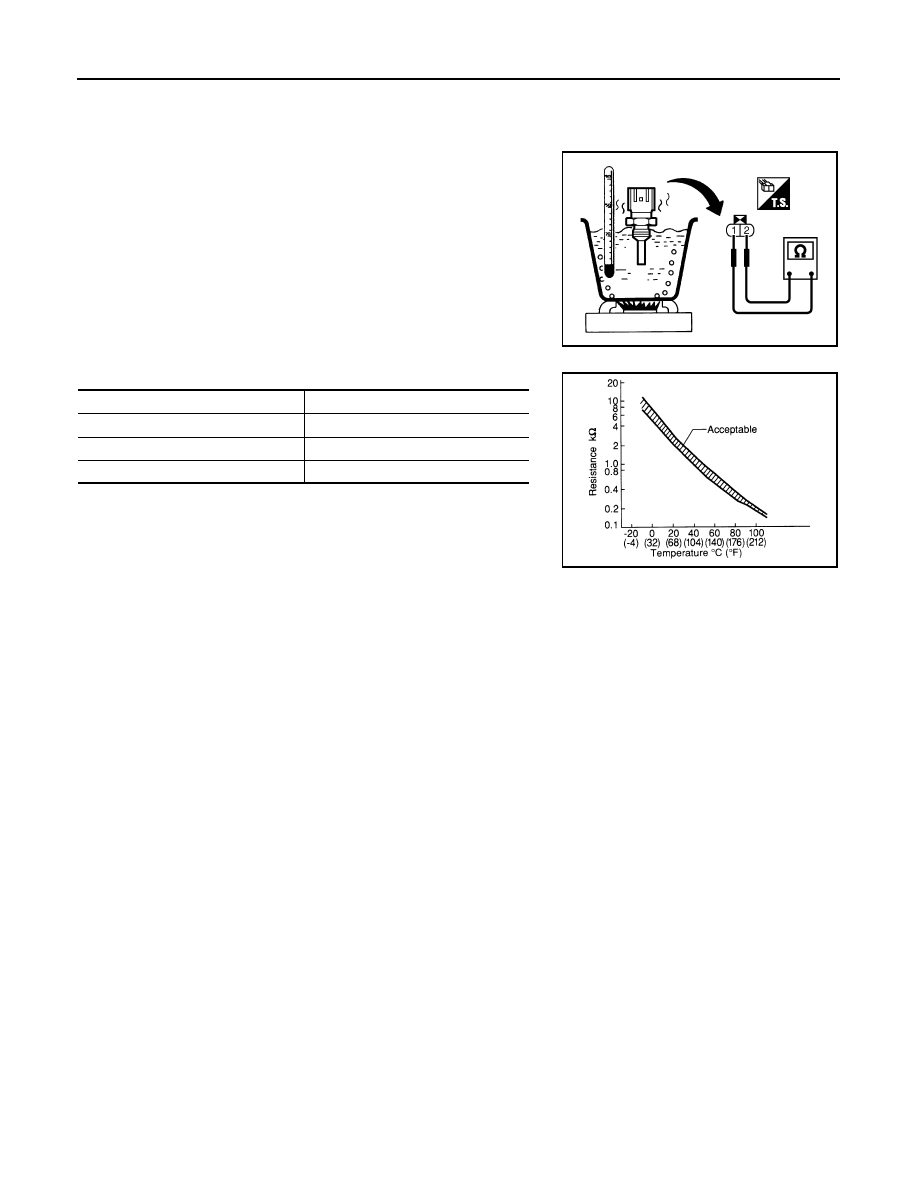

ENGINE COOLANT TEMPERATURE SENSOR

1. Check resistance between engine coolant temperature sensor

terminals 1 and 2 as shown in the figure.

2. If NG, replace engine coolant temperature sensor.

PBIB2005E

Engine coolant temperature

°C (°F)]

Resistance (k

Ω)

20 (68)

2.1 - 2.9

50 (122)

0.68 - 1.00

90 (194)

0.236 - 0.260

SEF012P