Nissan Titan A60. Manual - part 369

EC-142

< DTC/CIRCUIT DIAGNOSIS >

[VK56DE]

P0011, P0021 IVT CONTROL

P0011, P0021 IVT CONTROL

On Board Diagnosis Logic

INFOID:0000000006158555

FAIL-SAFE MODE

When the malfunction is detected, the ECM enters fail-safe mode.

DTC Confirmation Procedure

INFOID:0000000006158556

CAUTION:

Always drive at a safe speed.

NOTE:

• If DTC P0011 or P0021 is displayed with DTC P0075, P0081, P1140 or P1145, first perform the trouble

diagnosis for

or

• If DTC Confirmation Procedure has been previously conducted, always perform the following before con-

ducting the next step.

1. Turn ignition swich OFF and wait at least 10 seconds.

2. Turn ignition swich ON.

3. Turn ignition swich OFF and wait at least 10 seconds.

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is between 10V and 16V at

idle.

PROCEDURE FOR MALFUNCTION A

1. Turn ignition switch ON.

2. Select “DATA MONITOR” mode with CONSULT-III.

3. Maintain the following conditions for at least 10 consecutive seconds.

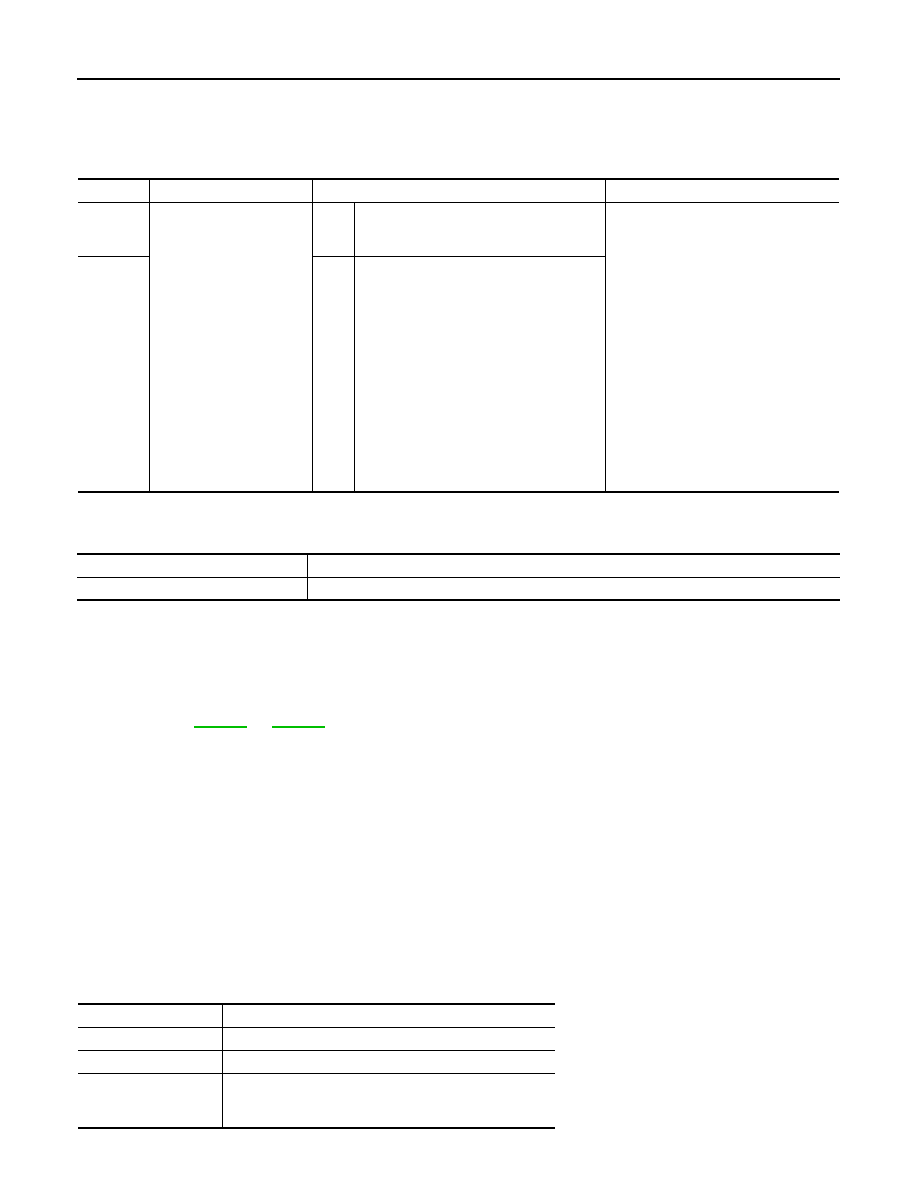

DTC No.

Trouble diagnosis name

Detecting condition

Possible cause

P0011

0011

(Bank 1)

Intake valve timing control

performance

A

The alignment of the intake valve timing

control has been misresistered.

• Harness or connectors

(Intake valve timing control solenoid

valve circuit is open or shorted.)

• Harness or connectors

(Intake valve timing control position

sensor circuit is open or shorted.)

• Intake valve timing control solenoid

valve

• Intake valve timing control position

sensor

• Crankshaft position sensor (POS)

• Camshaft position sensor (PHASE)

• Accumulation of debris to the signal

pick-up portion of the camshaft

sprocket

• Timing chain installation

• Foreign matter caught in the oil

groove for intake valve timing control

P0021

0021

(Bank 2)

B

There is a gap between angle of target and

phase-control angle degree.

Detected items

Engine operating condition in fail-safe mode

Intake valve timing control

The signal is not energized to the solenoid valve and the valve control does not function

ENG SPEED

More than 2,000 rpm (A constant rotation is maintained.)

COOLAN TEMP/S

More than 70

°C (158°F)

Selector lever

1st or 2nd position

Driving location uphill

Driving vehicle uphill

(Increased engine load will help maintain the driving con-

ditions required for this test.)