Nissan Titan A60. Manual - part 360

EC-106

< BASIC INSPECTION >

[VK56DE]

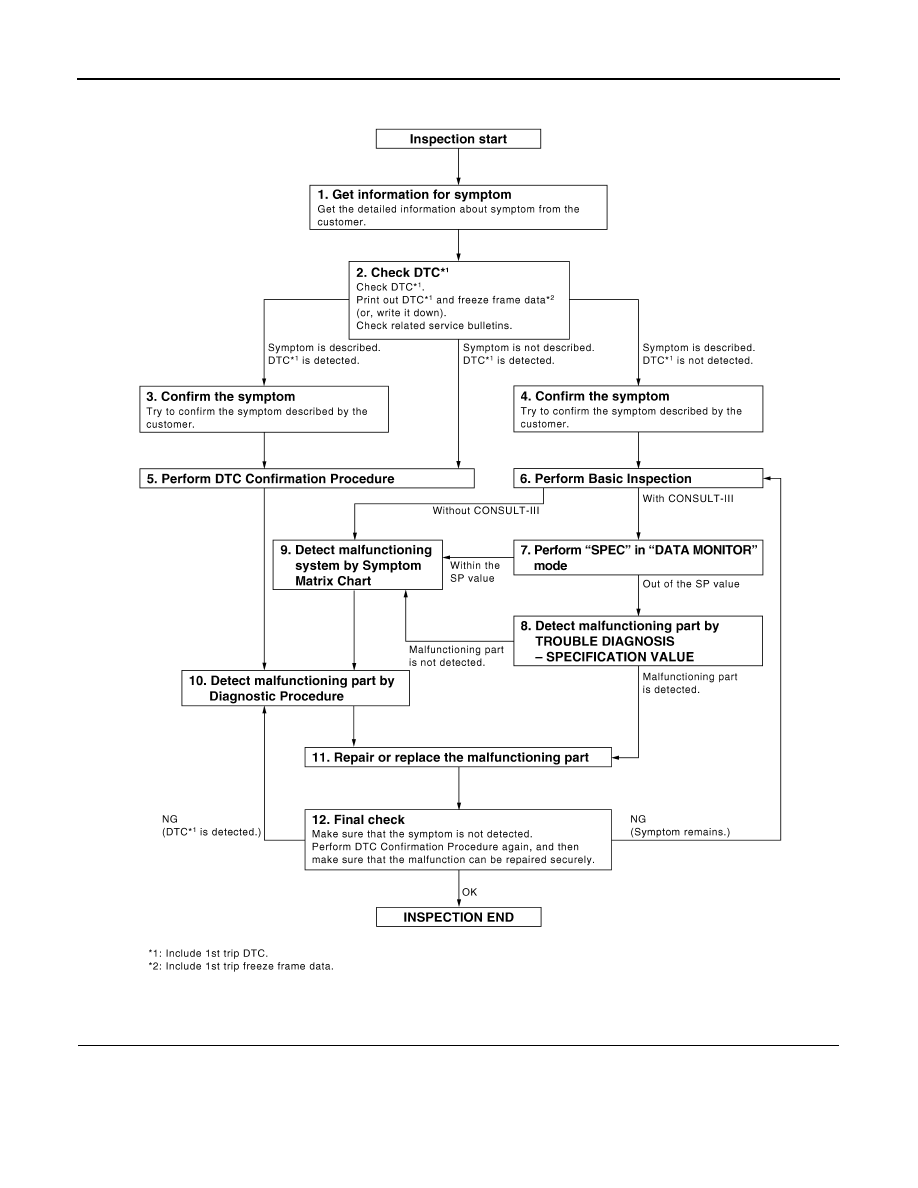

DIAGNOSIS AND REPAIR WORKFLOW

Overall Sequence

Detailed Flow

1.

GET INFORMATION FOR SYMPTOM

Get the detailed information from the customer about the symptom (the condition and the environment when

the incident/malfunction occurred) using the "DIAGNOSTIC WORKSHEET" .

>> GO TO 2.

PBIB3456E