Nissan Titan A60. Manual - part 301

PROPELLER SHAFT

DLN-143

< UNIT DISASSEMBLY AND ASSEMBLY >

[PROPELLER SHAFT: 2S1410]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

UNIT DISASSEMBLY AND ASSEMBLY

PROPELLER SHAFT

Disassembly and Assembly

INFOID:0000000006179527

DISASSEMBLY

Journal

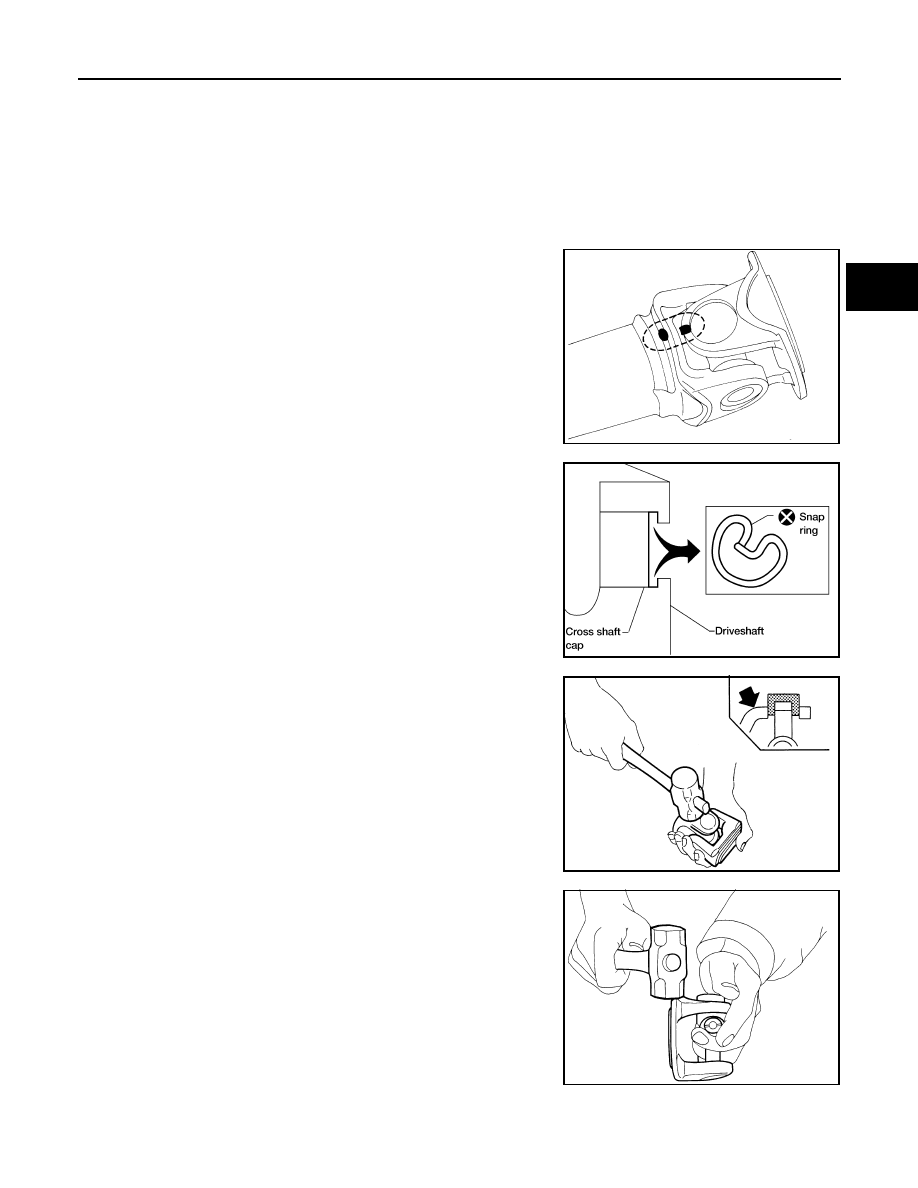

1. Put matching marks on the rear propeller shaft and flange yoke

as shown.

CAUTION:

For matching marks use paint. Never damage the rear pro-

peller shaft or flange yoke.

2. Remove the snap rings.

3. Push out and remove the journal bearings by lightly tapping the

flange yoke with a hammer, taking care not to damage the jour-

nal or flange yoke hole.

NOTE:

Put marks on the disassembled parts so that they can be rein-

stalled in their original positions from which they were removed.

4. Push out and remove the remaining journal bearings at the

opposite side by lightly tapping the flange yoke with a hammer,

taking care not to damage the journal or flange yoke hole.

NOTE:

Put marks on the disassembled parts so that they can be rein-

stalled in their original positions from which they were removed.

ASSEMBLY

SPD128

APD011

SPD732

SPD131