Nissan Titan A60. Manual - part 278

P1819 TRANSFER CONTROL DEVICE

DLN-51

< DTC/CIRCUIT DIAGNOSIS >

[TRANSFER: TX15B]

C

E

F

G

H

I

J

K

L

M

A

B

DLN

N

O

P

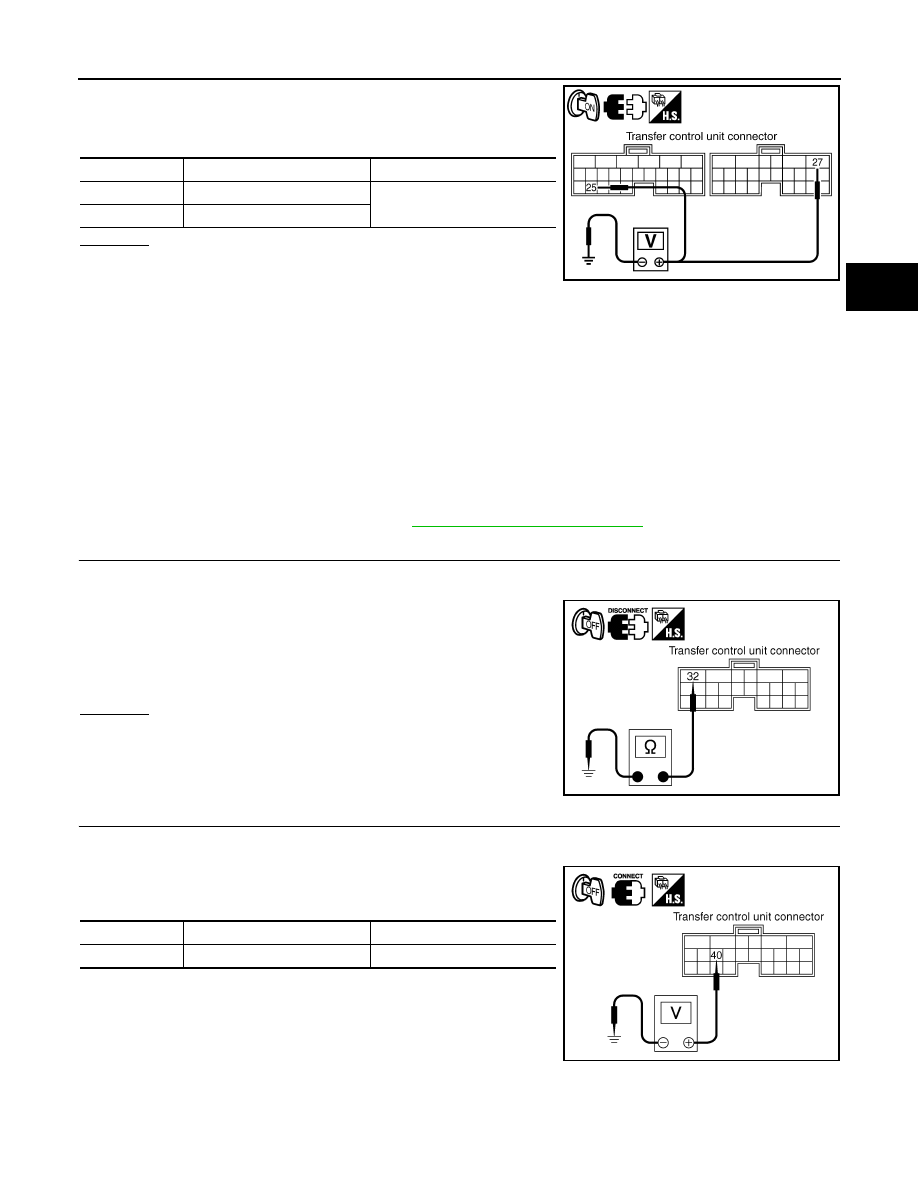

4. Turn ignition switch ON. (Do not start engine.)

5. Check voltage between transfer control unit harness connector

terminals and ground.

OK or NG

OK

>> GO TO 2.

NG

>> Check the following. If any items are damaged, repair

or replace damaged parts.

• 10A fuse (No. 59, located in the fuse and relay block).

• Harness for short or open between battery and transfer shut off relay 1 harness connector E46

terminal 5.

• Harness for short or open between transfer control unit harness connector E143 terminal 27 and

transfer shut off relay 1 harness connector E46 terminal 3.

• Harness for short or open between ignition switch and transfer shut off relay 1 harness connec-

tor E46 terminal 2.

• Harness for short or open between transfer shut off relay 1 harness connector E46 terminal 1

and ground.

• Harness for short or open between ignition switch and transfer control unit harness connector

E142 terminal 25.

• Battery and ignition switch.

• Transfer shut off relay 1. Refer to

DLN-22, "Component Inspection"

2.

CHECK GROUND CIRCUIT

1. Turn ignition switch OFF (stay for at least 5 seconds).

2. Disconnect transfer control unit harness connector.

3. Check continuity between transfer control unit harness connec-

tor E143 terminal 32 and ground.

Also check harness for short to power.

OK or NG

OK

>> GO TO 3.

NG

>> Repair open circuit or short to power in harness or con-

nectors.

3.

CHECK POWER SUPPLY SIGNAL

1. Turn ignition switch OFF. (Stay for at least 5 seconds.)

2. Connect transfer control unit harness connector.

3. Check voltage between transfer control unit harness connector

terminal and ground.

Connector

Terminal

Voltage (Approx.)

E142

25 - Ground

Battery voltage

E143

27 - Ground

SDIA3372E

Continuity should exist.

SDIA2818E

Connector

Terminal

Voltage (Approx.)

E143

40 - Ground

Battery voltage

SDIA2819E