Nissan Titan A60. Manual - part 155

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-47

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D

E

G

H

I

J

K

L

M

A

B

BR

N

O

P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specification

INFOID:0000000006163306

Unit: mm (in)

Brake Pedal

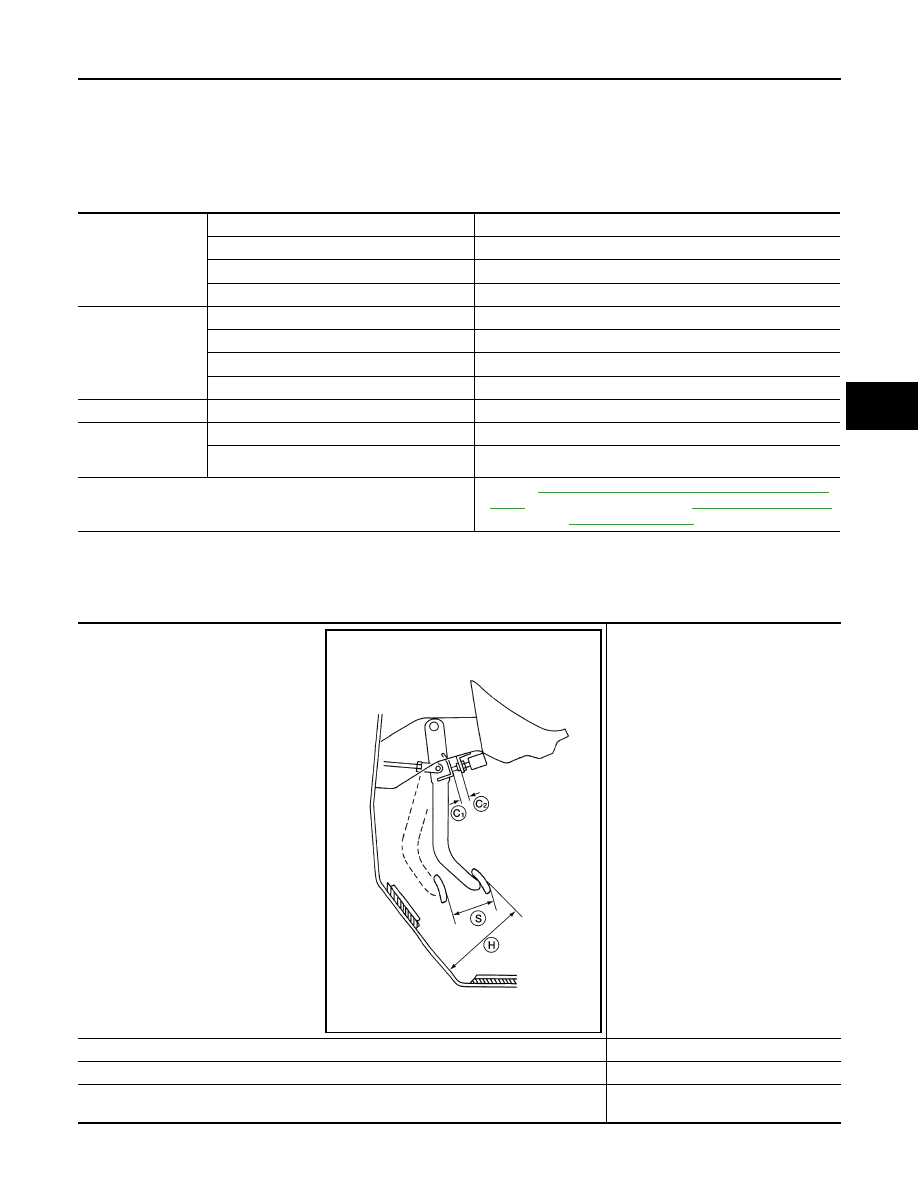

INFOID:0000000006163307

STANDARD PEDAL

Unit: mm (in)

Front brake

Brake model

AD41VA

Rotor outer diameter

× thickness

350

× 30 (13.78 × 1.181)

Pad Length

× width × thickness

151.6

× 56.5 × 12.0 (5.97 × 2.22 × 0.472)

Cylinder bore diameter (each)

50.8 (2.00)

Rear brake

Brake model

AD14VE

Rotor outer diameter

× thickness

320

× 14 (12.6 × 0.551)

Pad Length

× width × thickness

83.0

× 33.0 × 12.0 (3.268 × 1.299 × 0.472)

Cylinder bore diameter

48 (1.89)

Control valve

Valve model

Electric brake force distribution

Brake booster

Booster model

C215T

Diaphragm diameter

215 (8.46)

Recommended brake fluid

MA-21, "FOR NORTH AMERICA : Fluids and Lubri-

(Mexico).

Free height (H)

182.3

− 192.3 (7.18 − 7.57)

Pedal full stroke (S)

152.3 (6.00)

Clearance between brake pedal bracket and the threaded end of stop lamp switch (C1) and

ASCD cancel switch [if equipped] (C

2

)

0.74

− 1.96 (0.029 − 0.077)

AWFIA0557ZZ