Nissan Quest E52. Manual - part 774

HAC-226

< DTC/CIRCUIT DIAGNOSIS >

[MANUAL AIR CONDITIONING]

REAR BLOWER MOTOR

NOTE:

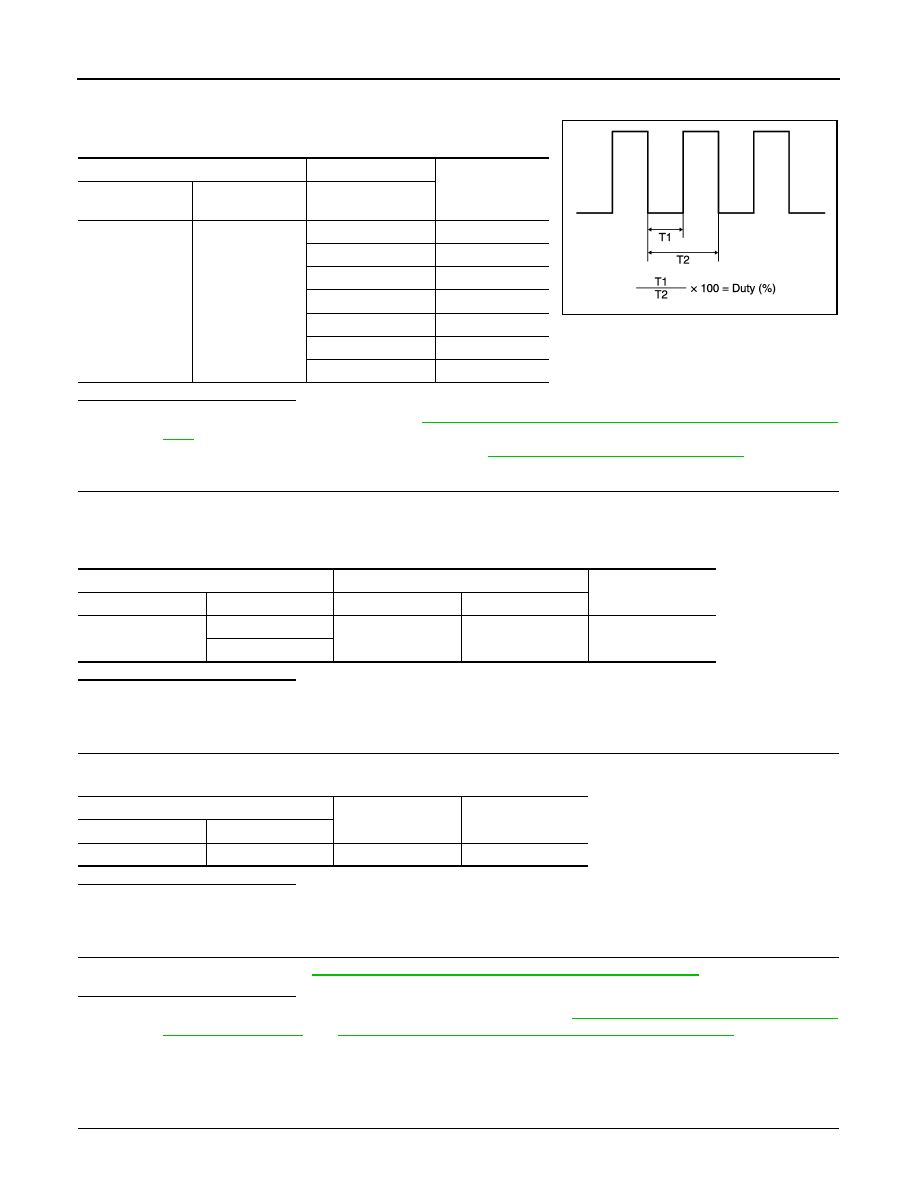

Calculate drive signal duty ratio as shown in the figure.

T2 = Approx. 1.6 ms

Is the inspection result normal?

YES

>> Replace rear blower motor. Refer to

VTL-18, "REAR BLOWER MOTOR : Removal and Installa-

.

NO

>> Replace front A/C control (A/C amp.). Refer to

HAC-238, "Removal and Installation"

.

6.

CHECK REAR BLOWER MOTOR POWER SUPPLY CIRCUIT FOR OPEN

1.

Turn ignition switch OFF.

2.

Disconnect rear blower relay connector.

3.

Check continuity between rear blower relay harness connector and rear blower motor harness connector.

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> Repair harness or connector.

7.

CHECK REAR BLOWER RELAY GROUND CIRCUIT FOR OPEN

Check continuity between rear blower relay harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> Repair harness or connector.

8.

CHECK REAR BLOWER RELAY

Check rear blower relay. Refer to

HAC-227, "Component Inspection (Rear Blower Relay)"

.

Is the inspection result normal?

YES

>> Check rear blower relay power supply circuit. Refer to

PG-11, "Wiring Diagram - BATTERY

PG-54, "Wiring Diagram - IGNITION POWER SUPPLY -"

NO

>> Replace rear blower relay.

Component Inspection (Rear Blower Motor)

INFOID:0000000009652666

1.

CHECK REAR BLOWER MOTOR-I

Rear blower motor

Condition

Duty ratio

(Approx.)

Connector

Terminal

Fan speed

VENT mode

B403

2

1st

25 %

2nd

33 %

3rd

41 %

4th

51 %

5th

61 %

6th

69 %

7th

81 %

JPLIA1210GB

Rear blower relay

Rear blower motor

Continuity

Connector

Terminal

Connector

Terminal

M14

5

B403

3

Existed

7

Rear blower relay

—

Continuity

Connector

Terminal

M14

2

Ground

Existed