Nissan Quest E52. Manual - part 750

HAC-130

< DTC/CIRCUIT DIAGNOSIS >

[AUTOMATIC AIR CONDITIONING]

REAR BLOWER MOTOR

1.

Remove rear blower motor. Refer to

VTL-18, "REAR BLOWER MOTOR : Removal and Installation"

2.

Check that there is not any mixing foreign object in the rear blower motor.

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Replace rear blower motor. Refer to

VTL-18, "REAR BLOWER MOTOR : Removal and Installa-

.

2.

CHECK REAR BLOWER MOTOR-II

Check that there is not breakage or damage in the rear blower motor.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Replace rear blower motor. Refer to

VTL-18, "REAR BLOWER MOTOR : Removal and Installa-

.

3.

CHECK REAR BLOWER MOTOR-III

Check that rear blower motor turns smoothly.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace rear blower motor. Refer to

VTL-18, "REAR BLOWER MOTOR : Removal and Installa-

.

Component Inspection (Rear Blower Relay)

INFOID:0000000009652577

1.

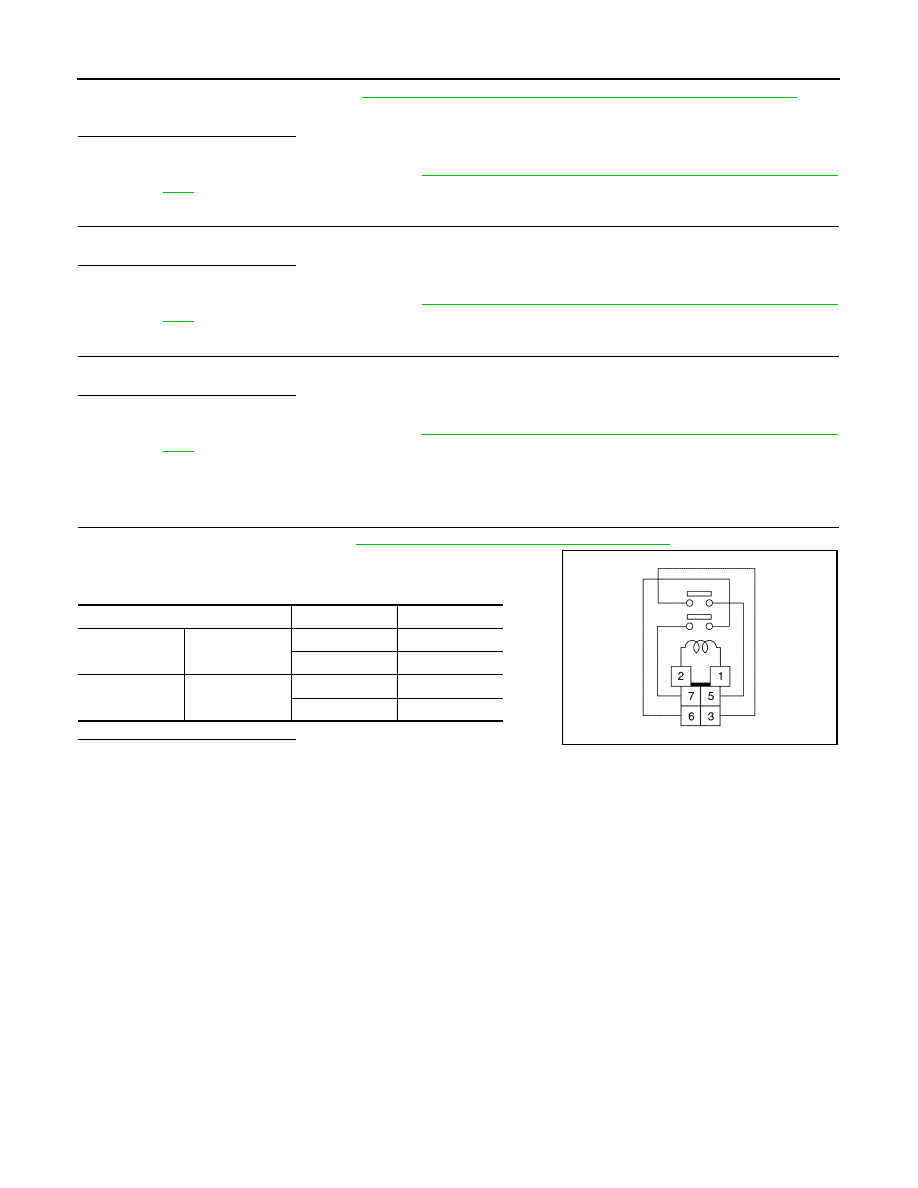

CHECK REAR BLOWER RELAY

1.

Remove rear blower relay. Refer to

PG-81, "Fuse and Fusible Link Arrangement"

2.

Check continuity between rear blower relay terminal 3 and 5,

then 6 and 7 when voltage is supplied between terminal 1 and 2.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace rear blower relay.

Terminal

Voltage

Continuity

3

5

ON

Existed

OFF

Not existed

6

7

ON

Existed

OFF

Not existed

JMIIA1869ZZ