Nissan Quest E52. Manual - part 581

TIMING CHAIN

EM-73

< UNIT DISASSEMBLY AND ASSEMBLY >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

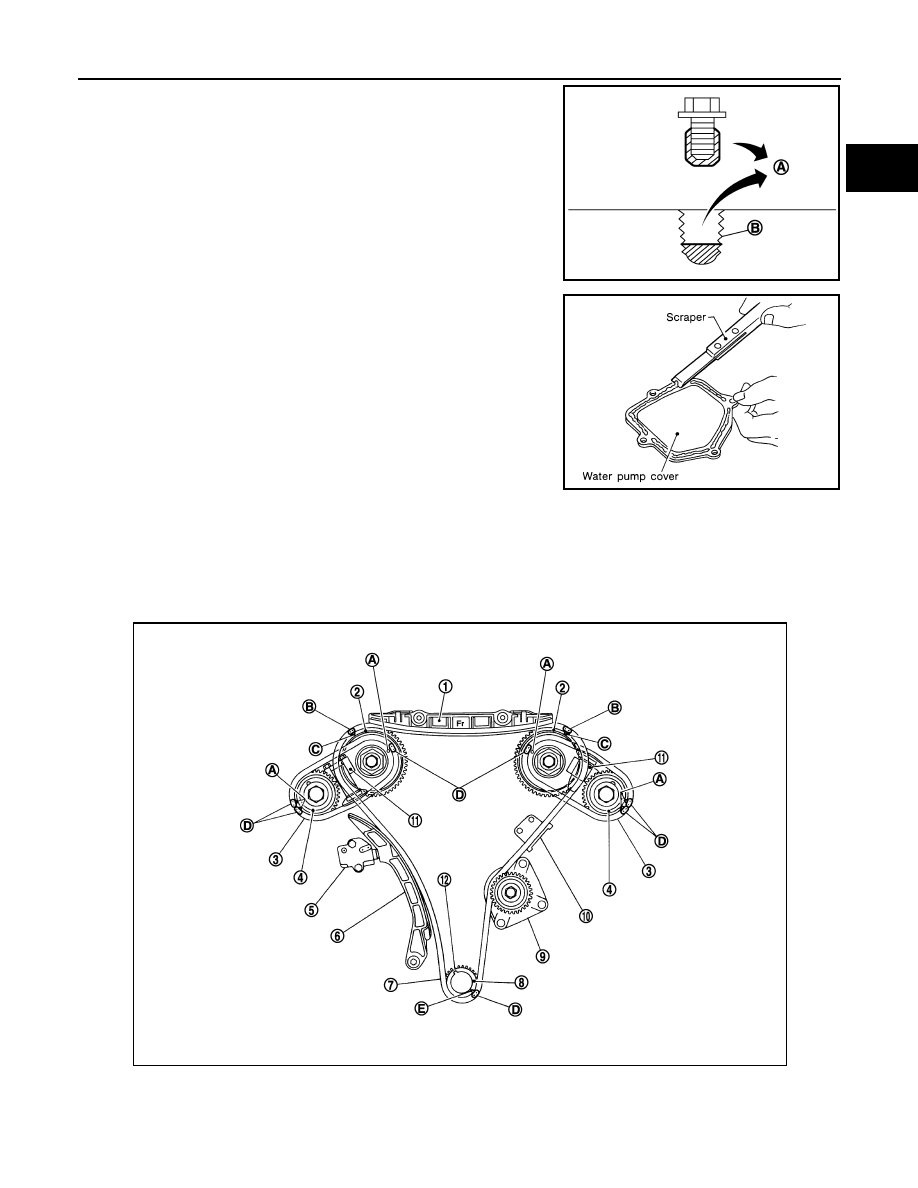

• Remove old liquid gasket from bolt hole (B) and thread.

21. Use a scraper to remove all traces of old liquid gasket from

water pump cover.

INSTALLATION

CAUTION:

Do not reuse O-rings.

NOTE:

The below figure shows the relationship between the mating mark on each timing chain and that on the corre-

sponding sprocket, with the components installed.

A

: Remove sticking old liquid gasket

JPBIA0051ZZ

SEM926E

1.

Internal chain guide

2.

Camshaft sprocket (INT)

3.

Timing chain (secondary)

4.

Camshaft sprocket (EXH)

5.

Timing chain tensioner (primary)

6.

Slack guide

7.

Timing chain (primary)

8.

Crankshaft sprocket

9.

Water pump

JPBIA1716GB