Nissan Quest E52. Manual - part 455

EC-30

< SYSTEM DESCRIPTION >

[VQ35DE]

STRUCTURE AND OPERATION

STRUCTURE AND OPERATION

Positive Crankcase Ventilation (PCV)

INFOID:0000000009650952

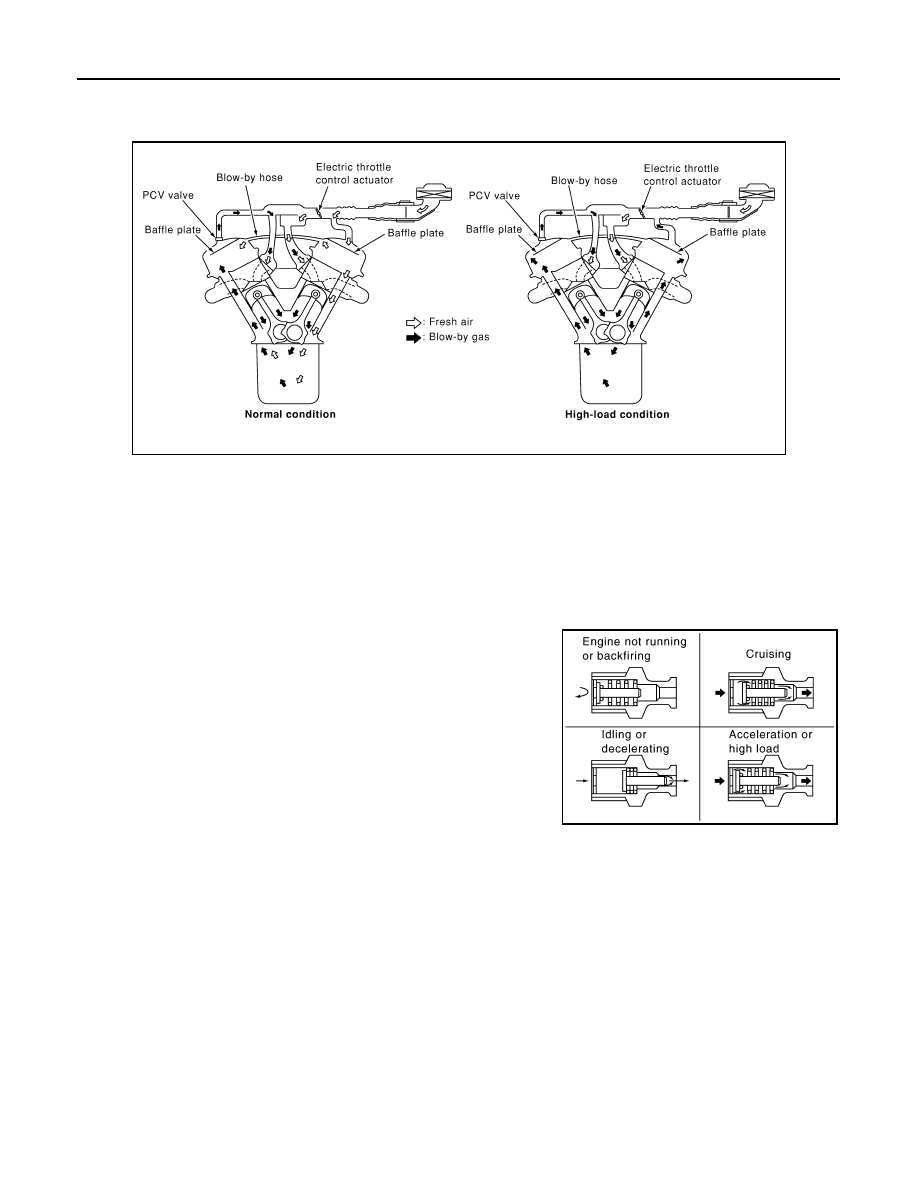

This system returns blow-by gas to the intake manifold.

The positive crankcase ventilation (PCV) valve is provided to conduct crankcase blow-by gas to the intake

manifold.

During partial throttle operation of the engine, the intake manifold sucks the blow-by gas through the PCV

valve.

Normally, the capacity of the valve is sufficient to handle any blow-by and a small amount of ventilating air.

The ventilating air is drawn from the air inlet tubes into the crankcase. In this process the air passes through

the hose connecting air inlet tubes to rocker cover.

Under full-throttle condition, the manifold vacuum is insufficient to draw the blow-by flow through the valve.

The flow goes through the hose connection in the reverse direction.

On vehicles with an excessively high blow-by, the valve does not

meet the requirement. This is because some of the flow will go

through the hose connection to the air inlet tubes under all condi-

tions.

SEC921C

PBIB1588E