Nissan Quest E52. Manual - part 289

CO-26

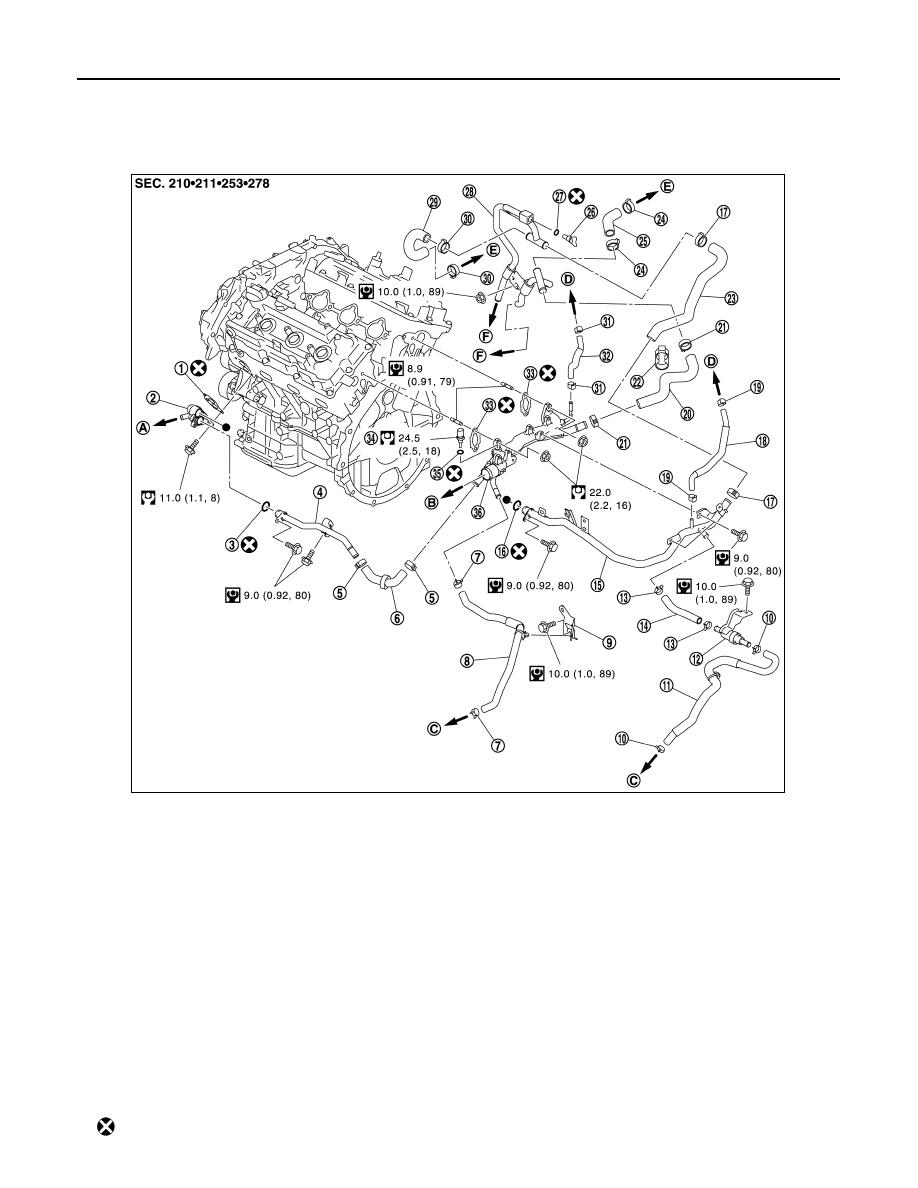

< REMOVAL AND INSTALLATION >

WATER OUTLET AND WATER PIPING

WATER OUTLET AND WATER PIPING

Exploded View

INFOID:0000000009650557

1.

Gasket

2.

Water connector

3.

O-ring

4.

Water bypass pipe

5.

Clamp

6.

Water hose

7.

Clamp

8.

Water hose

9.

Bracket

10. Clamp

11.

Water hose

12.

Heater thermostat

13. Clamp

14.

Water hose

15.

Heater pipe

16. O-ring

17.

Clamp

18.

Water hose

19. Clamp

20.

Heater hose

21.

Clamp

22. Clip

23.

Heater hose

24.

Clamp

25. Heater hose

26.

Air bleeder plug

27.

O-ring

28. Heater pipe

29.

Heater hose

30.

Clamp

31. Clamp

32.

Water hose

33.

Gasket

34. Engine coolant temperature sensor

35.

Gasket

36.

Water outlet

37. Bracket

A.

To oil cooler

B.

To radiator

C.

To CVT fluid warmer

D.

To electric throttle control actuator

E.

To heater core

F.

To rear heater

: Always replace after every disassembly.

JPBIA4661GB