Nissan Quest E52. Manual - part 224

BR-40

< REMOVAL AND INSTALLATION >

FRONT DISC BRAKE

7.

Perform inspection after installation. Refer to

BR-42, "BRAKE CALIPER ASSEMBLY : Inspection"

.

BRAKE CALIPER ASSEMBLY : Disassembly and Assembly

INFOID:0000000009651839

DISASSEMBLY

CAUTION:

Never drop the parts.

NOTE:

Never remove the torque member, brake pad, pad return spring and pad retainers when disassembling and

assembling the cylinder body.

1.

Remove the sliding pin bolt, and remove the cylinder body from the torque member. Refer to

"BRAKE PAD : Removal and Installation"

CAUTION:

Fix the brake pad at suitable tape so that the brake pad will not drop.

2.

Remove sliding pin boots from torque member.

3.

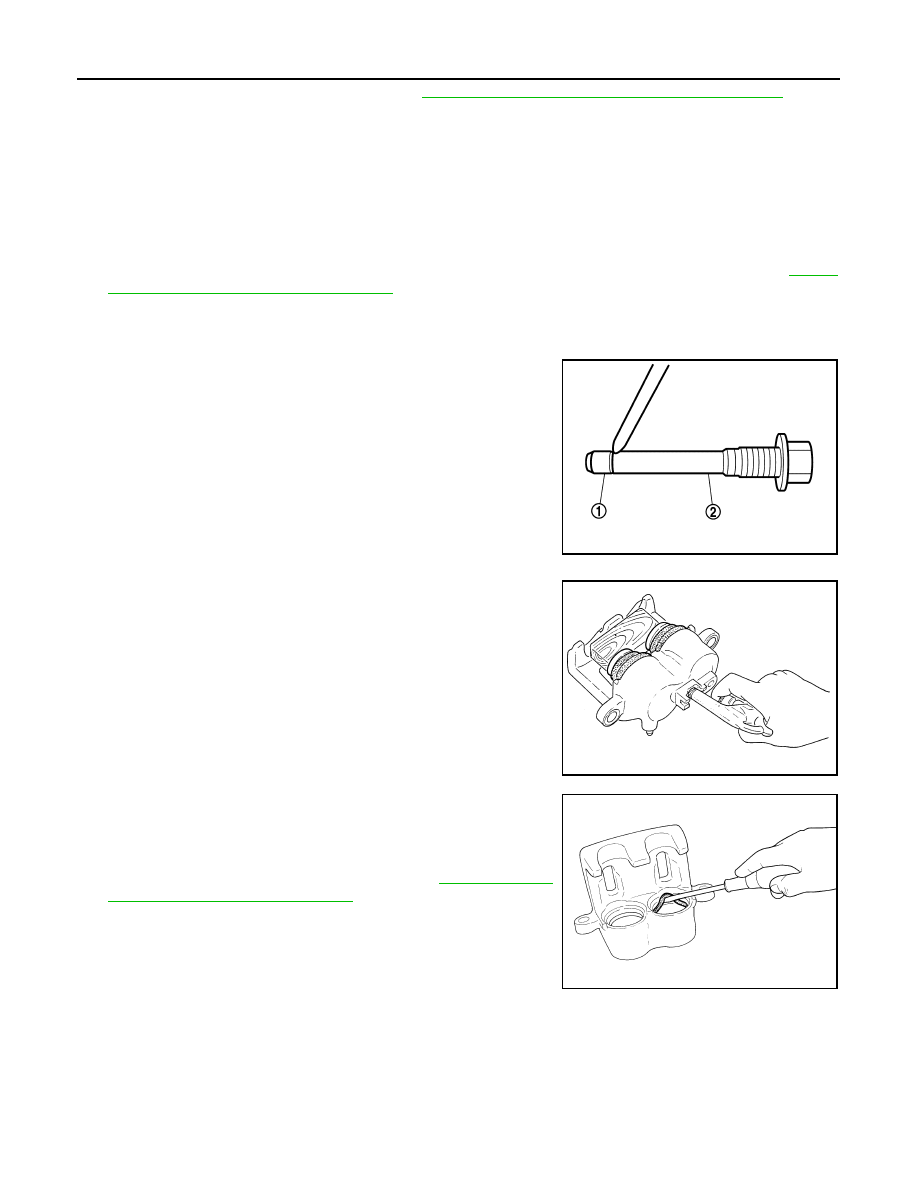

Remove bushing (1) from sliding pin bolt (2).

4.

Place a wooden block as shown in the figure, and blow air from

union bolt mounting hole to remove pistons and piston boots.

CAUTION:

Never get fingers caught in the pistons.

5.

Remove piston seal from cylinder body using seal pick tool.

CAUTION:

Be careful not to damage a cylinder inner wall.

6.

Remove bleeder valve and cap.

7.

Perform inspection after disassembly. Refer to

CALIPER ASSEMBLY : Inspection"

.

ASSEMBLY

CAUTION:

Never drop the parts.

1.

Install bleeder valve and cap.

JSFIA0496ZZ

BRB0032D

SFIA0141E