Content .. 1195 1196 1197 1198 ..

Nissan Quest E52. Manual - part 1197

TM-18

< SYSTEM DESCRIPTION >

[CVT: RE0F09B]

STRUCTURE AND OPERATION

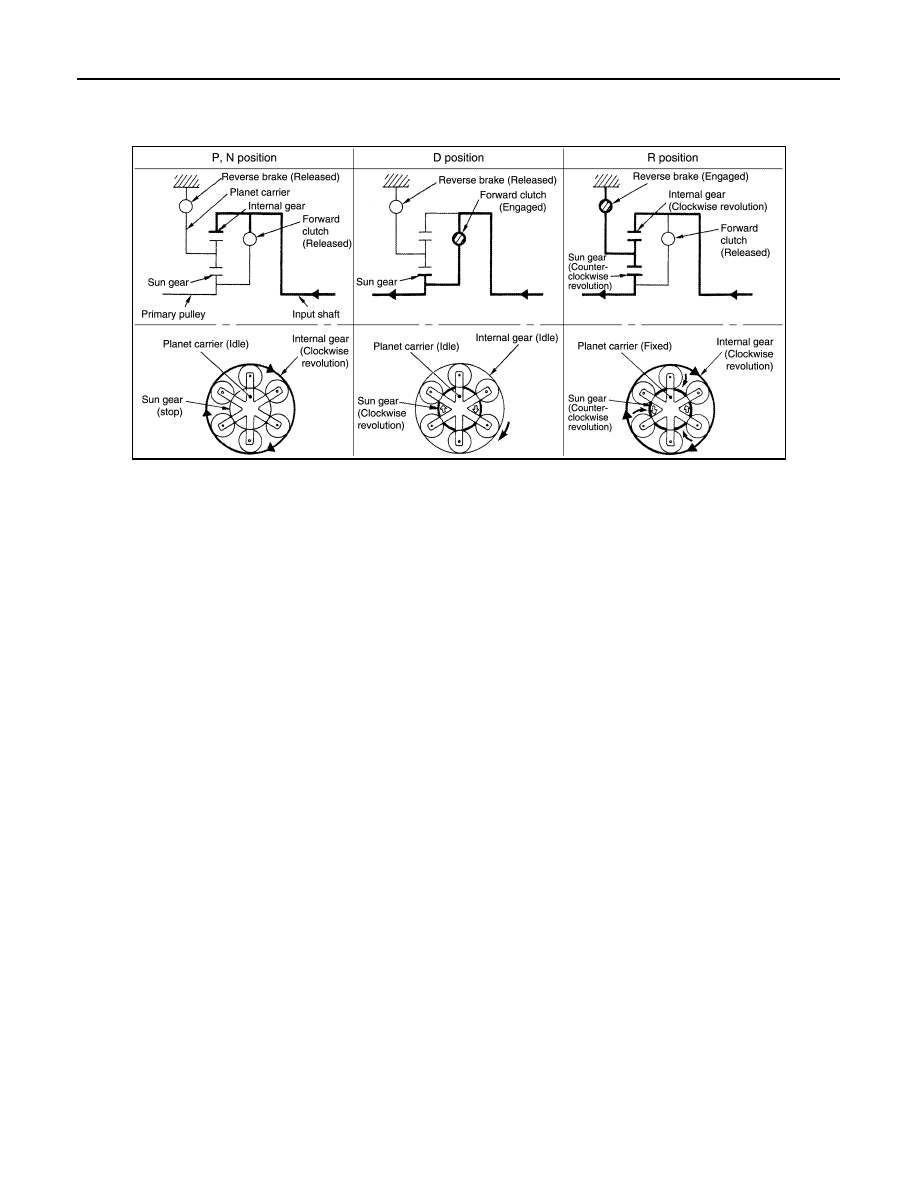

• The power from the torque converter is input via the input shaft, operating a wet multi-plate clutch by means

of hydraulic pressure to switch between forward and reverse driving.

PLANETARY GEAR OPERATION

TRANSAXLE : Belt & Pulley

INFOID:0000000009650080

It is composed of a pair of pulleys (the groove width is changed freely in the axial direction) and the steel belt

(the steel plates are placed continuously and the belt is guided with the multilayer steel rings on both sides).

JPDIA0951GB