Content .. 1172 1173 1174 1175 ..

Nissan Quest E52. Manual - part 1174

ST-22

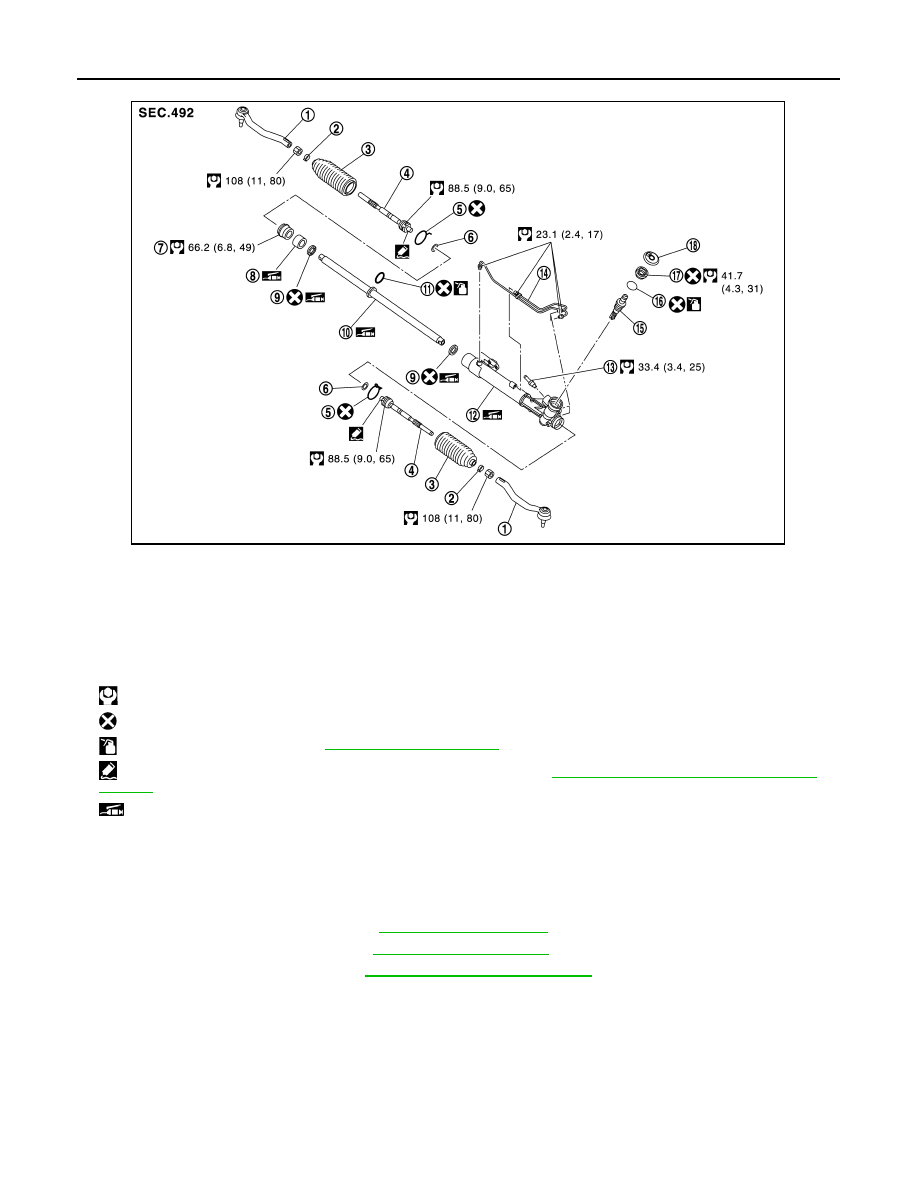

< REMOVAL AND INSTALLATION >

STEERING GEAR AND LINKAGE

Removal and Installation

INFOID:0000000009648915

REMOVAL

1.

Set the vehicle to the straight-ahead position.

2.

Remove tires with power tool. Refer to

.

3.

Remove engine under cover. Refer to

.

4.

Remove exhaust front tube. Refer to

EX-6, "Removal and Installation"

5.

Remove heat insulator from front suspension member.

6.

Remove cotter pin, and then loosen the nut.

1.

Outer socket

2.

Boot clamp

3.

Boot

4.

Inner socket

5.

Boot clamp (stainless wire)

6.

Spacer

7.

End cover assembly

8.

Rack spacer

9.

Rack oil seal

10. Rack assembly

11.

O-ring

12. Gear housing assembly

13. Low pressure piping

14. Cylinder tubes

15. Gear-sub assembly

16. O-ring

17. Rear cover

18. Rear cover cap

: N·m (kg-m, ft-lb)

: Always replace after every disassembly.

: Apply power steering fluid. Refer to

MA-10, "Fluids and Lubricants"

.

: Apply Genuine High Strength Thread Locking Sealant or equivalent. Refer to

GI-22, "Recommended Chemical Products and

.

: Apply multi-purpose grease.

JSGIA0936GB