Content .. 1057 1058 1059 1060 ..

Nissan Quest E52. Manual - part 1059

POWER RETURN MOTOR

SE-65

< DTC/CIRCUIT DIAGNOSIS >

C

D

E

F

G

H

I

K

L

M

A

B

SE

N

O

P

POWER RETURN MOTOR

LH

LH : Diagnosis Procedure

INFOID:0000000009652965

1.

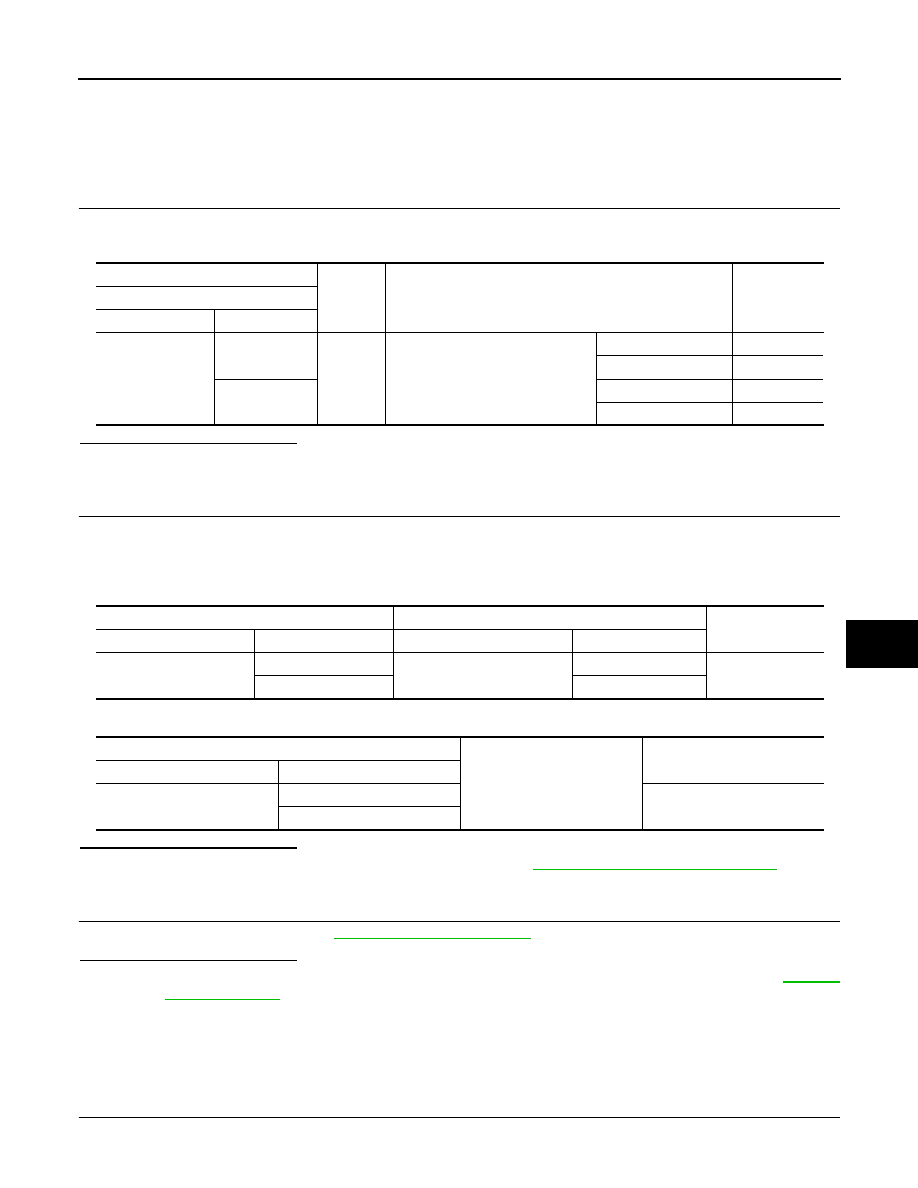

CHECK POWER RETURN MOTOR (LH) INPUT SIGNAL

1.

Turn ignition switch OFF.

2.

Check voltage between power return motor assembly (LH) harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> GO TO 2.

2.

CHECK POWER RETURN MOTOR (LH) CIRCUIT

1.

Disconnect seatback power return control unit connector and power return motor assembly (LH) connec-

tor.

2.

Check continuity between seatback power return control unit harness connector and power return motor

assembly (LH) harness connector.

3.

Check continuity between seatback power return control unit harness connector and ground.

Is the inspection result normal?

YES

>> Replace seatback power return control unit. Refer to

SE-139, "Removal and Installation"

NO

>> Repair or replace harness.

3.

CHECK INTERMITTENT INCIDENT

Check intermittent incident. Refer to

GI-42, "Intermittent Incident"

.

Is the inspection result normal?

YES

>> Replace power return motor assembly (LH) [reclining device assembly (LH)]. Refer to

NO

>> Repair or replace harness.

RH

RH : Diagnosis Procedure

INFOID:0000000009652966

1.

CHECK POWER RETURN MOTOR (RH) INPUT SIGNAL

1.

Turn ignition switch OFF.

(+)

(–)

Condition

Voltage (V)

Power return motor assembly (LH)

Connector

Terminal

B498

1

Ground

Power return motor assembly (LH)

Reverse operation

9 – 16

Other than the above

0 – 0.5

5

Return operation

9 – 16

Other than the above

0 – 0.5

Seatback power return control unit

Power return motor assembly (LH)

Continuity

Connector

Terminal

Connector

Terminal

B487

5

B498

1

Existed

6

5

Seatback power return control unit

Ground

Continuity

Connector

Terminal

B487

5

Not existed

6