Nissan Cube. Manual - part 347

EC-274

< DTC/CIRCUIT DIAGNOSIS >

[MR18DE]

P0448 EVAP CANISTER VENT CONTROL VALVE

Check the following.

• EVAP canister for damage

• EVAP hose between EVAP canister and vehicle frame for clogging or poor connection

>> Repair hose or replace EVAP canister. Refer to

6.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR CONNECTOR

1.

Disconnect EVAP control system pressure sensor harness connector.

2.

Check connectors for water.

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> Replace EVAP control system pressure sensor.

7.

CHECK EVAP CONTROL SYSTEM PRESSURE SENSOR

EC-279, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> Replace EVAP control system pressure sensor.

8.

CHECK INTERMITTENT INCIDENT

GI-40, "Intermittent Incident"

>> INSPECTION END

Component Inspection

INFOID:0000000009947388

1.

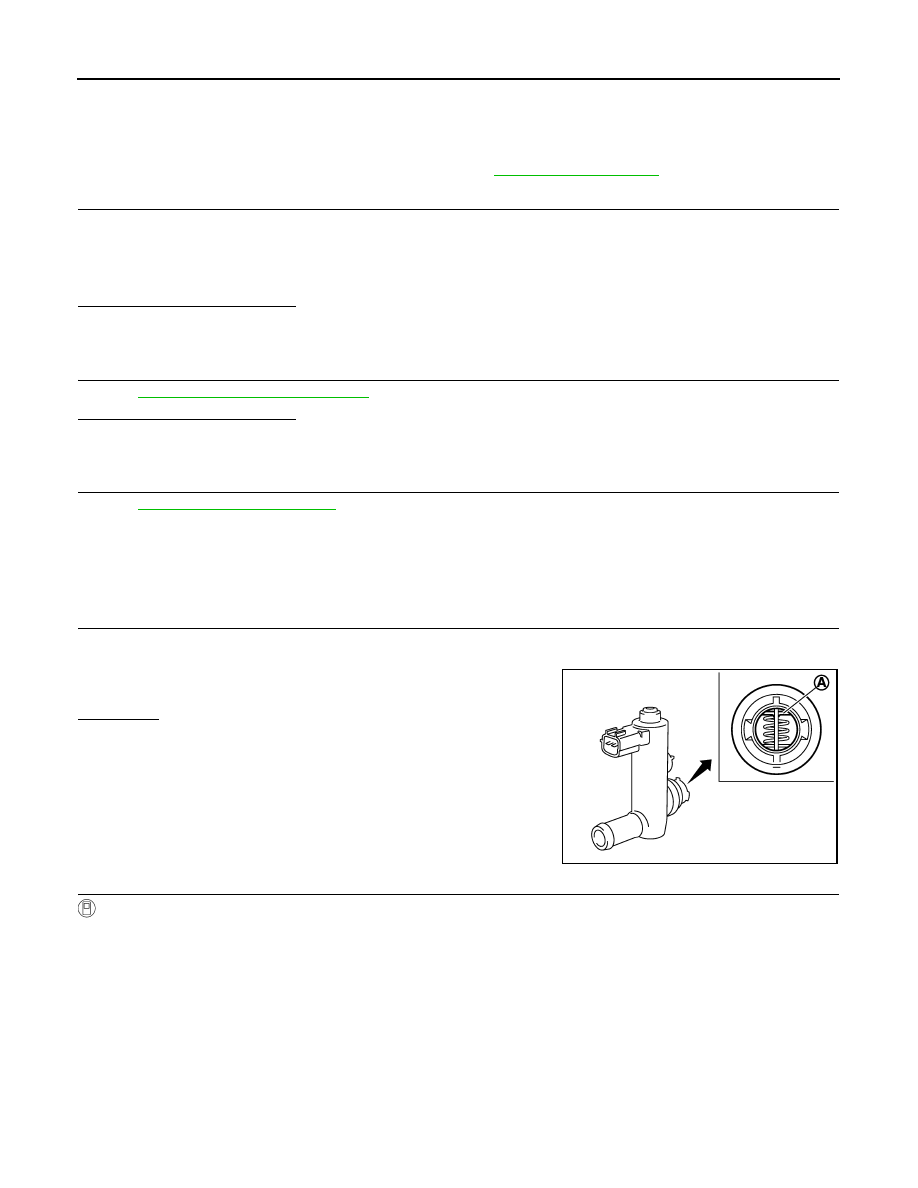

CHECK EVAP CANISTER VENT CONTROL VALVE-I

1.

Turn ignition switch OFF.

2.

Remove EVAP canister vent control valve from EVAP canister.

3.

Check portion (A) of EVAP canister vent control valve for being

rusted.

Is it rusted?

YES

>> Replace EVAP canister vent control valve.

NO

>> GO TO 2.

2.

CHECK EVAP CANISTER VENT CONTROL VALVE-II

With CONSULT

1.

Reconnect harness connectors disconnected.

2.

Turn ignition switch ON.

3.

Perform “VENT CONTROL/V” in “ACTIVE TEST” mode.

Water should not exist.

JMBIA0168ZZ