Nissan Cube. Manual - part 97

BRC-38

< DTC/CIRCUIT DIAGNOSIS >

[VDC/TCS/ABS]

C1110, C1153, C1170 ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

C1110, C1153, C1170 ABS ACTUATOR AND ELECTRIC UNIT (CONTROL

UNIT)

DTC Logic

INFOID:0000000009949931

DTC DETECTION LOGIC

DTC CONFIRMATION PROCEDURE

1.

PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn ignition switch OFF and

wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.

DTC REPRODUCTION PROCEDURE

1.

Turn the ignition switch ON.

2.

Perform self-diagnosis for “ABS” with CONSULT.

Is DTC “C1110”, “C1153” or “C1170” detected?

YES

>> Proceed to diagnosis procedure. Refer to

.

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000009949932

1.

REPLACE ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)

CAUTION:

Replace ABS actuator and electric unit (control unit) when self-diagnostic result shows items other

than those applicable.

>> Replace ABS actuator and electric unit (control unit). Refer to

.

Special Repair Requirement

INFOID:0000000009949933

1.

ADJUSTMENT OF STEERING ANGLE SENSOR NEUTRAL POSITION

Always perform the neutral position adjustment for the steering angle sensor, when replacing the ABS actua-

tor and electric unit (control unit) or steering angle sensor and removing steering angle sensor. Refer to

9, "Special Repair Requirement"

>> END

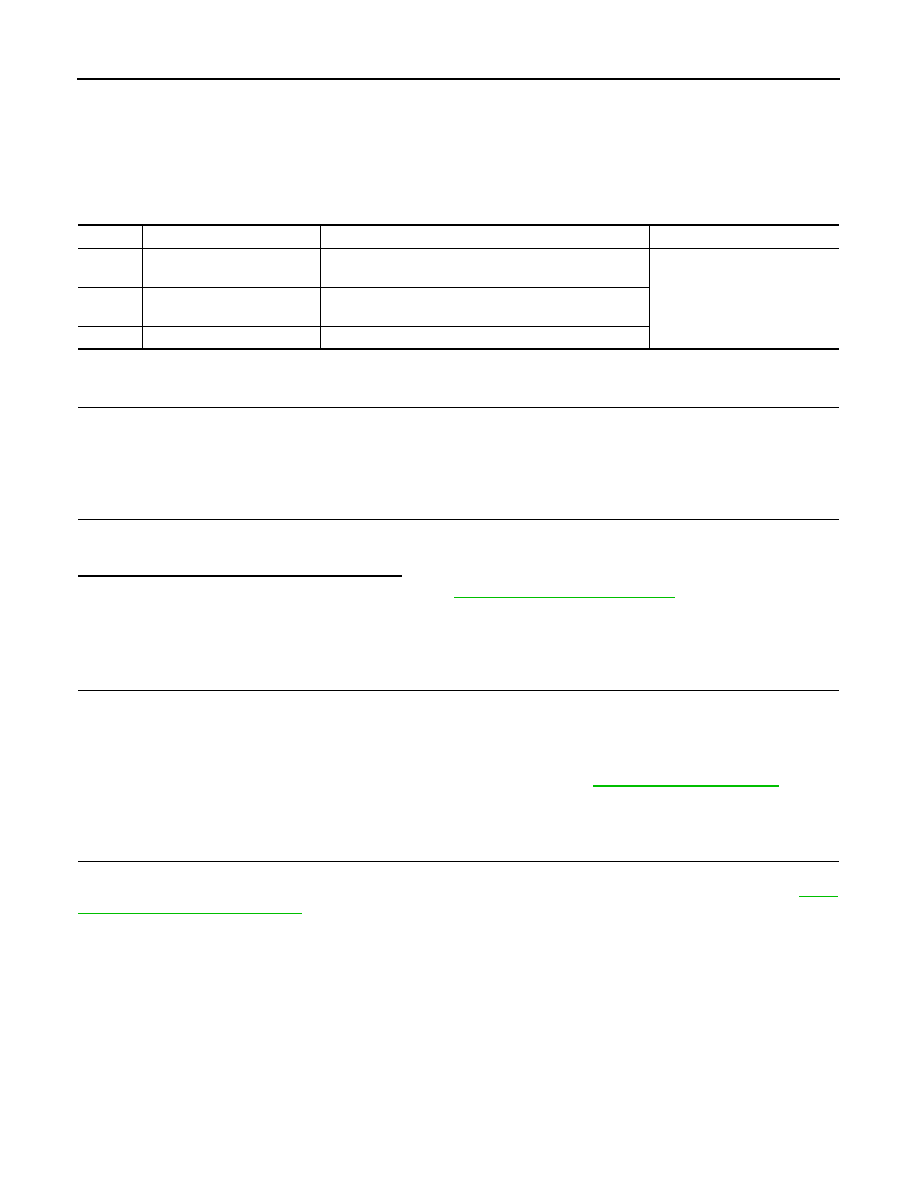

DTC

Display item

Malfunction detected condition

Possible cause

C1110

CONTROLLER FAILURE

When there is an internal malfunction in the ABS actuator

and electric unit (control unit).

ABS actuator and electric unit

(control unit)

C1153

EMERGENCY BRAKE

When ABS actuator and electric unit (control unit) is mal-

functioning. (Pressure increase is too much or too little)

C1170

VARIANT CODING

In a case where VARIANT CODING is different.