Nissan Cube. Manual - part 87

REAR DRUM BRAKE

BR-41

< REMOVAL AND INSTALLATION >

C

D

E

G

H

I

J

K

L

M

A

B

BR

N

O

P

• After installing the retainer ring, close the joint of retainer ring until securely closed.

• When disassembled adjuster, confirm the difference between left and right wheel for assemble.

• Apply PBC (Poly Butyl Cuprysil) silicone-based grease to the adjuster screw.

• Apply PBC (Poly Butyl Cuprysil) silicone-based grease to the mating faces between the adjuster and brake

shoe.

• Apply PBC (Poly Butyl Cuprysil) silicone-based grease to the mating faces between the back plate and

brake shoe.

• Shorten adjuster by rotating it.

• Install the brake shoe assembly so that it does damage the wheel cylinder.

• Check the component parts of brake shoe assembly are installed properly.

• Check the brake shoe sliding surface and brake drum inner surface for grease. Wipe it out any adheres to

the surfaces.

• Perform the air bleeding when removed or disassembled the wheel cylinder. Refer to

.

• Never allow foreign matter (e.g. dust) and oils other than brake fluid to enter the reservoir tank.

• Adjust the brake shoe (parking brake lever stroke) after install and air bleeding. Refer to

Disassembly and Assembly

INFOID:0000000009949241

DISASSEMBLY

1.

Remove the boot from wheel cylinder. Refer to

.

2.

Remove the piston, piston cup and spring from wheel cylinder.

CAUTION:

Pull the piston out from the wheel cylinder to prevent the wheel cylinder inner wall from being

damaged.

3.

Remove boot and piston cup from piston.

ASSEMBLY

1.

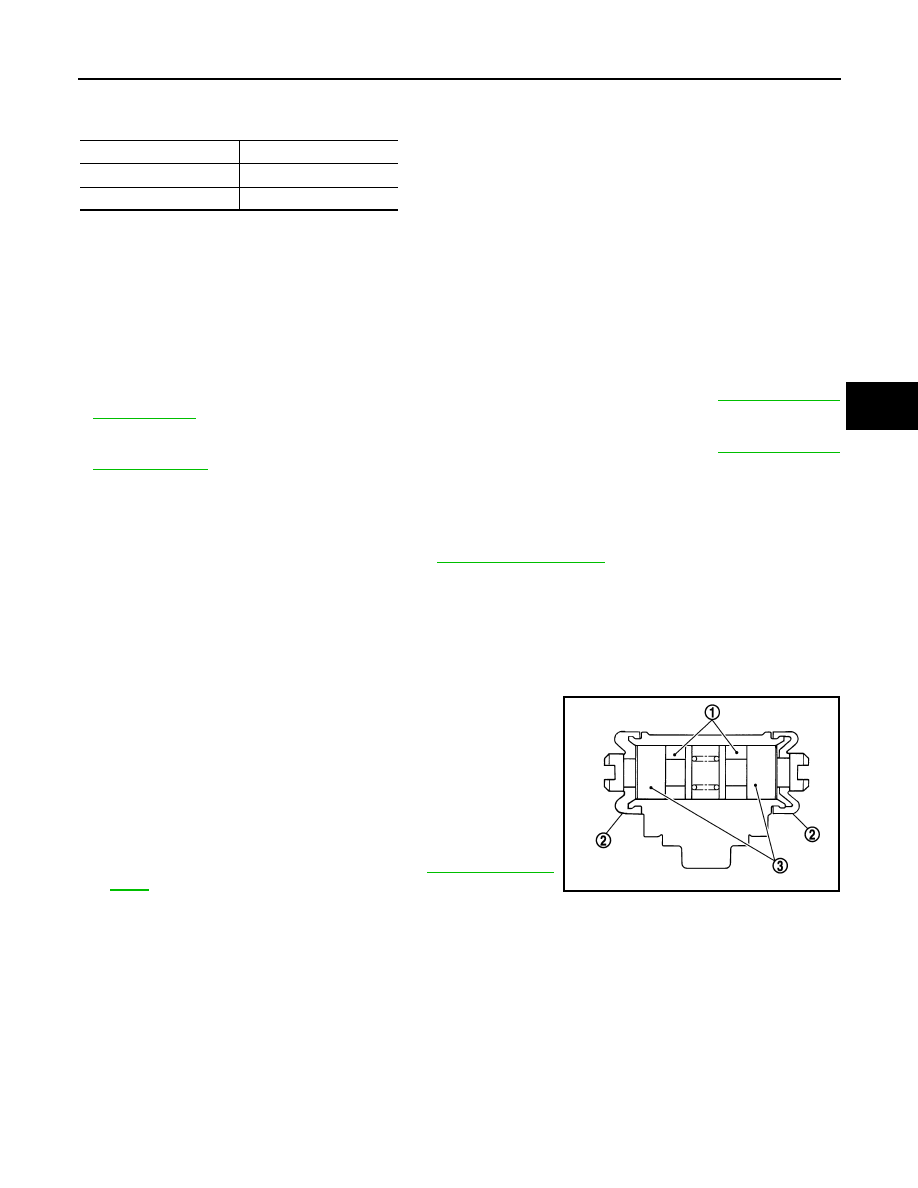

Apply polyglycol ether based lubricant to the piston cup (1) and

boot (2), and install them to piston (3).

CAUTION:

• Never mistake the direction.

• Never reuse piston cup and boot.

2.

Apply brake fluid to piston and wheel cylinder inner wall, and

install spring and piston to wheel cylinder.

CAUTION:

Never damage the wheel cylinder inner wall.

3.

Install the boot to wheel cylinder. Refer to

.

Inspection and Adjustment

INFOID:0000000009949242

INSPECTION AFTER REMOVAL

Check the following items and replace if necessary.

• Check the brake lining for excessive wear, damage, and peeling.

• Check the brake shoe sliding surface for excessive wear and damage.

• Check each spring for settling, excessive wear, damage, and rust.

• Check the adjuster for smoothness, and check it for excessive wear, damage, and rust.

• Check the back plate for damage, cracks, and deformation.

• Check the wheel cylinder for cracks, damage, and leakage of brake fluid.

• Visually check the brake drum for excessive wear, cracks, and damage with a pair of vernier calipers.

• Check the drum brake component parts for excessive wear, damage, and rust.

INSPECTION AFTER DISASSEMBLY

Adjuster

Direction

Left side

Left screw

Right side

Right screw

JPFIA0234ZZ