Nissan Versa Note. Manual - part 812

TM-128

< BASIC INSPECTION >

[CVT: RE0F11A]

ADDITIONAL SERVICE WHEN REPLACING TRANSAXLE ASSEMBLY

ADDITIONAL SERVICE WHEN REPLACING TRANSAXLE ASSEMBLY

Description

INFOID:0000000009019639

When replacing the transaxle, perform the following work.

ERASING THE CALIBRATION DATA

• The TCM acquires calibration data (individual characteristic value) of each solenoid that is stored in the

ROM assembly (in the control valve). This enables the TCM to perform accurate control. For this reason,

after the transaxle assembly is replaced, it is necessary to erase the calibration data that is stored in the

TCM and load new calibration data.

ERASING THE LEARNED VALUE DATA

• TCM learns indicated pressure for appropriate control of the transaxle assembly and records the learned

values. For this reason, the leaned values stored in TCM must be erased after replacing a transaxle assem-

bly.

ERASING CVT FLUID DEGRADATION LEVEL DATA

• TCM records the degradation level of the CVT fluid calculated from the vehicle driving status. Therefore, if

the transaxle assembly is replaced, it is necessary to erase the CVT fluid degradation level data recorded by

TCM.

Procedure

INFOID:0000000009019640

1.

INITIALIZE TCM

With CONSULT

1. Set parking brake.

2. Turn ignition switch ON.

3. Select “Work Support” in “TRANSMISSION”.

4. Select “ERASE MEMORY DATA”.

5. While maintaining the conditions below, touch “Start”.

-

Vehicle stop status

-

With engine stopped

-

Selector lever: “R” position

-

Accelerator pedal: Depressed

NOTE:

Select “Start” and complete within approximately 20 seconds.

Is “COMPLETED” displayed?

YES

>> GO TO 2.

NO

>> Turn the ignition switch OFF and wait for a minimum of 10 seconds then perform the work again.

2.

CHECK AFTER TCM IS INITIALIZED

With CONSULT

1. Turn ignition switch OFF with the selector lever in “R” position and wait for 10 seconds or more.

2. Turn ignition switch ON with the selector lever in “R” position.

CAUTION:

Never start the engine.

3. Select “Special function” in “TRANSMISSION”.

4. Select “CALIB DATA”.

5. Check that indicated value of “CALIB DATA” is equal to the value shown in the following table.

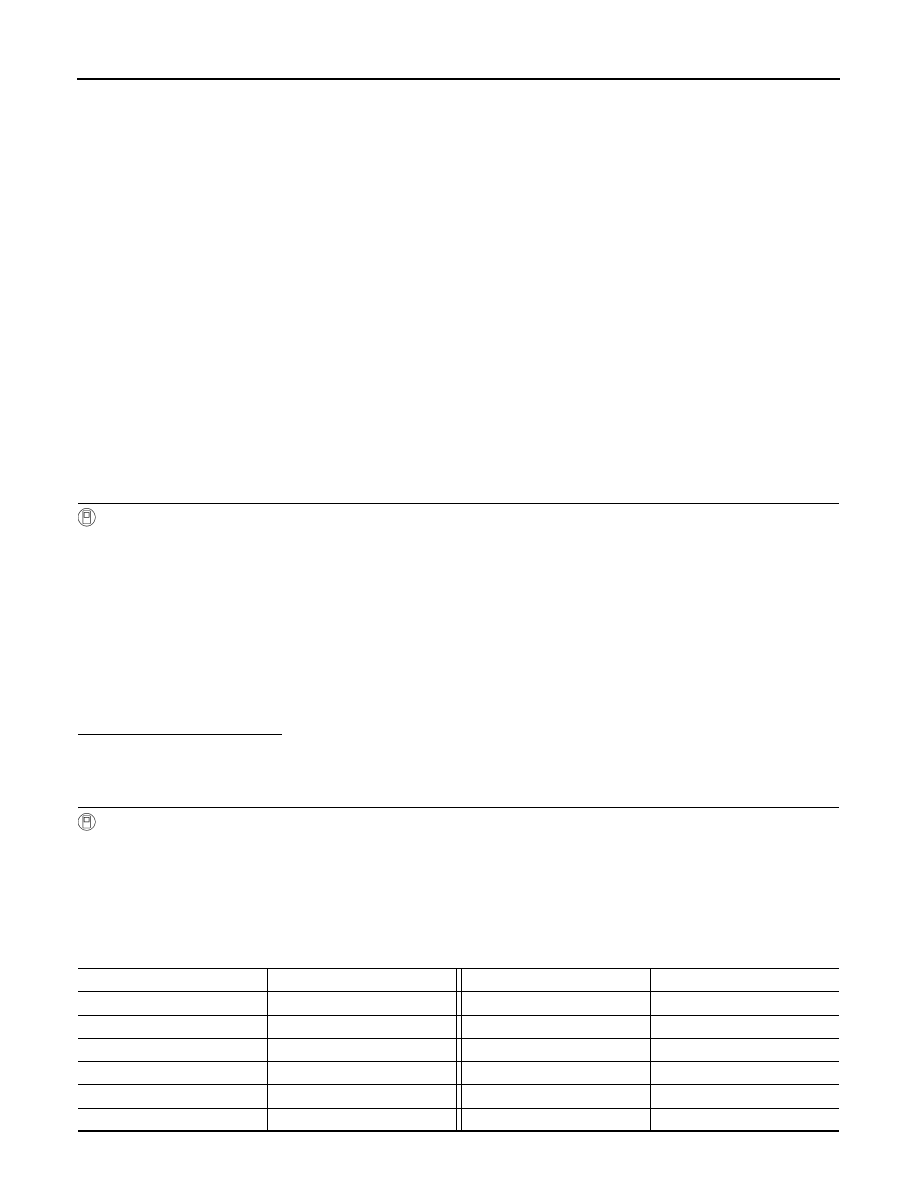

Item name

Display value

Item name

Display value

UNIT CLB ID1

00

MAP NO HC/RB

00

UNIT CLB ID2

00

MAP NO L/B

00

UNIT CLB ID3

00

OFFSET2 LU

0

UNIT CLB ID4

00

OFFSET2 PL

0

UNIT CLB ID5

00

OFFSET2 PRI

0

UNIT CLB ID6

00

OFFSET2 H/R

0