Nissan Versa Note. Manual - part 488

HA-22

< PERIODIC MAINTENANCE >

OIL

Oil Adjusting Procedure for Compressor Replacement

INFOID:0000000008968517

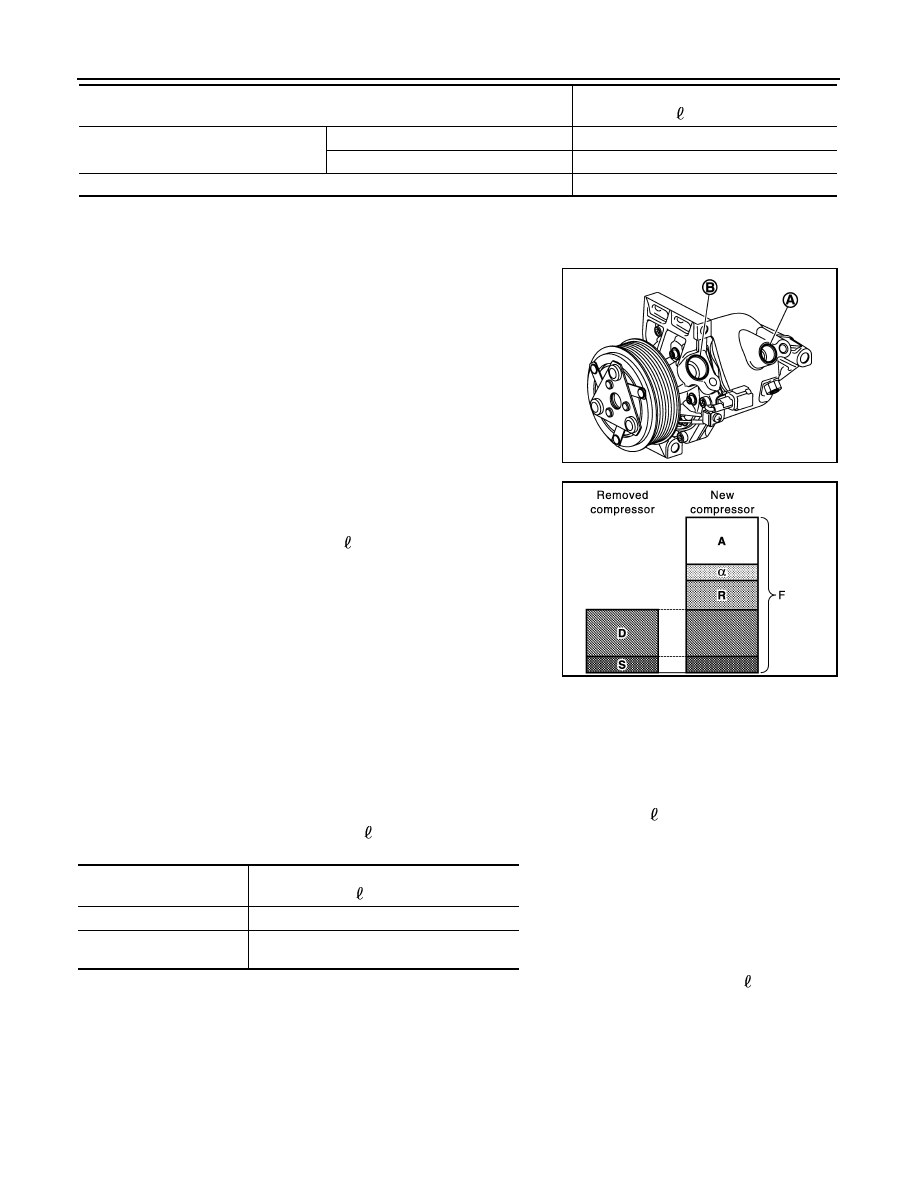

1. Drain oil from removed compressor and measure amount drained.

• Drain oil from high-pressure port (A) and low-pressure port (B)

while rotating magnet clutch.

• Measure total amount of oil that is drained from removed com-

pressor.

2. Drain oil from a new compressor that is calculated according to

the following conditions.

CAUTION:

If oil amount that is drained from removed compressor is less than 60 m (2.1 Imp fl oz.), perform

calculation by setting “D” as 40 m (1.4 Imp fl oz.).

Example: Oil amount to be drained from a new compressor when replacing compressor [m (Imp fl oz.)]

[D = 60 (2.1),

α = 5 (0.2)]

120 (4.2)

− [60 (2.1) + 20 (0.7) + 5 (0.2)] = 35 (1.1)

3. Install compressor and check the operation.

Refrigerant leak is detected

Large amount leakage

30 (1.1)

Small amount leakage

—

Oil amount that is recycled together with refrigerant during recycle operation

α

Conditions

Oil amount to be added to A/C system

m (Imp fl oz.)

JMIIA0940ZZ

Amount to be drained (A) [m (Imp fl oz.)] = F

− (D

+ S + R +

α)

F:

Oil amount that a new compressor contains

[120 (4.2)]

D: Oil amount that is drained from removed com-

pressor

S: Oil amount that remains inside of removed

compressor [20 (0.7)]

R: Oil amount to be added according to compo-

nents that are removed except compressor

α: Oil amount that is recycled together with re-

frigerant during recycle operation

Conditions

Oil amount to be added to A/C system

m (Imp fl oz.)

Replace evaporator

35 (1.2)

Replace condenser (in-

cludes liquid tank)

20 (0.7)

JPIIA1455GB