Nissan Versa Note. Manual - part 485

HA-10

< PREPARATION >

PREPARATION

Sealant and/or Oil

INFOID:0000000009457537

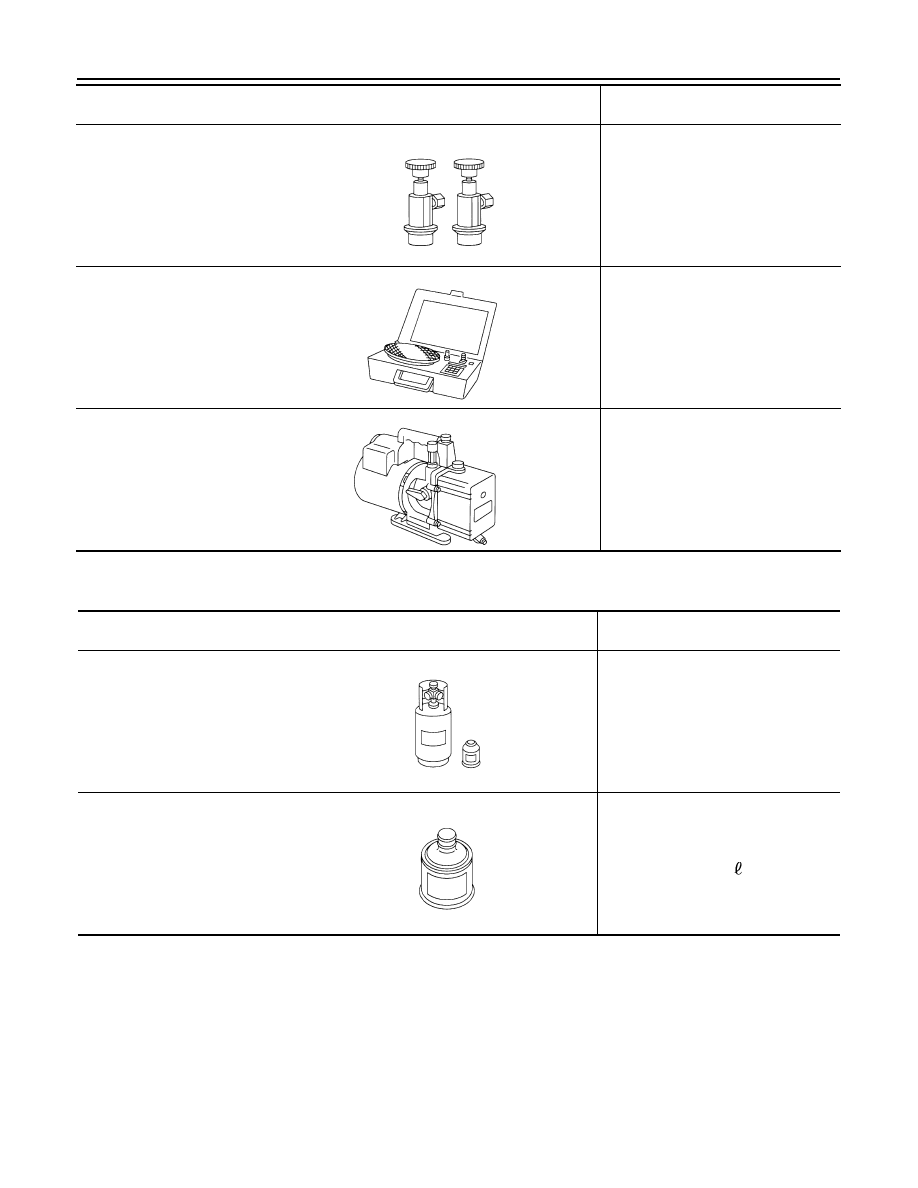

Service couplers

• High side coupler

(J-39500-20A)

• Low side coupler

(J-39500-24A)

Hose fitting to service hose:

• M14 x 1.5 fitting is optional or per-

manently attached.

(J-39699)

Refrigerant weight scale

For measuring of refrigerant

Fitting size-Thread size

• 1/2”-16 ACME

(J-39649)

Vacuum pump

(Including the isolator valve)

Capacity:

• Air displacement: 4 CFM

• Micron rating: 20 microns

• Oil capacity: 482 g (17 oz)

Fitting size-Thread size

• 1/2”-16 ACME

(Kent-Moore No.)

Tool name

Description

S-NT202

S-NT200

S-NT203

(Kent-Moore No.)

Tool name

Description

( — )

HFC-134a (R-134a) Refrigerant

Container color: Light blue

Container marking: HFC-134a (R-

134a)

Fitting size: Thread size

• large container 1/2”-16 ACME

( — )

NISSAN A/C System Oil Type DH-

PR

Type: Poly alkylene glycol (PAG), type

DH-PR

Application: HFC-134a (R-134a) Vane-

rotary compressors

Capacity: 110 - 130 m (3.7 - 4.4 US fl

oz, 3.9 - 4.6 Imp fl oz)

S-NT196

JMIIA1759ZZ