Nissan Versa Note. Manual - part 398

EM-108

< UNIT DISASSEMBLY AND ASSEMBLY >

[HR16DE]

CYLINDER BLOCK

CAUTION:

Do not rotate crankshaft.

• Remove main bearing cap and bearings, and using the scale (A)

on the plastigage bag, measure the plastigage width.

NOTE:

The procedure when the measured value exceeds the limit is

same as that described in the “Method by Calculation”.

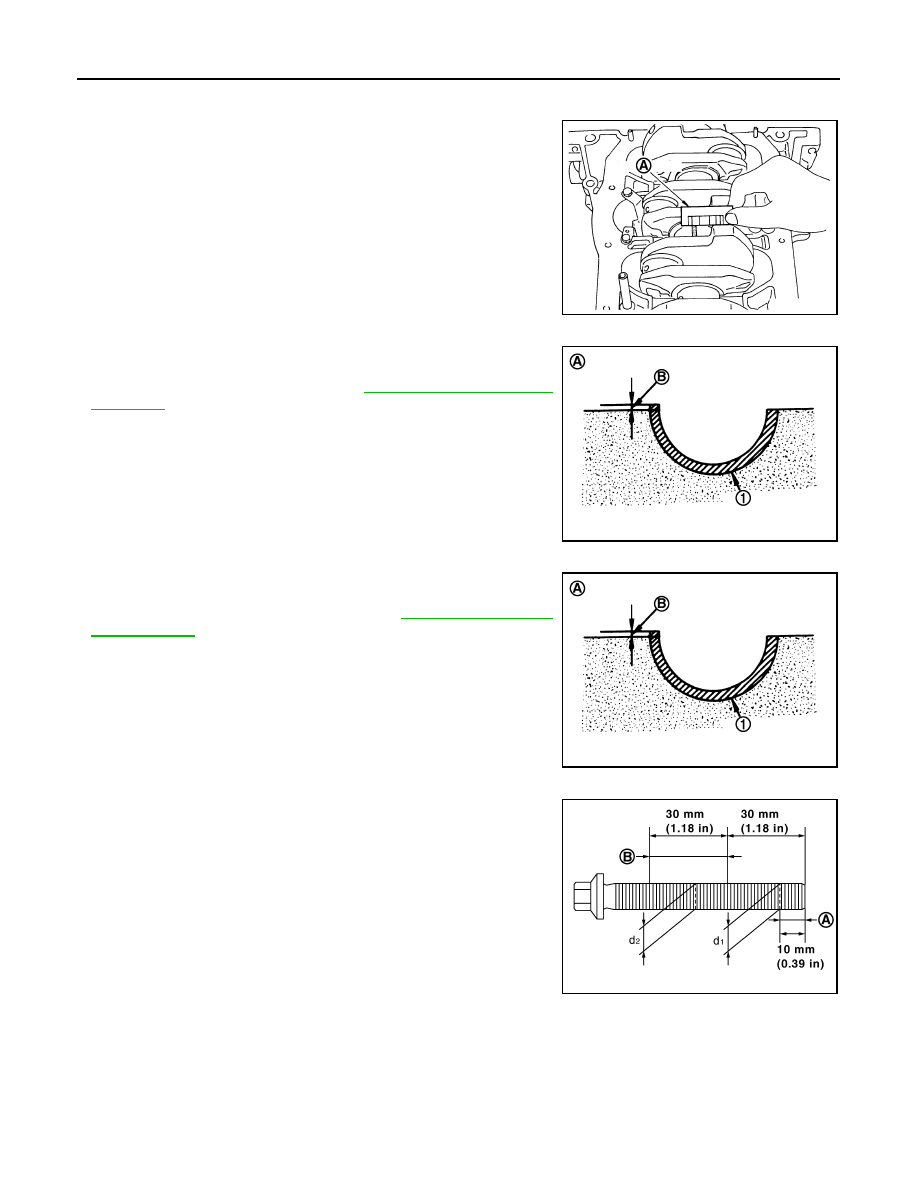

MAIN BEARING CRUSH HEIGHT

• When main bearing cap is removed after being tightened to the

specified torque with main bearings (1) installed, the tip end of

bearing must protrude (B). Refer to

• If the standard is not met, replace main bearings.

CONNECTING ROD BEARING CRUSH HEIGHT

• When connecting rod cap is removed after being tightened to the

specified torque with connecting rod bearings (1) installed, the tip

end of bearing must protrude (B). Refer to

.

• If the standard is not met, replace connecting rod bearings.

MAIN BEARING CAP BOLT OUTER DIAMETER

• Measure the outer diameters (d

1

) and (d

2

) at two positions as

shown.

• If reduction appears in places other than (B) range, regard it as

(d

2

).

• If it exceeds the limit (a large difference in dimensions), replace

main bearing cap bolt with a new one.

CONNECTING ROD CAP BOLT OUTER DIAMETER

PBIC3278J

(A)

: Example

Standard

: There must be crush height.

PBIC3279J

(A)

: Example

Standard

: There must be crush height.

PBIC3279J

(A)

: (d1) measuring position

(B)

: (d2) measuring position

Limit [(d

1

) – (d

2

)]: 0.2 mm (0.0078 in)

PBIC4015E