Nissan Versa Note. Manual - part 393

EM-88

< UNIT REMOVAL AND INSTALLATION >

[HR16DE]

ENGINE ASSEMBLY

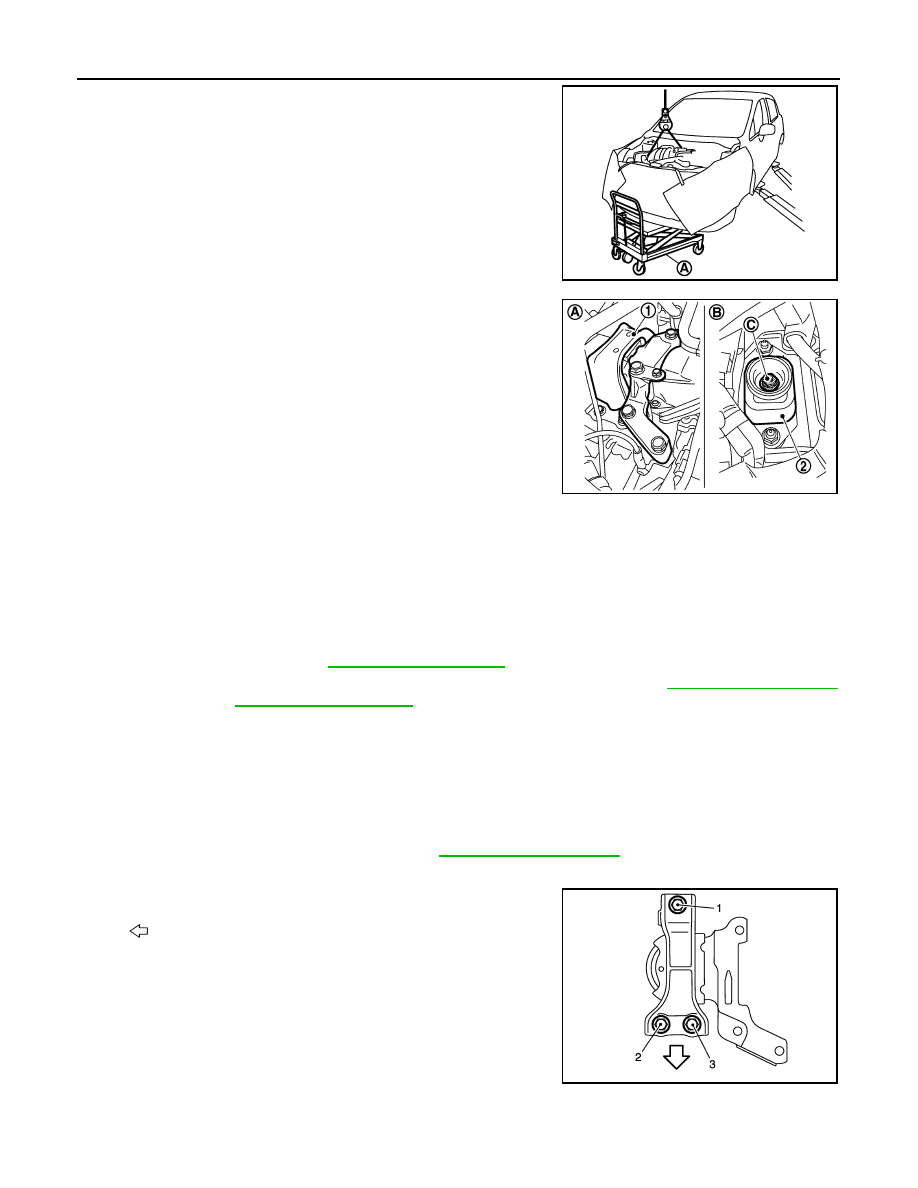

22. Use a suitable jack (A) to securely support the bottom of the

engine and the transaxle assembly.

CAUTION:

Put a piece of wood or an equivalent as the supporting sur-

face and secure in a stable condition.

23. Remove engine mounting insulator (RH) (1).

24. Remove engine through bolt-securing nut (C).

25. Carefully lower suitable jack, or raise lift to remove the engine and the transaxle assembly. Observe the

following cautions:

CAUTION:

• Check that no part interferes with the vehicle side.

• Before and during lifting, always check if any harnesses are left connected.

• During removal, always be careful to prevent the vehicle from falling off the lift due to changes in

the center of gravity.

• If necessary, support the vehicle by setting jack or suitable tool at the rear.

26. Remove starter motor. Refer to

.

27. Lift with a hoist and separate the engine from the transaxle assembly. Refer to

(CVT models).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Do not allow engine oil to get on engine mounting insulator. Be careful not to damage engine mount-

ing insulator.

• Check that each mounting insulator is seated properly, and tighten nuts and bolts.

• When installation directions are specified, install parts according to the direction marks on them,

referring to the figure of components. Refer to

Engine Mounting Insulator (RH)

• Tighten bolts in the numerical order as shown.

INSPECTION AFTER INSTALLATION

PBIC3223J

(2)

: Engine mounting insulator (LH)

(A)

: Engine front side

(B)

: Transaxle side

JSBIA1223ZZ

: Front

JPBIA2809ZZ