Nissan Versa Note. Manual - part 387

EM-64

< REMOVAL AND INSTALLATION >

[HR16DE]

CAMSHAFT

10. Remove the intake valve timing control solenoid valve (1) and

the plug (2) securing the oil filter for intake valve timing control

solenoid valve.

11. Remove the exhaust valve timing control solenoid valve.

12. Remove the plug on the exhaust valve timing control solenoid

valve.

13. Remove the oil filter for exhaust valve timing control solenoid

valve.

14. For component inspection after removal, refer to

INSTALLATION

CAUTION:

Do not reuse O-rings or washers.

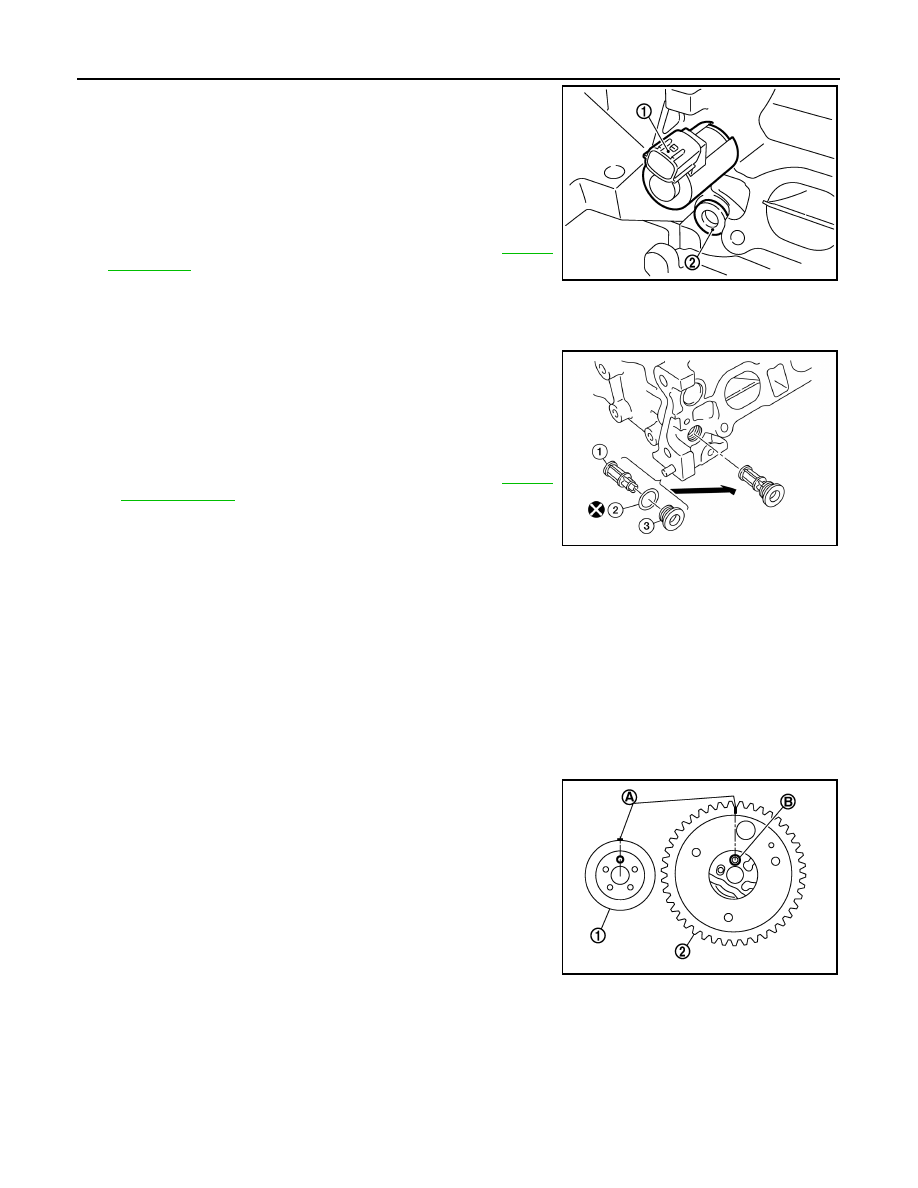

1. Install oil filter (1) for intake and exhaust valve timing control

solenoid valves.

CAUTION:

Do not reuse washers.

NOTE:

The intake side is shown as an example.

• The oil filter (1) and washer (2) are assembled to the plug (3),

and then install them in to the cylinder head. Refer to

.

2. Install intake and exhaust valve timing control solenoid valves.

• Insert it straight into the cylinder head.

• Tighten bolts.

CAUTION:

Do not reuse O-rings.

3. Install valve lifters.

• If they are reused, install them in the original positions.

4. Put a matching mark for positioning the camshaft (INT) and the camshaft sprocket (INT):

NOTE:

This helps prevent the knock pin from engaging with the incorrect pin hole after installing the camshaft

(INT) and the camshaft sprocket (INT).

a. Put the matching marks (A) on a line extending from the knock

pin position of camshaft (INT) (1) front surface.

• Put the marks on the visible position with the camshaft

sprocket installed as shown.

b. Put the matching marks on a line extending from the knock pin

hole (B) position of camshaft sprocket (INT) (2) as shown.

• Put the marks on the visible position with it installed to the

camshaft.

5. Put a matching mark for positioning the camshaft (EXH) and the camshaft sprocket (EXH):

NOTE:

This helps prevent the knock pin from engaging with the incorrect pin hole after installing the camshaft

(INT) and the camshaft sprocket (EXH).

PBIC3692E

AWBIA1146GB

PBIC3696E