Nissan Versa Note. Manual - part 361

EC-426

< DTC/CIRCUIT DIAGNOSIS >

[HR16DE]

ASCD BRAKE SWITCH

YES

>> GO TO 3.

NO

>> Repair or replace error-detected parts.

3.

CHECK ASCD BRAKE SWITCH

Check the ASCD brake switch. Refer to

EC-426, "Component Inspection (ASCD Brake Switch)"

Is the inspection result normal?

YES

>> Check intermittent incident. Refer to

GI-41, "Intermittent Incident"

.

NO

>> Replace ASCD brake switch. Refer to

Component Inspection (ASCD Brake Switch)

INFOID:0000000009020918

1.

CHECK ASCD BRAKE PEDAL POSITION SWITCH-I

1. Turn ignition switch OFF.

2. Disconnect ASCD brake switch harness connector.

3. Check the continuity between ASCD brake switch terminals as per the following conditions.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> GO TO 2.

2.

CHECK ASCD BRAKE SWITCH-II

1. Adjust ASCD brake switch installation. Refer to

BR-20, "Inspection and Adjustment"

2. Check the continuity between ASCD brake switch terminals as per the following conditions.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace ASCD brake switch. Refer to

.

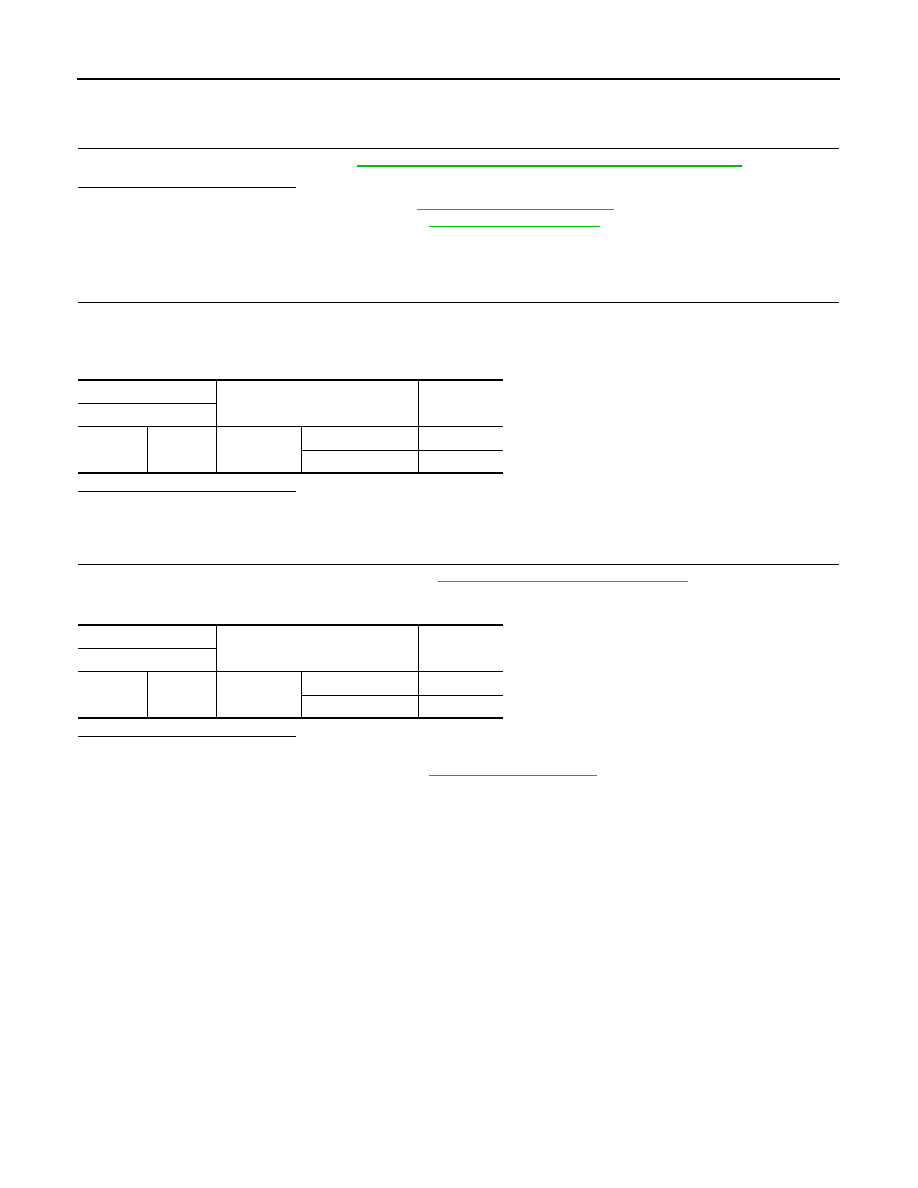

ASCD brake switch

Condition

Continuity

Terminal

1

2

Brake pedal

Fully released

Existed

Slightly depressed

Not existed

ASCD brake switch

Condition

Continuity

Terminal

1

2

Brake pedal

Fully released

Existed

Slightly depressed

Not existed