Nissan Versa Note. Manual - part 355

EC-402

< DTC/CIRCUIT DIAGNOSIS >

[HR16DE]

P2100, P2103 THROTTLE CONTROL MOTOR RELAY

2.

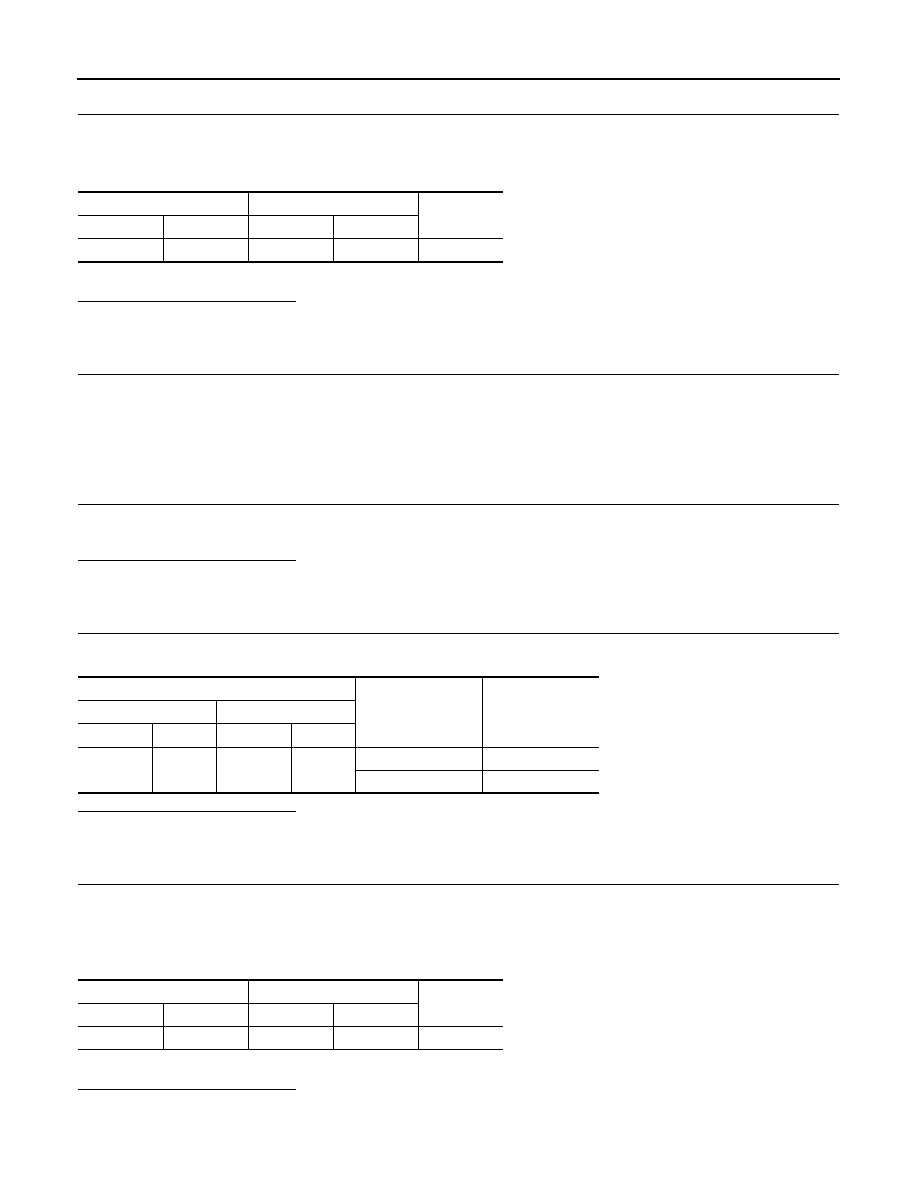

CHECK THROTTLE CONTROL MOTOR RELAY INPUT SIGNAL CIRCUIT-I

1. Disconnect ECM harness connector.

2. Disconnect IPDM E/R harness connector F115.

3. Check the continuity between ECM harness connector and IPDM E/R harness connector.

4. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> GO TO 3.

3.

DETECT MALFUNCTIONING PART

Check the following.

• IPDM E/R connector F42

• Harness for open or short between IPDM E/R and ECM

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.

CHECK FUSE

1. Disconnect 20 A fuse (No. 53) from IPDM E/R.

2. Check 20 A fuse for blown.

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> Replace 20 A fuse.

5.

CHECK THROTTLE CONTROL MOTOR RELAY INPUT SIGNAL CIRCUIT-I

1. Check voltage between ECM harness connector and ground under the following conditions.

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> GO TO 6.

6.

CHECK THROTTLE CONTROL MOTOR RELAY INPUT SIGNAL CIRCUIT-II

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Disconnect IPDM E/R harness connector F42.

4. Check the continuity between ECM harness connector and IPDM E/R harness connector.

5. Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> GO TO 7.

ECM

IPDM E/R

Continuity

Connector

Terminal

Connector

Terminal

F10

15

F42

32

Existed

ECM

Conditions

Voltage

+

−

Connector

Terminal

Connector

Terminal

F10

2

E16

108

Ignition switch: OFF

Approx. 0 V

Ignition switch: ON

Battery voltage

ECM

IPDM E/R

Continuity

Connector

Terminal

Connector

Terminal

F10

2

F42

29

Existed