Nissan Versa Note. Manual - part 261

EC-26

< SYSTEM DESCRIPTION >

[HR16DE]

COMPONENT PARTS

BATTERY TEMPERATURE SENSOR

Battery temperature sensor is integrated in battery current sensor.

The sensor measures temperature around the battery.

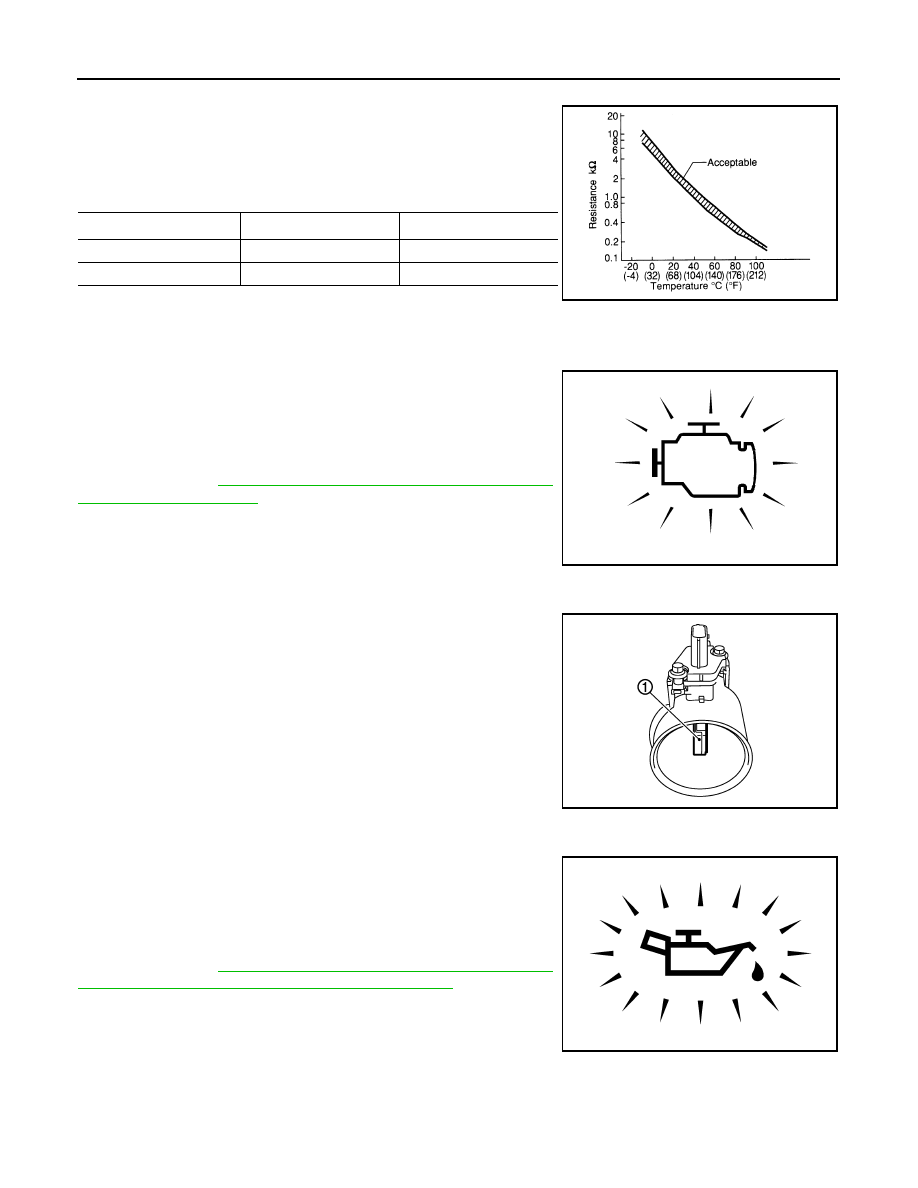

The electrical resistance of the thermistor decreases as temperature

increases.

<Reference data>

*: These data are reference values and are measured between battery temperature

sensor signal terminal and sensor ground.

Malfunction Indicator Lamp (MIL)

INFOID:0000000009020596

The MIL is located on the combination meter.

The MIL will illuminate when the ignition switch is turned ON without

the engine running. This is a bulb check.

When the engine is started, the MIL should turn OFF. If MIL remains

ON or continues blinking, the on board diagnostic system detects a

DTC(s) that affects exhaust gas.

For details, refer to

EC-57, "DIAGNOSIS DESCRIPTION : Malfunc-

.

Mass Air Flow Sensor

INFOID:0000000009020597

The mass air flow sensor (1) is placed in the stream of intake air. It

measures the intake flow rate by measuring a part of the entire

intake flow. The mass air flow sensor controls the temperature of the

hot wire to a certain amount. The heat generated by the hot wire is

reduced as the intake air flows around it. The more air, the greater

the heat loss.

Therefore, the electric current supplied to hot wire is changed to

maintain the temperature of the hot wire as air flow increases. The

ECM detects the air flow by means of this current change.

Oil Pressure Warning Lamp

INFOID:0000000009020598

Oil pressure warning lamp is located on the combination meter.

It indicates the low pressure of the engine oil and the malfunction of

the engine oil pressure system.

Combination meter turns the oil pressure warning lamp ON/OFF

according to the oil pressure warning lamp signal received from

ECM via CAN communication.

For details, refer to

EC-43, "ENGINE PROTECTION CONTROL AT

LOW ENGINE OIL PRESSURE : System Description"

Temperature [

°C (°F)]

Voltage

*

(V)

Resistance (k

Ω)

25 (77)

3.333

1.9 - 2.1

90 (194)

0.969

0.222 - 0.258

SEF012P

SAT652J

PBIA9559J

PBIA8559J