Nissan Note E12. Manual - part 246

IGNITION SIGNAL

EC-323

< DTC/CIRCUIT DIAGNOSIS >

[HR16DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Component Inspection (Condenser)

INFOID:0000000009022681

1.

CHECK CONDENSER

1. Turn ignition switch OFF.

2. Disconnect condenser harness connector.

3. Check resistance between condenser terminals as follows.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace condenser.

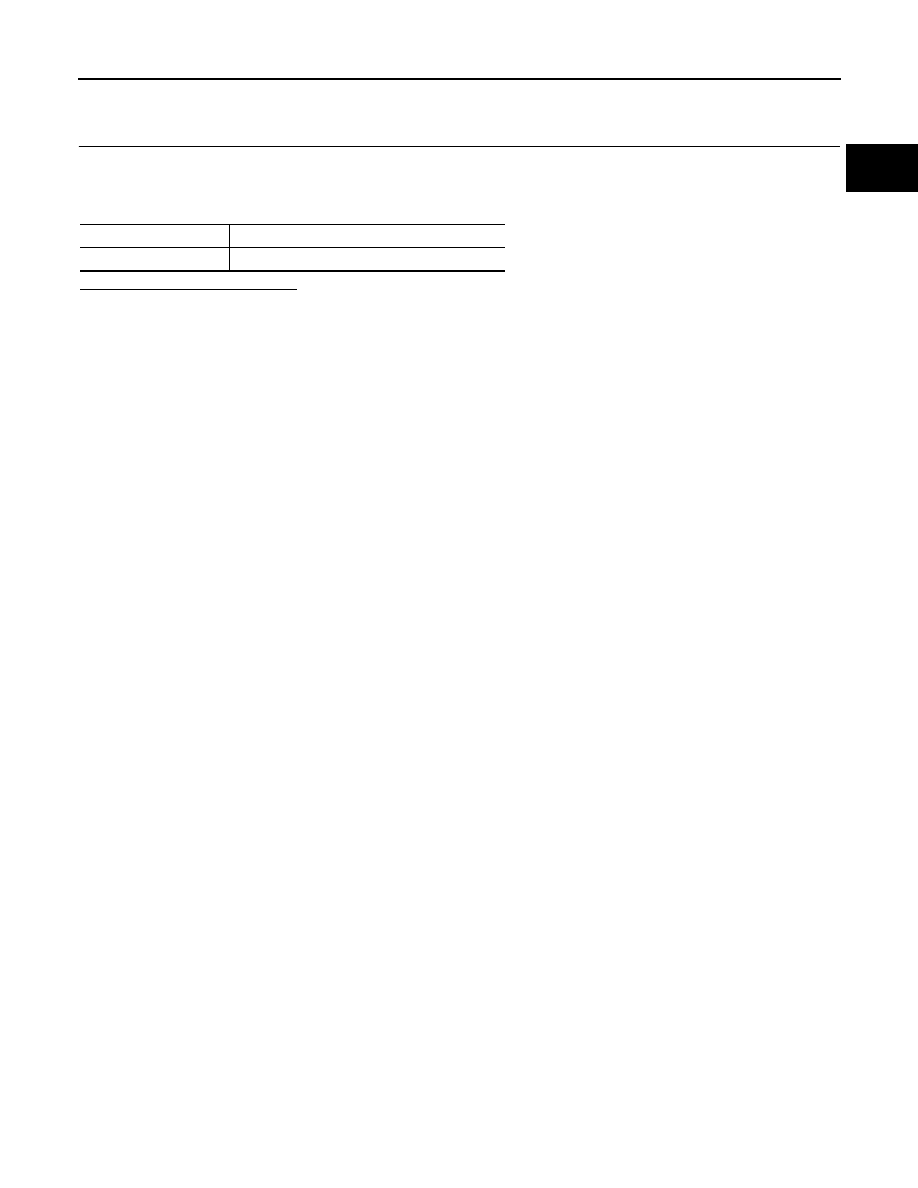

Terminals

Resistance [at 25

°C (77°F)]

1 and 2

Above 1 M

Ω