Nissan Rogue. Manual - part 986

PWC-26

< BASIC INSPECTION >

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

INFOID:0000000011278683

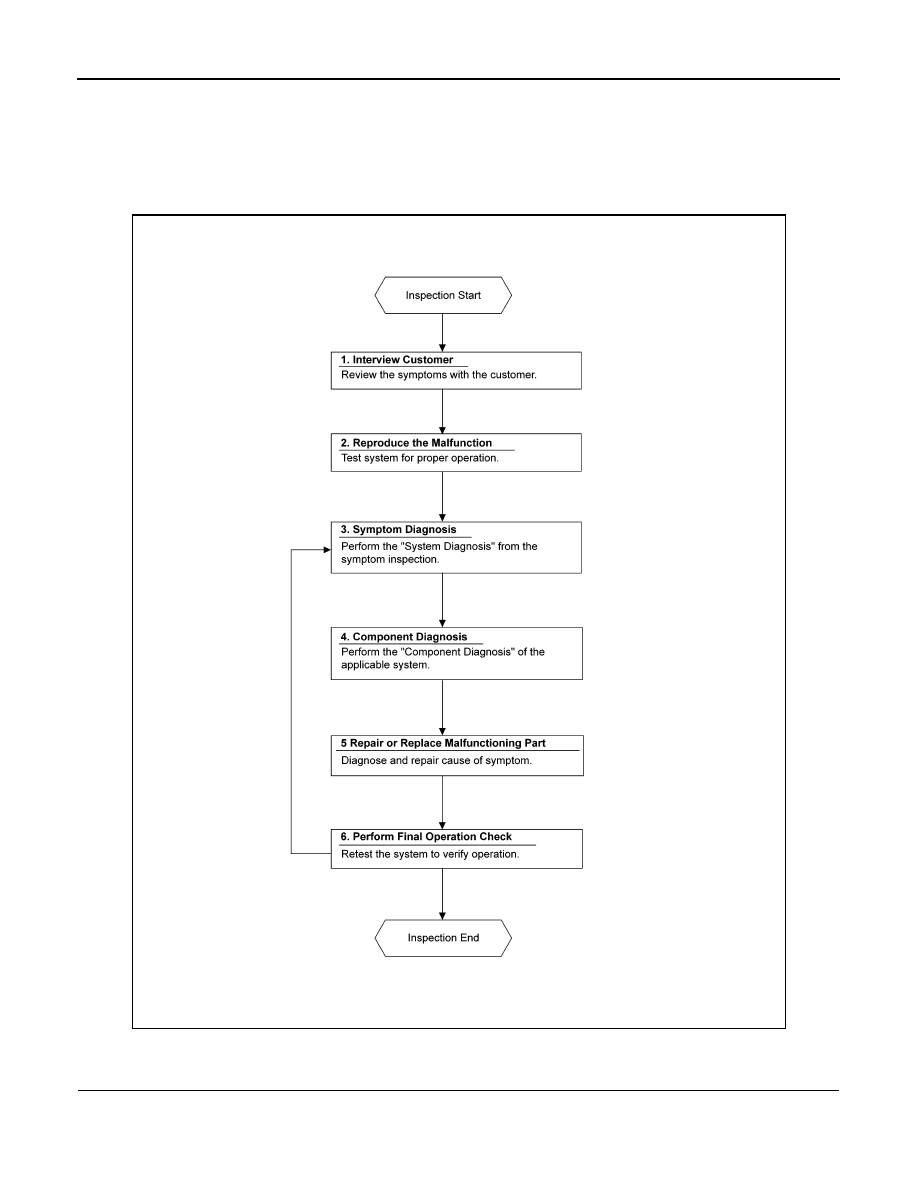

OVERALL SEQUENCE

DETAILED FLOW

1.

INTERVIEW CUSTOMER

Interview the customer to obtain as much information as possible about the conditions and environment under

which the malfunction occurred.

ALKIA1982GB