Nissan Rogue. Manual - part 721

IDENTIFICATION INFORMATION

GI-35

< VEHICLE INFORMATION >

C

D

E

F

G

H

I

J

K

L

M

B

GI

N

O

P

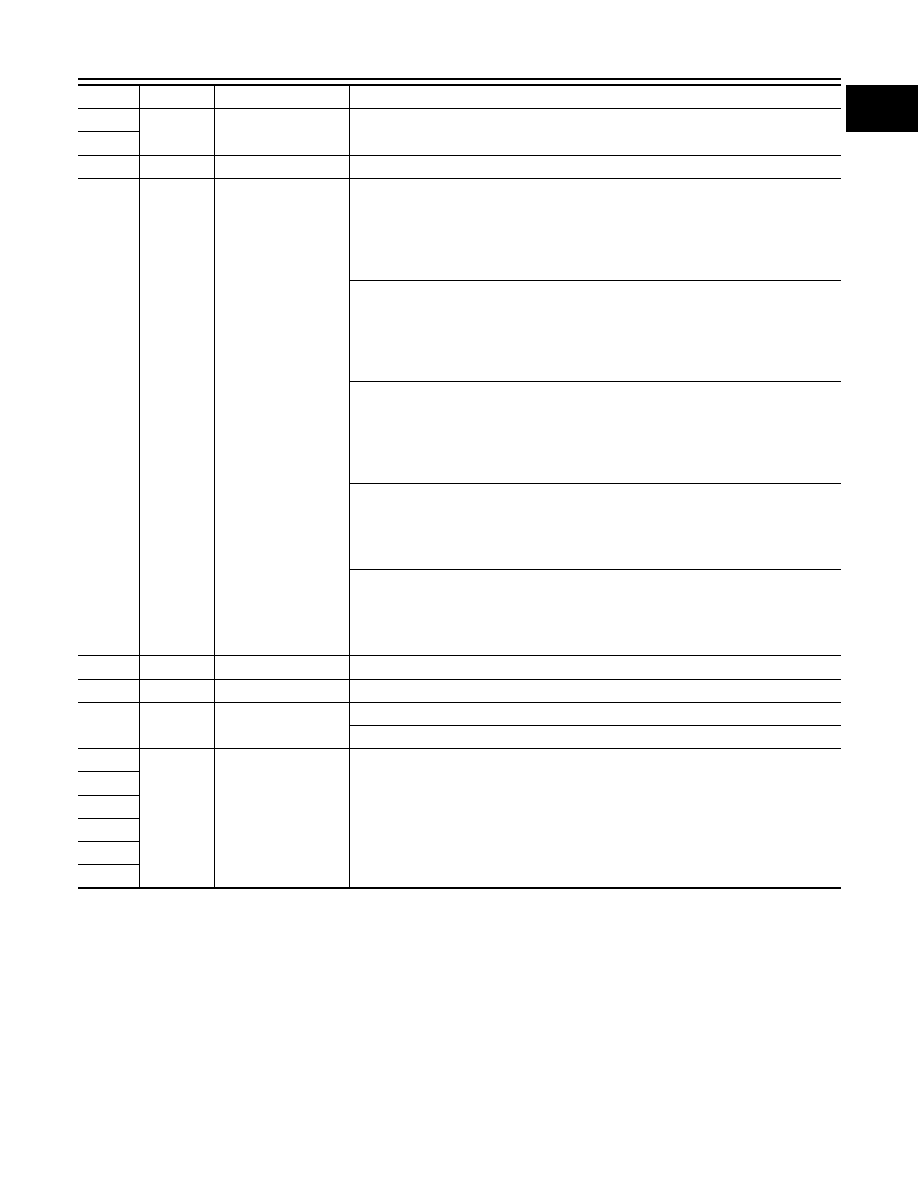

5

T2

Model series

T2: T32 (Rogue)

6

7

M

Body type

M: 4 Door Wagon

8

L

Restraint system

K: 4WD, Class C (3 row, 7 seating capacity)

• (Driver and Passenger) 3-Point Manual Belts, Frontal Air Bags, Side Air Bags and

Curtain Side Air Bags.

• (2nd Row Outboard): 3-Point Manual Belts and Curtain Side Air Bags.

• (2nd Row Center): 3-Point Manual Belt.

• (3rd Row Outboard): 3-Point Manual Belts and Curtain Side Air Bags.

L: 2WD, Class C (3 row, 7 seating capacity)

• (Driver and Passenger) 3-Point Manual Belts, Frontal Air Bags, Side Air Bags and

Curtain Side Air Bags.

• (2nd Row Outboard): 3-Point Manual Belts and Curtain Side Air Bags.

• (2nd Row Center): 3-Point Manual Belt.

• (3rd Row Outboard): 3-Point Manual Belts and Curtain Side Air Bags.

M: 4WD, Class D (3 row, 7 seating capacity)

• (Driver and Passenger) 3-Point Manual Belts, Frontal Air Bags, Side Air Bags and

Curtain Side Air Bags.

• (2nd Row Outboard): 3-Point Manual Belts and Curtain Side Air Bags.

• (2nd Row Center): 3-Point Manual Belt.

• (3rd Row Outboard): 3-Point Manual Belts and Curtain Side Air Bags.

T: 2WD, Class C (2 row, 5 seating capacity)

• (Driver and Passenger) 3-Point Manual Belts, Frontal Air Bags, Side Air Bags and

Curtain Side Air Bags.

• (2nd Row Outboard): 3-Point Manual Belts and Curtain Side Air Bags.

• (2nd Row Center): 3-Point Manual Belt.

V: 4WD, Class C (2 row, 5 seating capacity)

• (Driver and Passenger) 3-Point Manual Belts, Frontal Air Bags, Side Air Bags and

Curtain Side Air Bags.

• (2nd Row Outboard): 3-Point Manual Belts and Curtain Side Air Bags.

• (2nd Row Center): 3-Point Manual Belt.

9

*

Check digit

(0 to 9 or X) The code for the check digit is determined by a mathematical computation

10

F

Model year

F: 2015

11

C

Manufacturing plant

C: USA production

P: Korea production

12

XXXXXX

Vehicle serial number Chassis number

13

14

15

16

17

Position

Character

Qualifier

Definition