Nissan Rogue. Manual - part 511

EC-312

< DTC/CIRCUIT DIAGNOSIS >

[QR25DE]

P0441 EVAP CONTROL SYSTEM

WITHOUT CONSULT

1. Start engine and warm it up to normal operating temperature.

2. Stop engine.

3. Disconnect vacuum hose connected to EVAP canister purge volume control solenoid valve at EVAP ser-

vice port and install vacuum gauge. For the location of EVAP service port, refer to

EMISSION SYSTEM : System Description"

4. Start engine and let it idle.

Never depress accelerator pedal even slightly.

5. Check vacuum gauge indication before 60 seconds pass after starting engine.

6. Rev engine up to 2,000 rpm after 100 seconds pass after starting engine.

Is the inspection result normal?

YES

>> GO TO 8.

NO

>> GO TO 5.

5.

CHECK EVAP PURGE LINE

1. Turn ignition switch OFF.

2. Check EVAP purge line for improper connection or disconnection.

EC-55, "EVAPORATIVE EMISSION SYSTEM : System Description"

Is the inspection result normal?

YES

>> GO TO 6.

NO

>> Repair EVAP purge line.

6.

CHECK EVAP PURGE HOSE AND PURGE PORT

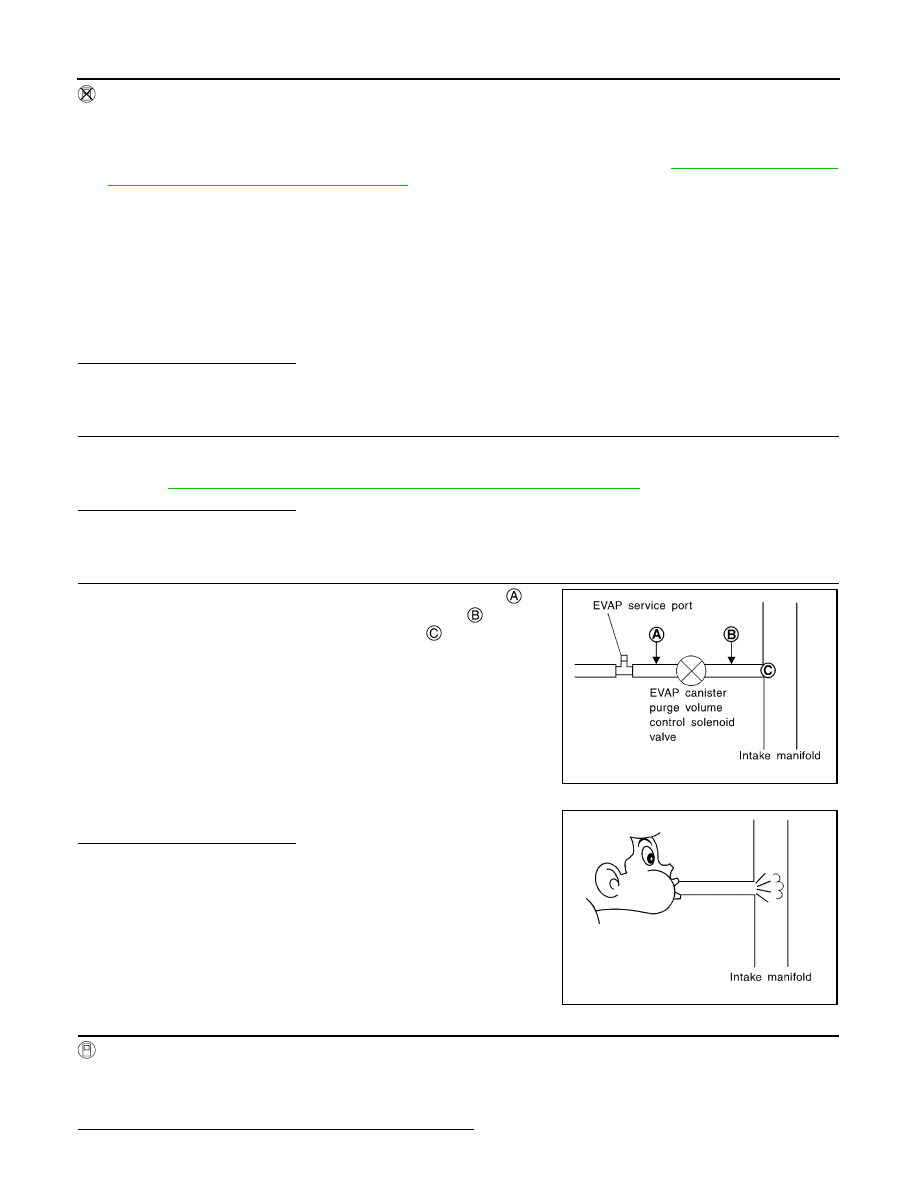

1. Disconnect purge hoses connected to EVAP service port and

EVAP canister purge volume control solenoid valve .

2. Blow air into each hose and EVAP purge port .

3. Check that air flows freely.

Is the inspection result normal?

YES-1 >> With CONSULT: GO TO 7.

YES-2 >> Without CONSULT: GO TO 8.

NO

>> Repair or clean hoses and/or purge port.

7.

CHECK EVAP CANISTER PURGE VOLUME CONTROL SOLENOID VALVE

WITH CONSULT

1. Start engine.

2. Perform “PURG VOL CONT/V” in “ACTIVE TEST” mode of “ENGINE” using CONSULT. Check that

engine speed varies according to the valve opening.

Does engine speed vary according to the valve opening?

Vacuum should not exist.

Vacuum should exist.

SEF367U

SEF368U