Nissan Rogue. Manual - part 475

EC-168

< DTC/CIRCUIT DIAGNOSIS >

[QR25DE]

POWER SUPPLY AND GROUND CIRCUIT

POWER SUPPLY AND GROUND CIRCUIT

Diagnosis Procedure

INFOID:0000000011277917

1.

CHECK FUSE

Check that the following fuse is not fusing.

Is the fuse fusing?

YES

>> Replace the fuse after repairing the applicable circuit.

NO

>> GO TO 2.

2.

CHECK GROUND CONNECTION

1. Turn ignition switch OFF.

2. Check ground connection E9 or E15. Refer to

Is the inspection result normal?

YES

>> GO TO 3.

NO

>> Repair or replace ground connection.

3.

CHECK ECM GROUND CIRCUIT

1. Disconnect ECM harness connectors.

2. Check the continuity between ECM harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> Repair or replace error-detected parts.

4.

CHECK ECM POWER SUPPLY (MAIN)-1

1. Reconnect ECM harness connector.

2. Turn ignition switch ON.

3. Check the voltage between ECM harness connector terminals.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> GO TO 6.

5.

CHECK ECM POWER SUPPLY (MAIN)--2

1. Turn ignition switch OFF and wait at least 10 seconds.

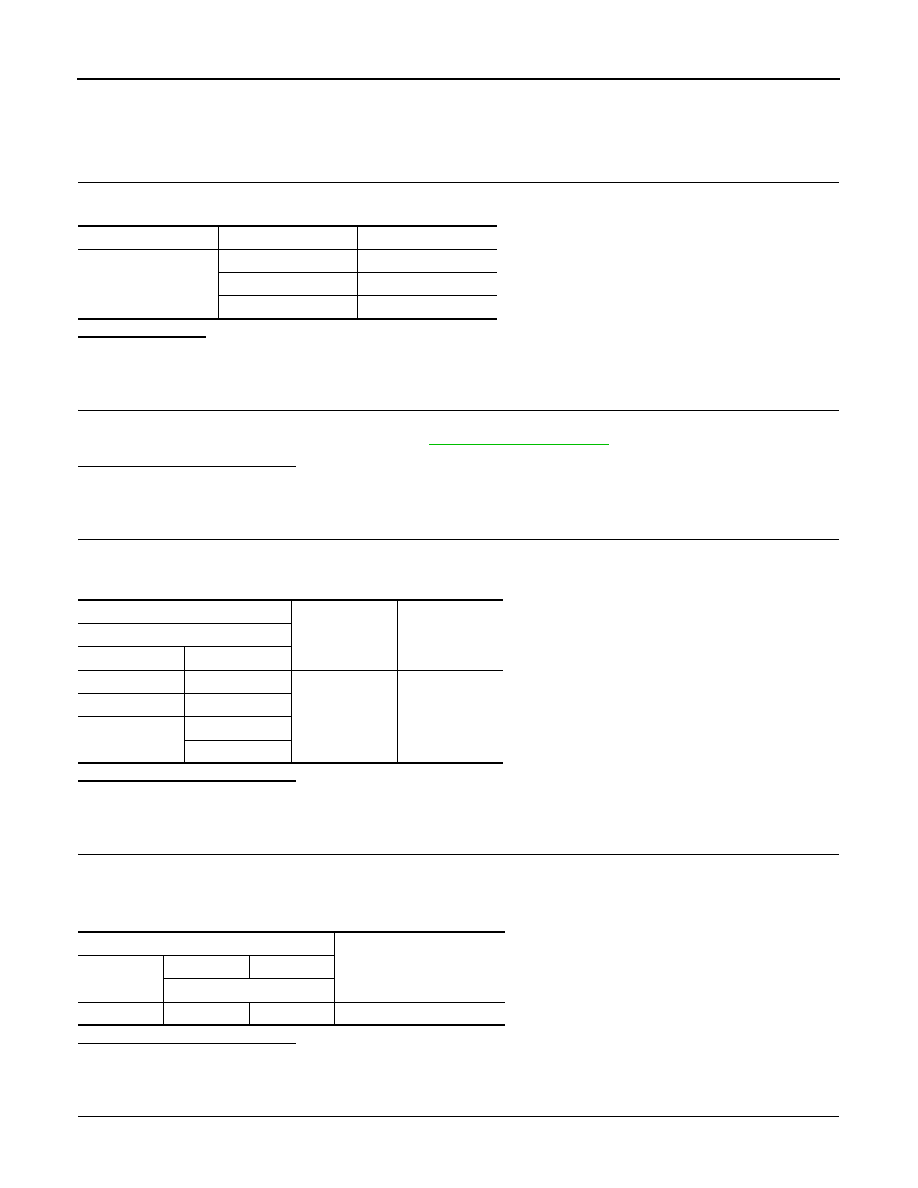

Location

Fuse No.

Capacity

IPDM E/R

#48

5 A

#41

10 A

#35

15 A

+

−

Continuity

ECM

Connector

Terminal

F52

52

Ground

Existed

F51

16

E16

123

128

ECM

Voltage

Connector

+

−

Terminal

E16

121

128

Battery voltage